Process Automation & Monitoring

For high productivity manufacturing Finepart offer solutions to adopt the Finecut machine to robot assistance.

Custom solutions on inquiry

Finepart automation solutions

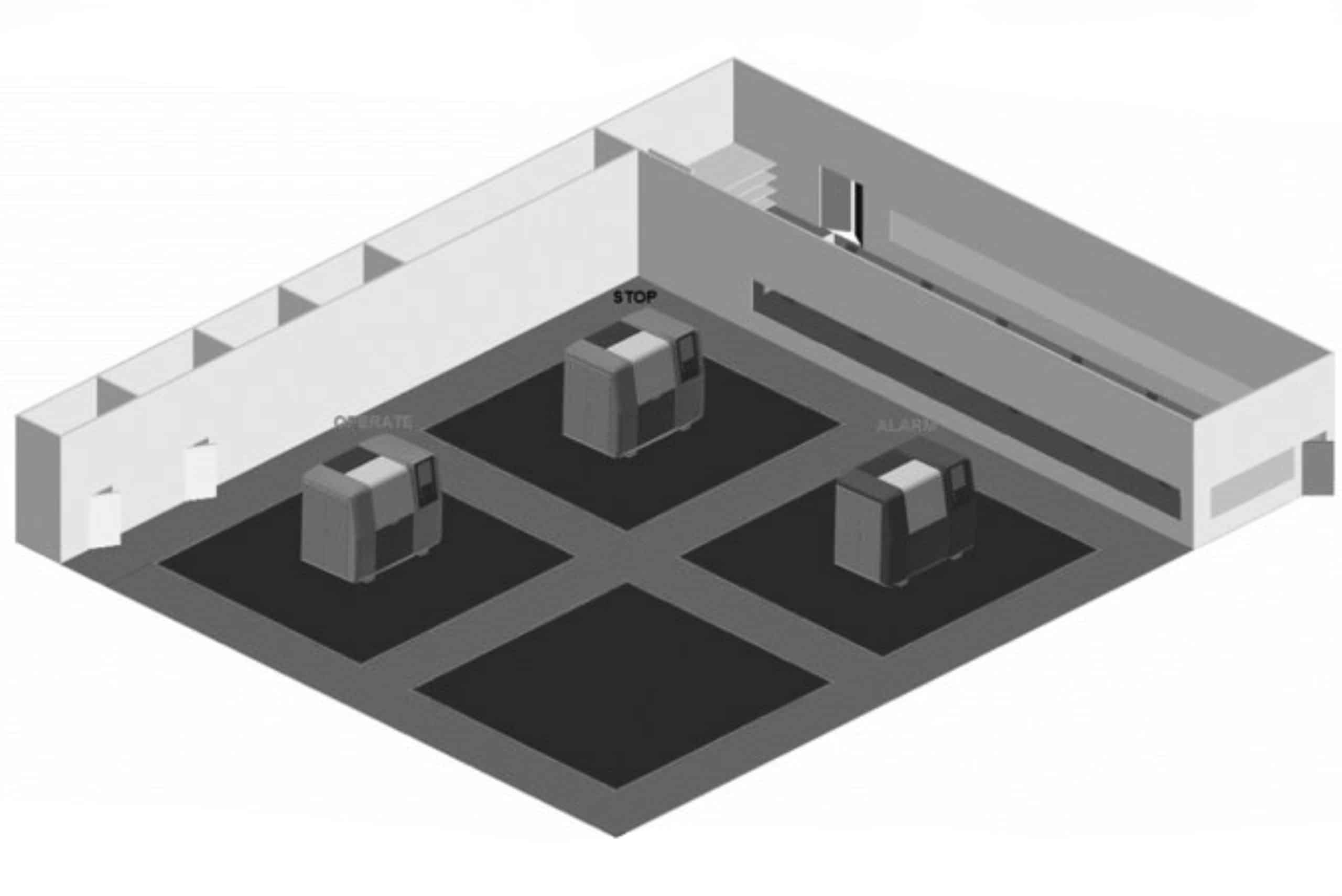

For high productivity manufacturing Finepart offer solutions to adopt the Finecut waterjet machines for robot assistance.

