BEYOND CUTTING EDGE

defense & aerospace

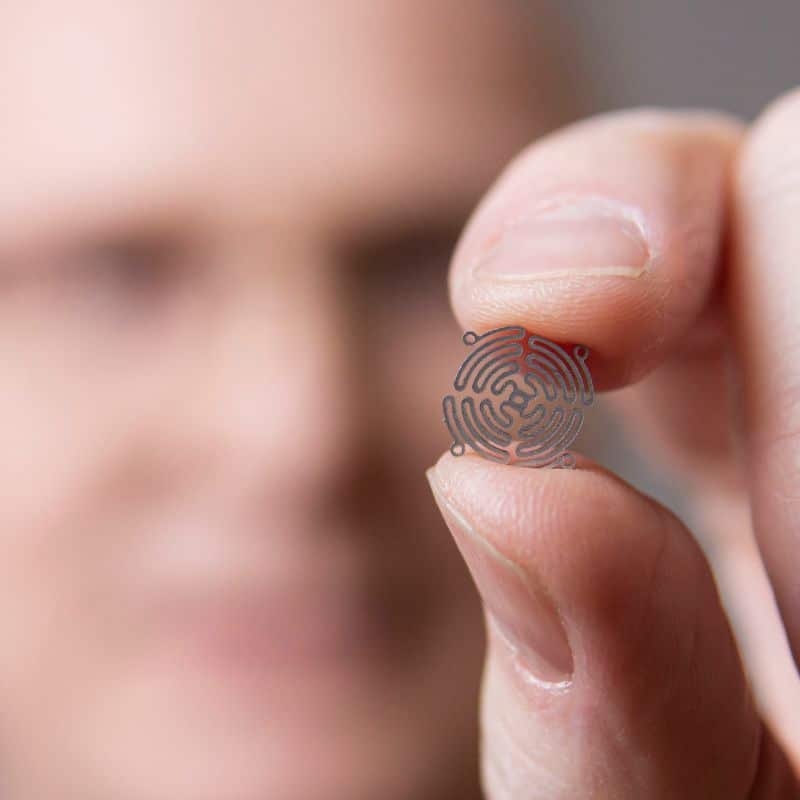

Finepart develop and manufacture the exceptional precision cutting machine technology that enables cutting of highly complex parts in advanced materials used in the defense and aerospace industry.

