BEYOND CUTTING EDGE

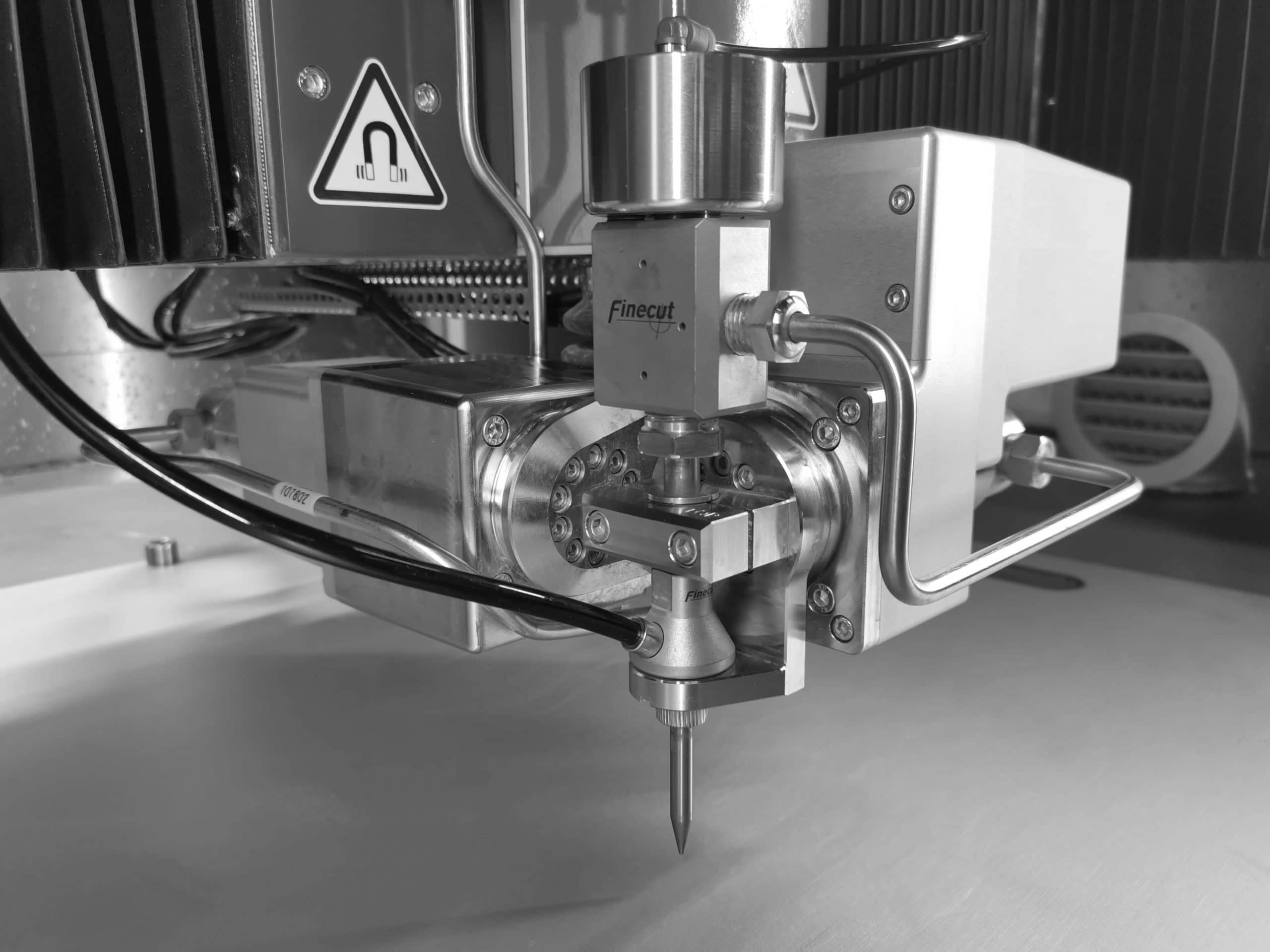

High Precision Cutting With Micro Waterjet

Finepart delivers the high precision cutting machinery needed for ultimate precision and quality of high complex shapes, in advanced material … fast.

