What material can a micro abrasive waterjet cut?

We cut your material no matter if it is very soft or ultra-hard or anything in between.

Accurate non-thermal cutting for virtually all materials

Finepart offers high-precision micro abrasive waterjet machines for cutting of all materials without using high temperatures – which leads to no distortion of material properties. Below follows a list of material groups that we commonly work with. Can you not find your material? Do not worry, we can in all likelihood cut it.

Composites

Often high-strength materials, where high-strength fibers reinforce a base material. The base material is often light but with a low strength. With an addition of fibers (glass, carbon fiber, metal) a high strength can be achieved with a good weight / strength ratio. Water cutting is suitable as it cuts both material types cleanly (no fiber rip outs or melting) and does not cause any problems.

Examples: reinforced plastics; carbon fibers (CFRP), glass fibers, Kevlar, Zylon, Aramid and metal matrix materials.

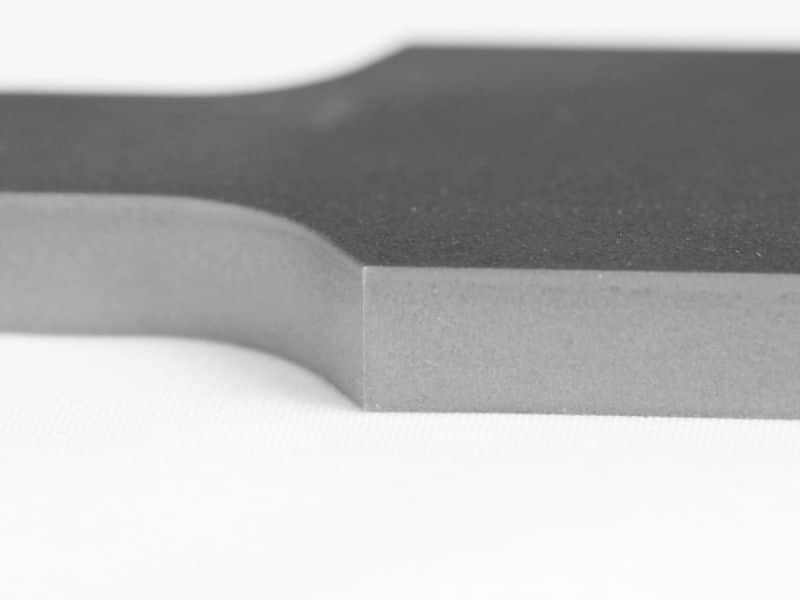

High strength metal alloys

With the help of alloying elements and heat treatments, you can create a material structure that provides the desired strength. When these materials are being processed, to avoid the material structure to be transformed, it is important that the process does not add heat. Our process is cold and is therefore suitable for all these alloys.

Examples: titanium, nickel alloy, shape memory alloys (e.g. Nitinol), magnesium alloy, hardened steel, Hardox, Inconel, tool steel.

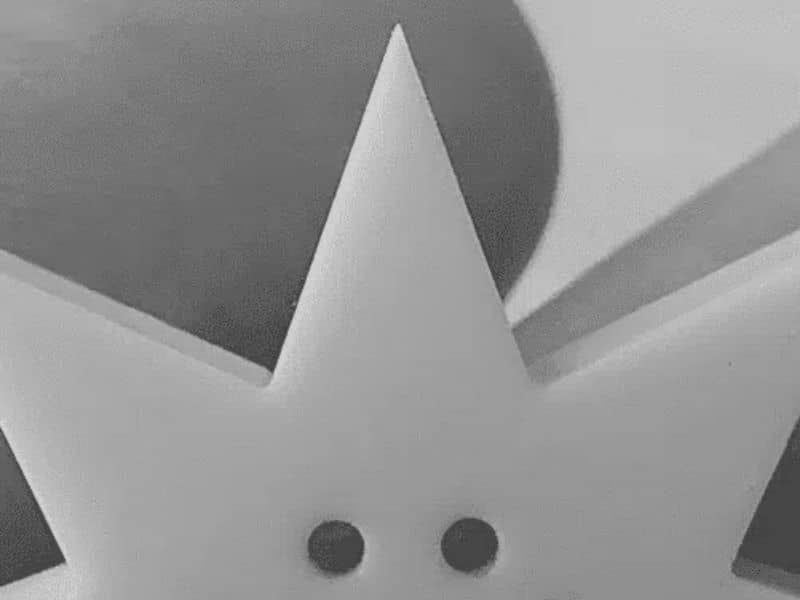

Hard materials

Many engineering ceramics are extremely hard which give them high strength and excellent wear resistance. These features make them hard to machine. The traditional way to machine is to use a tool that is significantly harder than the material to be machined. Dimond tools are commonly used but they have limitations in how complex geometries that can be machined. Our process is based on particle erosion and erosion mechanisms are not entirely dependent on hardness which make the process capable to also remove this type of materials. The small jet diameter enables also very complex geometries.

Example: engineering ceramics, zirconia, alumina, crystal sapphire, silicon carbide, minerals.

Brittle materials

Brittle materials are often hard materials with low strength. High cutting forces can load the material over its breaking point. The material breaks easily, or you get big chippings on the edges when it is traditionally machined. Waterjet on the other hand is erosion based and will give sufficient eroding power to remove material without creating a high load which could break the part.

Example: glass, silicon, green state ceramics, mother of pearl.

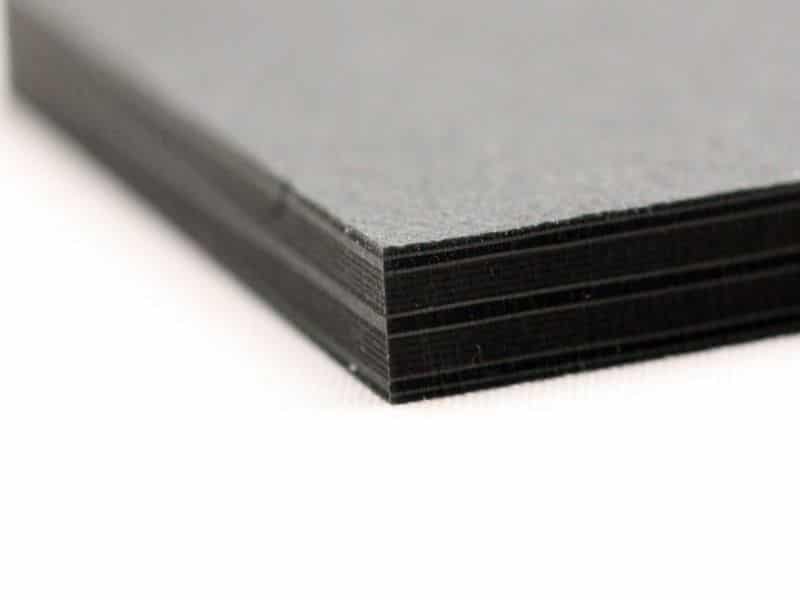

Sandwich materials/combined materials

Sandwich materials is a special class of composite materials that is fabricated by attaching two thin but stiff skins to a lightweight core. The core material is normally low strength material, but its higher thickness provides the sandwich composite with high bending stiffness with overall low density (a way to create extreme properties).

Example: Combinations of CFRP/aluminum, honeycomb structures, metal composite material (two thin metal skins with a plastic core).