Applications in the Aerospace & Defense Industries

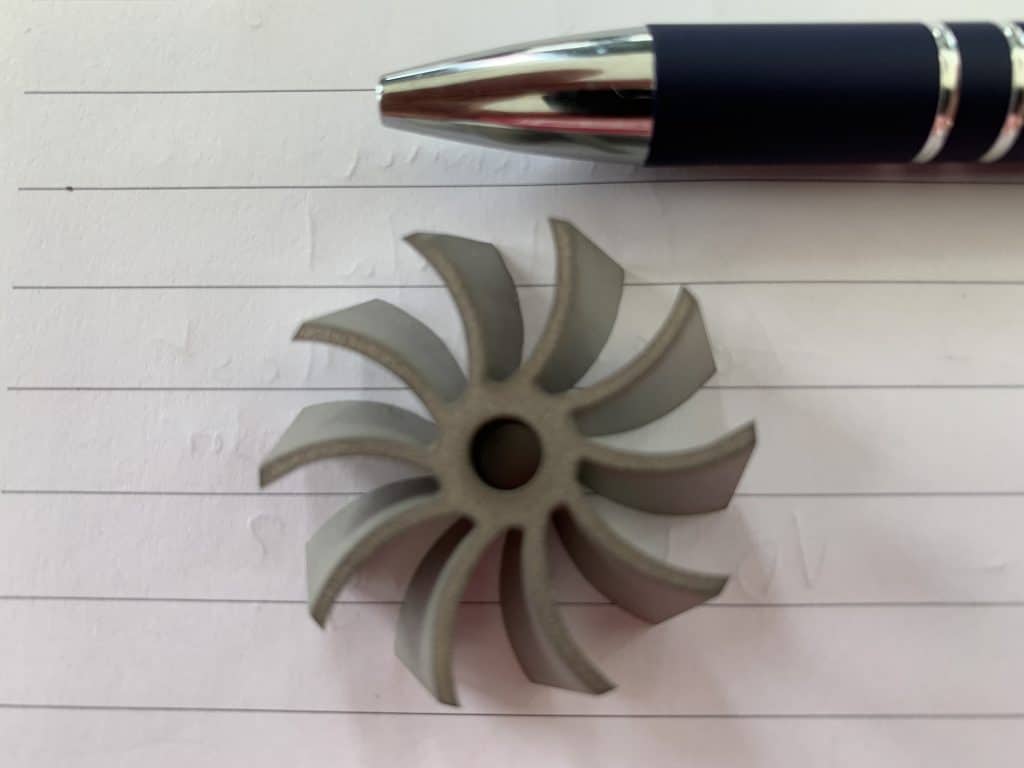

The use of micro abrasive waterjet cutting in the aerospace and defense industry is the creation of precision parts for a variety of equipment components.

- Aircraft engine components

- Helicopter engine components

- Firearm components

- Armour (bullet proof plates, helmets)

Precision Cutting With Exceptional Accuracy & Quality

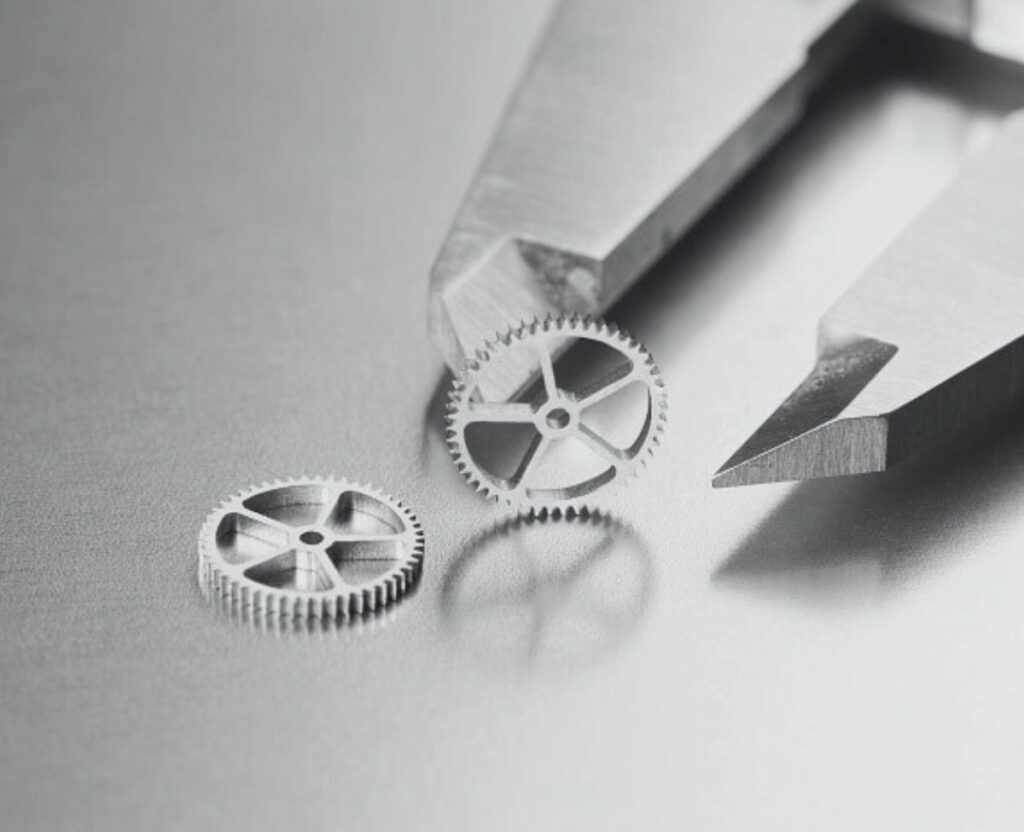

Finepart precision cutting technology provides the highest accuracy and tighter tolerances than any other cold-cutting technology:

