Cutting Systems

Options for single and dual cutting head to optimize precision, cutting power, and cutting speed.

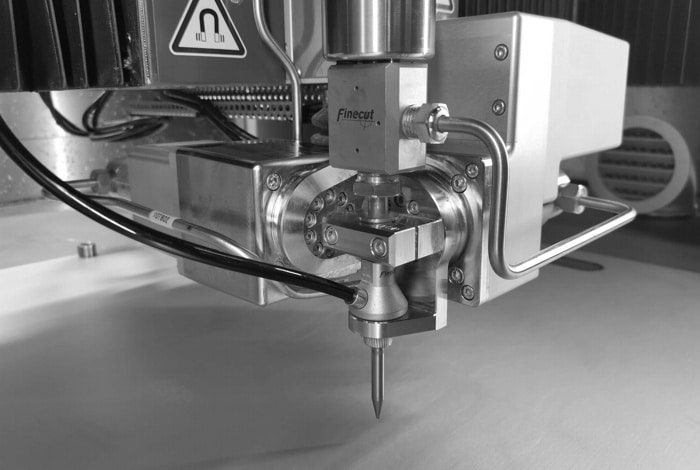

Cutting heads for optimal precision & productivity

Switch between cutting heads on-the-fly to seamlessly balance precision and power, ensuring optimal performance and productivity for every project.

Finepart Nozzles (focusing tubes)

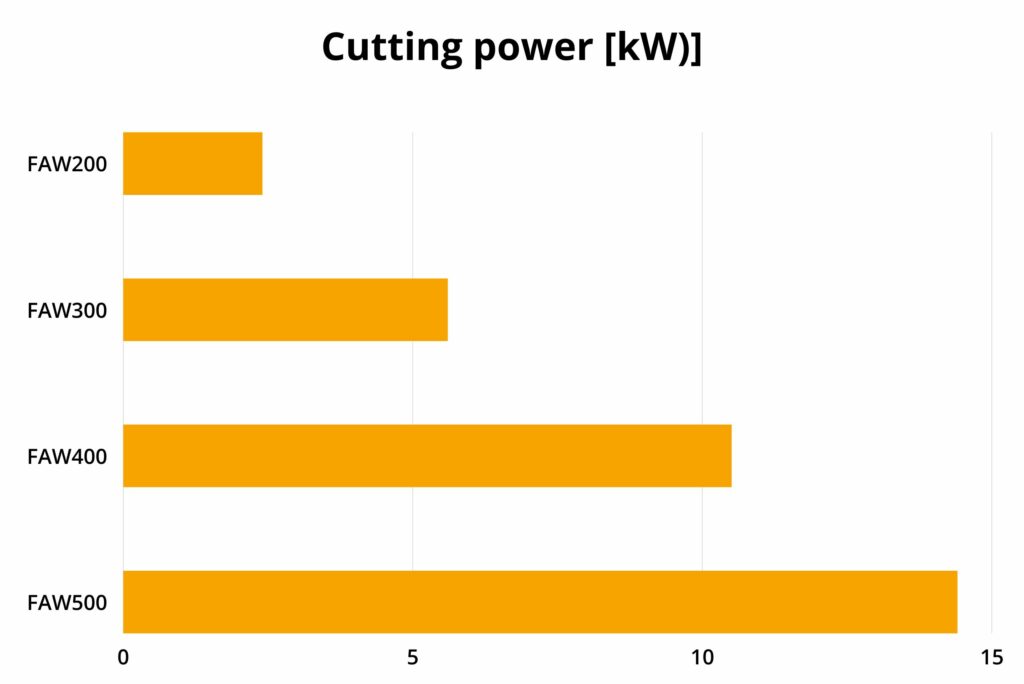

| FAW200 | FAW300 | FAW400 | FAW500 | FAW500XL | |

|---|---|---|---|---|---|

| Part no. | 6001000 | 6001050 | 6001100 | 6001150 | In development. |

| Nozzle (focusing tube) | 0,02 mm (0.00078 in) | 0,03 mm (0.0012 in) | 0,04 mm (0.0016 in) | 0,5 mm (0.002 in) | |

| Jet Power | 2,4 kW | 5,9 kW | 11 kW | 15 kW | |

| Water consumption (ltr/hrs) | 11,4 | 28,8 | 57,7 | 72 | |

| Abrasives consumption (gram per minute, mesh size #230) | 8-9 | 30 | 50-60 | 100-150 | |

| Benefits | For the finest features available for micro cutting | World class cutting of very fine tolerances. | Powerful cutting jet to enhance productivity. | High cutting speed and increased productivity. |

Cutting power when you need it

With the Finepart cutting head options you have full control over cutting power, precision, and productivity.