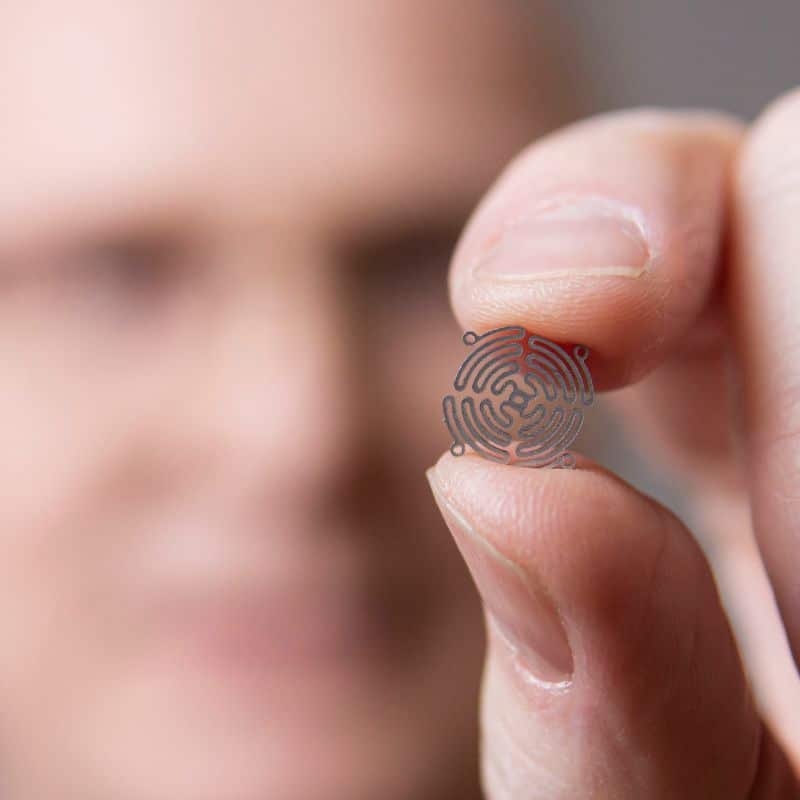

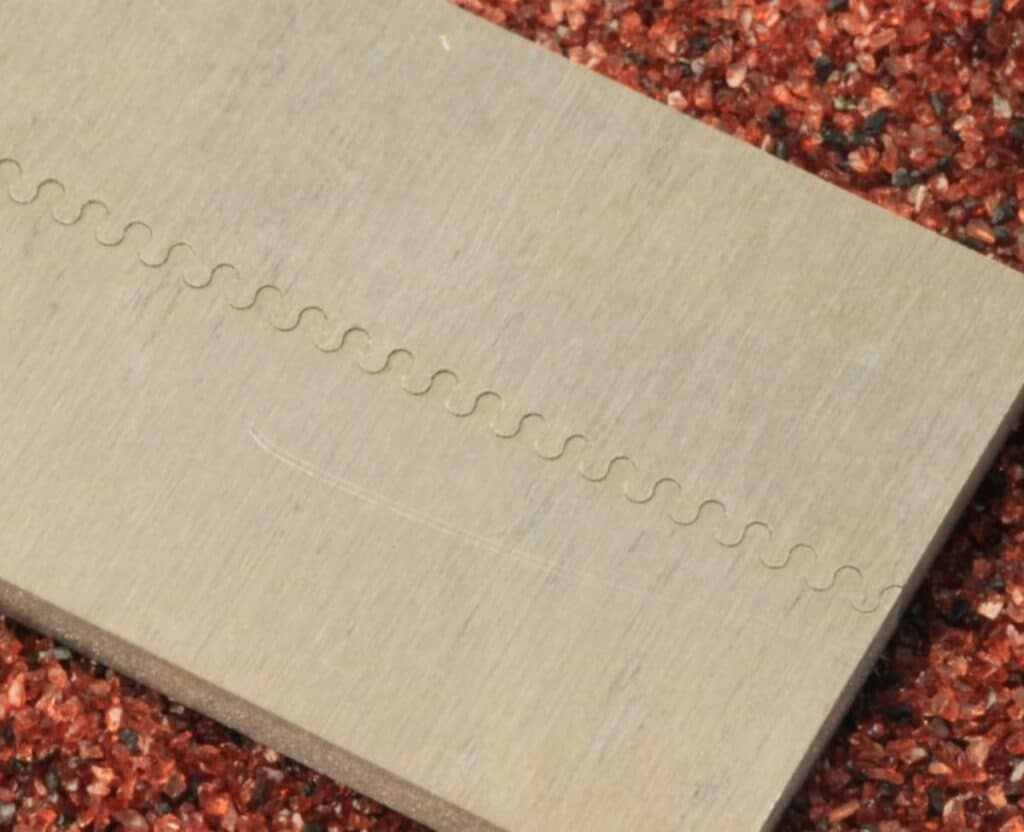

Ultimate-precision cutting of complex shapes

Precision cutting machine technology that allows you to create complex shapes in 2D or 3D, with demanding tolerances ± 10 µm, in ultimate surface quality.

- Cutting width: 0.2 mm – 0.5 mm

- Cutting tolerance: ± 10 µm

- Positioning accuracy: ± 2,5 µm

Very tight tolerances

Ultimate edge quality

Micro kerf

Cut both micro parts and larger parts

Defies the limitations of materials

Cut through advanced materials with unparalleled precision.

- Metal Alloys (titanium, aluminum)

- Shape memory alloys (nitinol)

- Amorphous metals

- Brittle Materials

- Composites (CFRP)

- Engineered Ceramics

- Sandwich Materials

Finecut software that makes you a precision cutting champion

Every Finecut comes with proprietary Human Machine Interface (HMI) and CAD/CAM software that provides you with ultimate control and optimize your cutting processes, ensuring the highest cut quality with ease. Finepart puts precision at your fingertips.

Benefits of Finepart precision cutting technology

Probably the most accurate micro abrasive waterjet machine money can buy

- Fast cutting of high value, complex precision parts.

- Micro kerf allows unparalleled 3D detail

- No thermal impact

- Ultimate edge quality in one single-pass cut

- Multi-machine set up for volume fabrication

- Fast prototyping

- Net or near-net cutting, little or no hand finishing

Speak With A Waterjet Specialist

Endless options for enhancement

Tailor your precision cutting to match unique precision, quality and productivity requirements, or need for automation, and multi-machine production setup.