Finished part tolerances ± 10 µm

Positioning accuracy: ± 2,5 µm

Jet kerf: 200 µm

Cutting speed: upto 20 m/min (787″/min)

Highly advanced control and automation system

No heat-affected zone, burrs, or micro-cracks

The World’s most accurate cold cutting technology

The Finepart precision cutting technology is the most accurate cold-cutting technology available today

As manufacturer in the defense and aerospace industry rely on high precision cutting of advanced material such as aluminum, titanium, and advanced composite materials.

The Finepart micro abrasive waterjet technology is the optimal technology for ultimate edge quality and eliminate material distortion such as heat-affected-zones, burr and micro cracks, which is absolutely essential for parts integrity in the defense and aerospace sector.

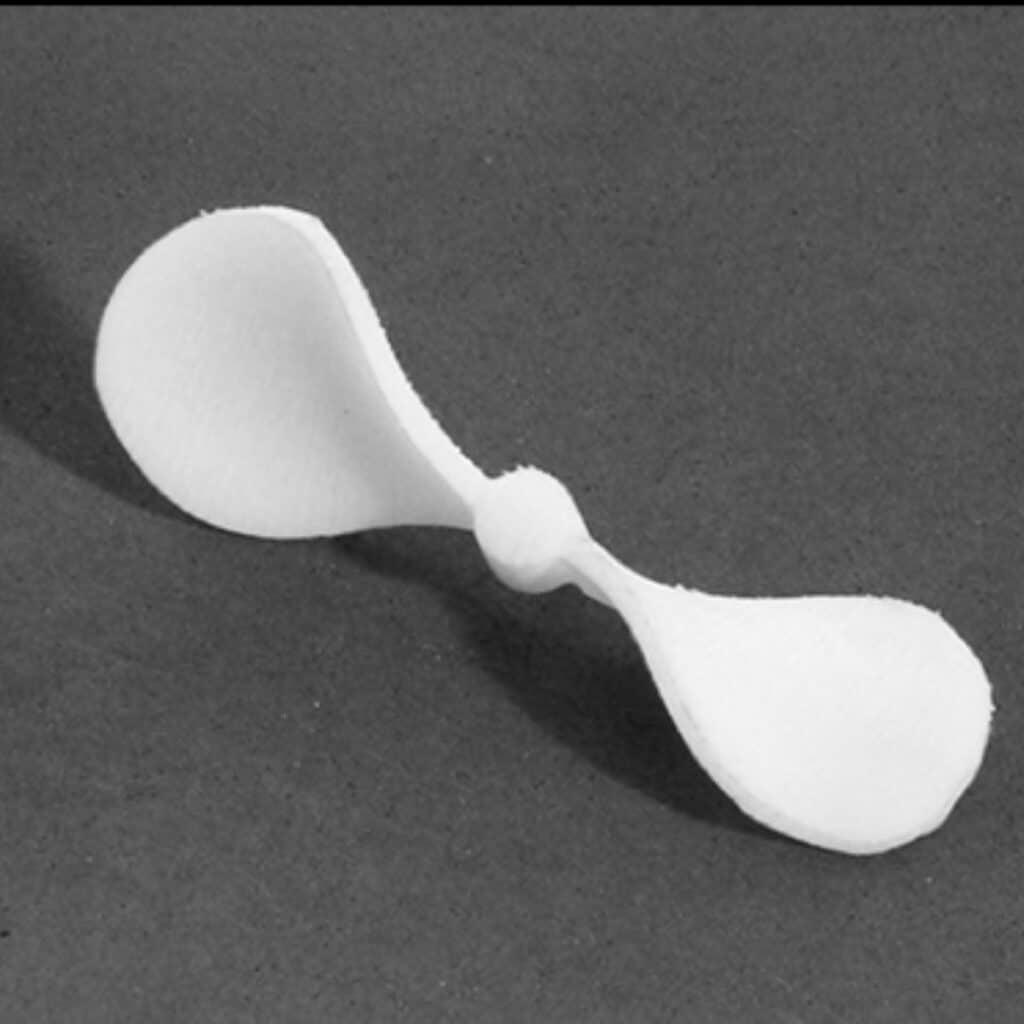

Designed for Fast Prototyping & Volume Production

Prototyping capabilities to mimic final parts tolerances and quality is essential for fast innovation. Finepart helps make fast and precise prototyping easy and cost effective.

Any Finepart machine can be converted from production set up to prototyping machine in minutes for increase iterations, shorter lead-time, and avoid the significant cost increase of a dedicated prototyping machine.