Automation solutions are custom made but typically features the following:

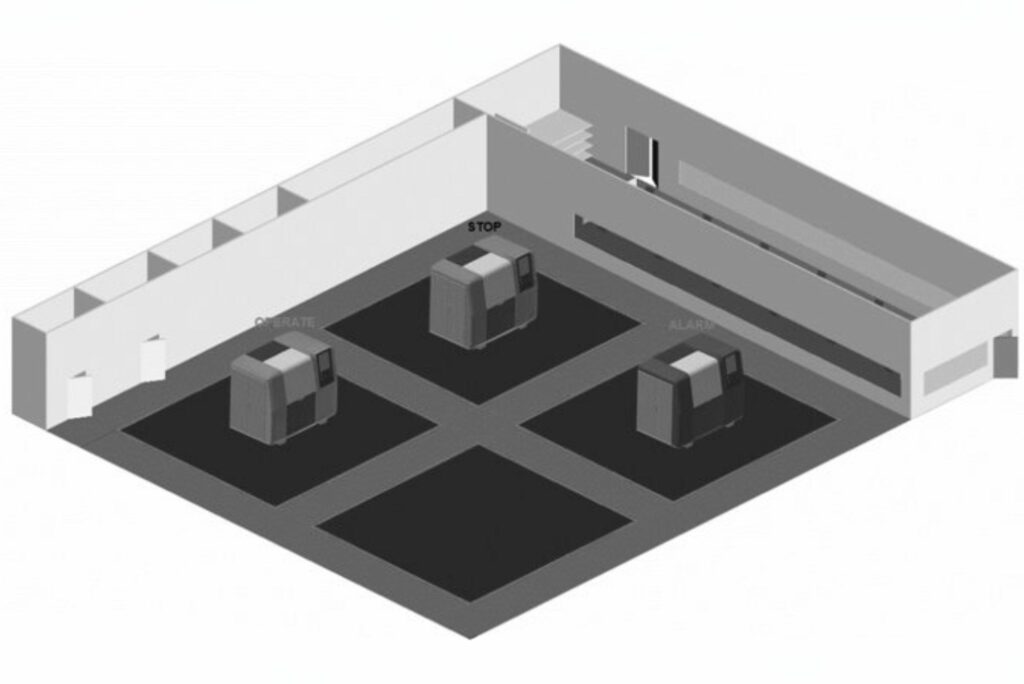

Robots are placed at the rear of the Finecut machine to simplify safety arrangements

Robots access the Finecut machine work area through the automatic backdoor.

Programming, monitoring and maintenance is conveniently made from the front.

Automation projects typically involve a local third party of customer’s choice.

Options No. 6007000

Finepart machine monitoring

FANUC [MT-LINKi] enables machine monitoring of up to 20 Finepart machines

MT-LINKi allows you to review the operational results on machine level and machine group level. You can review the production results and compare them against the production plan. You also can check machine utilization and find machines that are under-utilized. This enables you to optimize the factory’s resource planning.

Benefits

Identify alarm causes quickly, identify and cut off recurrent alarm causes

Reduce downtime by reacting quickly to abnormal states

Check machine utilization and machine productivity, detect unused production capacity

Identify deviations from the production plan easily

To include high-pressure pump monitoring a specific module can be easily added.

