Options

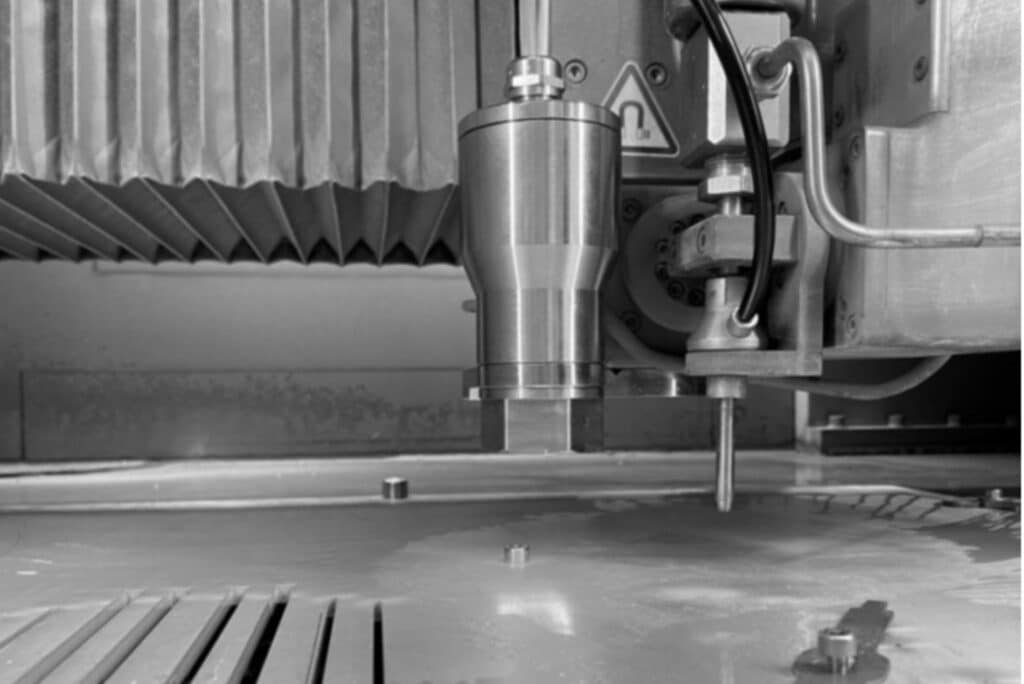

Finespin®: Polishing, Deburring & Washing

Finespin® is an excellent machine for deburring, polishing and washing small finished parts of complex geometries. With a very fine polishing media it polishes inside very narrow holes, thin slots and fine crevices where conventional polishing machines cannot reach. It works with any type of materials such as steel, stainless steel, brass, copper, aluminium, light metal alloy, hard plastic, gold, silver and platinum.

Does not deform work pieces

Does not damage part surfaces

Does not affect the parts tolerances

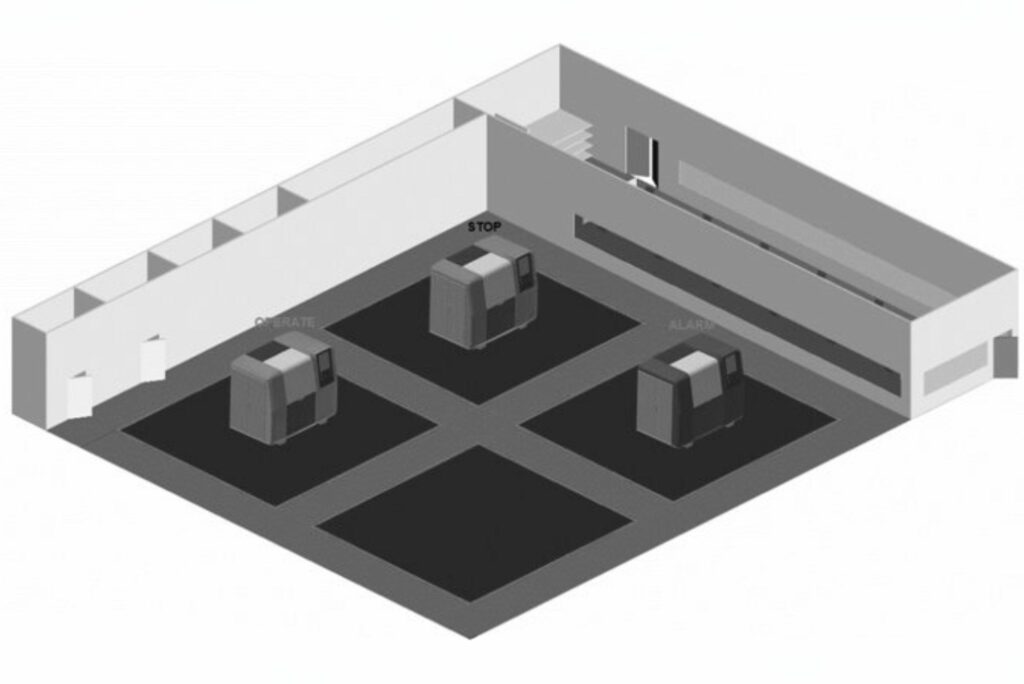

Options No. 6001700

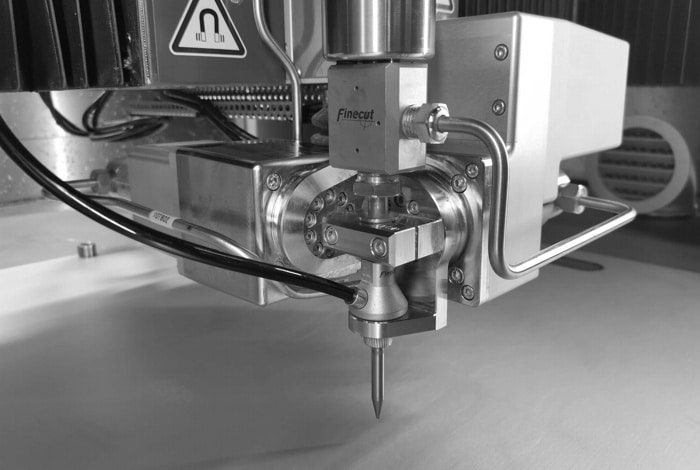

Operates With Fine Polishing Media

The process for deburring and edge rounding is based on fine impact polishing of small magnetic pins. The pins are activated by a rotating and alternating magnetic field that make them spin and wiggle as they find their way into the finest crevices of your part.

It is very easily operated, just put your parts in a container with pins on top of the machine, add some polishing fluid and push the start button. The machine will work your part to nice and shiny finish and soften the edges quickly. With the use of two containers there will be virtually zero load and unload times. Small parts can be deburred quickly and easily.

Does Not Affect Dimensions

Non-abrasive and does not distort the part or affect the tolerances.

Very small stainless steel pins are brought into motion by a magnetic field and innumerable collisions happens between pins and components in all direction and processes the surface in the finest nooks and crannies, to round edges, remove burr, and cleans the components in one single operation.

The pins come in different sizes down to 0.2 mm i diameter and can get into very tiny corners and cavities. A polishing fluid contributes to the polishing effect and keeps the components cool.

Very delicate and fragile parts that mush not touch each other can be polished in a fixture.