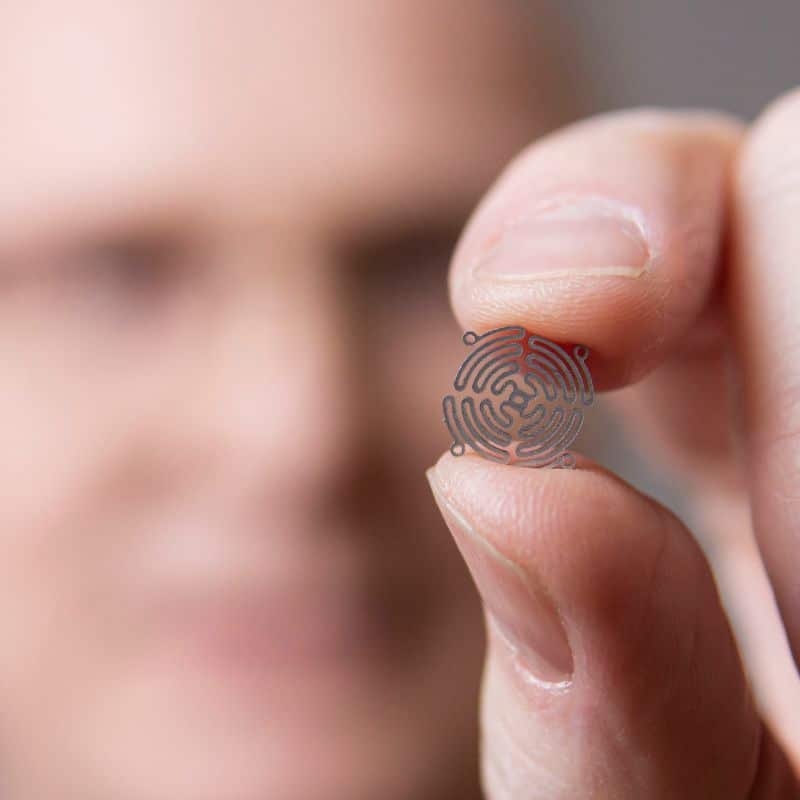

Cuts Any Advanced material

Finepart machines are tried and tested on the most advanced materials. The Finepart advanced CAD/CAM software and machine operation software includes all advanced material data and automatically adjusts for required tolerances, positioning accuracy, automatic perfect alignment, and taper elimination to make precision cutting easy in any advanced material.

Metal alloys (titanium, aluminum, nitinol)

Composites (CFRP)

Plastic composites

Ceramics and brittle materials

Amorphous metals

Multi-layer materials

Speak With A Waterjet Specialist

About Finepart

Tailor your precision cutting to match unique precision, quality and productivity requirements, or need for automation, and multi-machine production setup.

Innovation … our mission and progress (the most accurate cold cutting technology

Finepart is under strict export control …

About Finepart Environment, Social Responsibility, Corporate Governance

Brief description, link to blog articles, for further information please contact us.

This requires a clear definition of what ESG means for Finepart, Goals, and actions (planned and completed).