Options No. 6007100

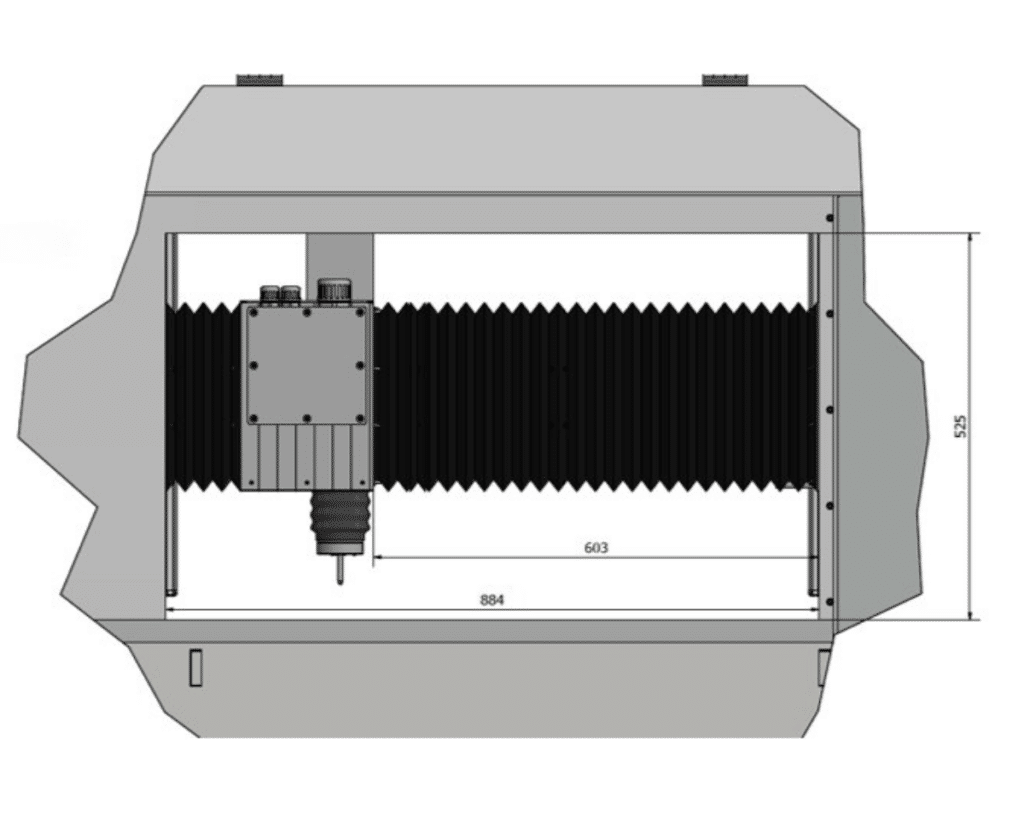

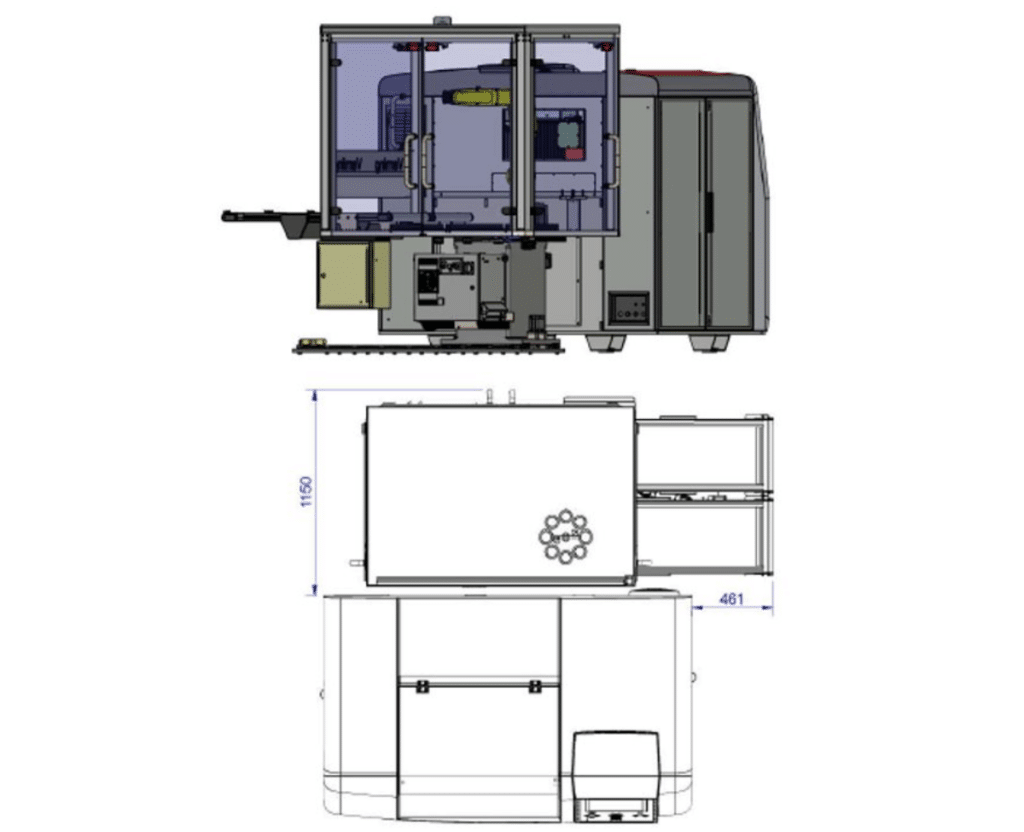

Automated backdoor for robot access

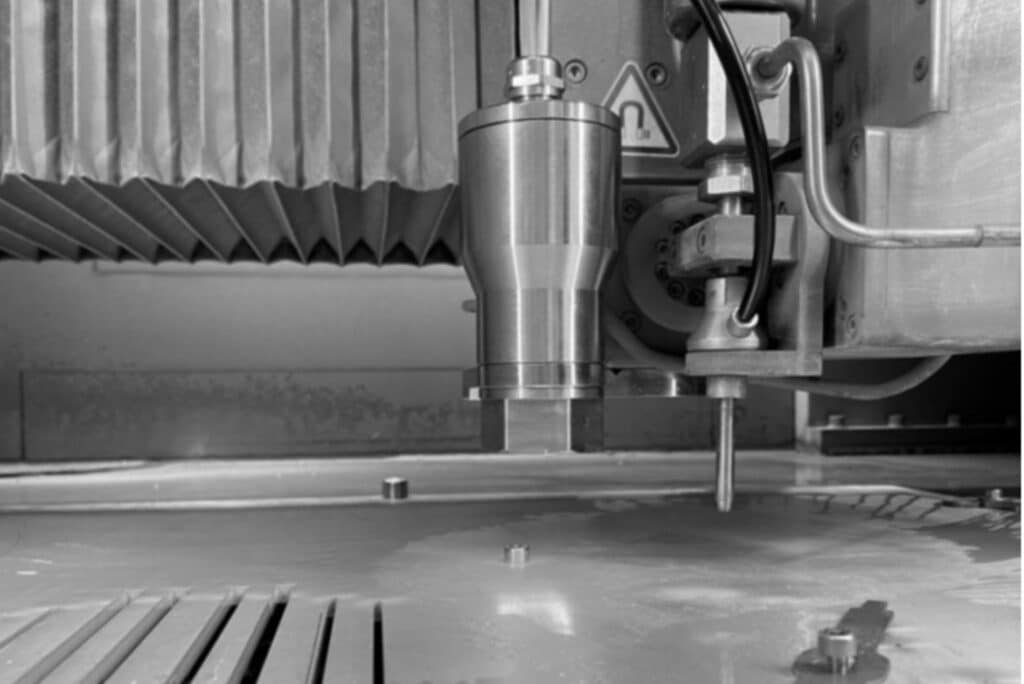

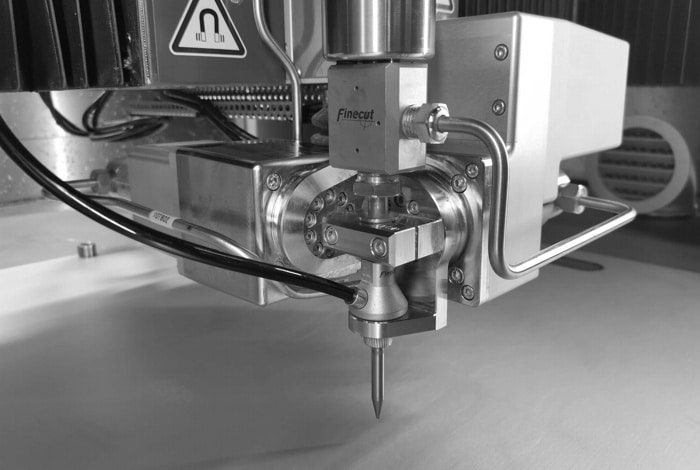

For automation the Finecut machine is preferably served by robot assistance from the back side. This gives the operator perfect overview of the process and simple access to service consumables and wear machine parts. A robust motorized curtain opens and closed within a second giving access to the machine work area.

The FANUC controller communicates with the robot for:

Loading part material on to the cutting table

Unloading of finished parts

With the robot placed at the back, operator safety is easily obtained by fences without limiting access to the machine’s service areas.