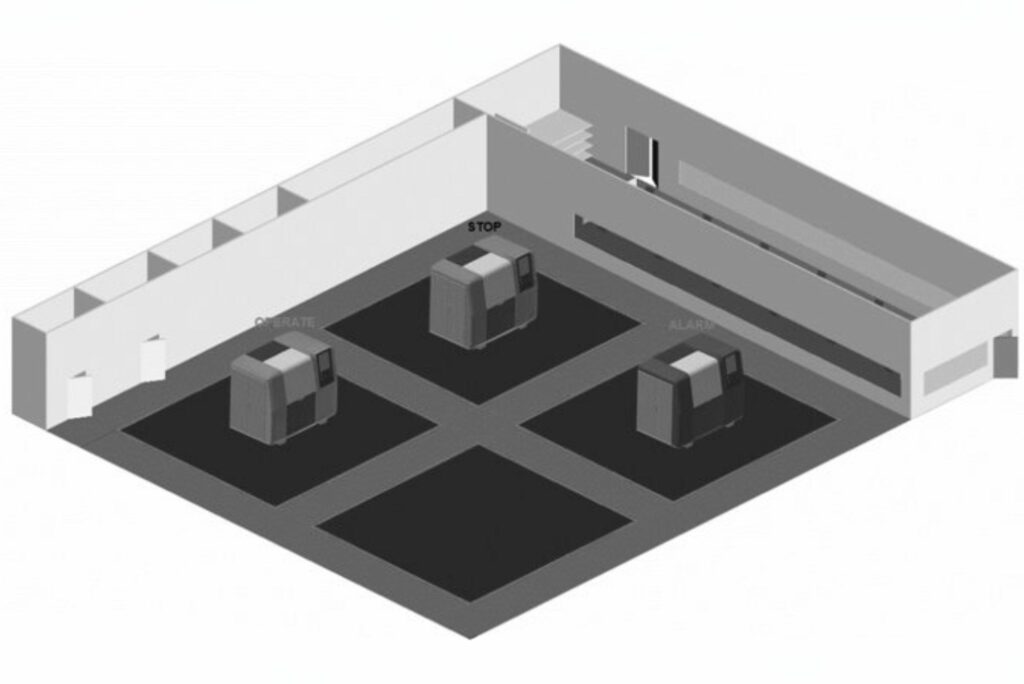

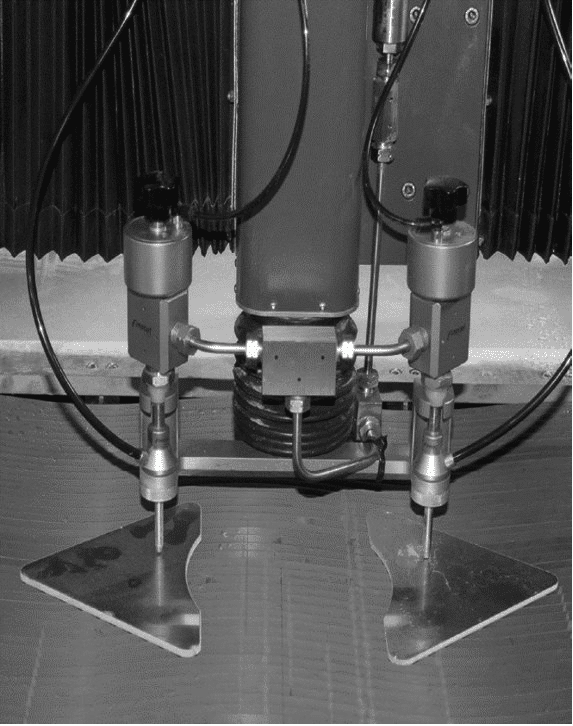

Dual cutting head

Double the cutting speed and productivity with dual cutting head

The Finecut micro waterjet machines can be equipped with dual cutting heads. This enables two systems in parallel to perform cutting of the same geometry. This option offers the opportunity to double the part production rate. The system can be run with one or two jets depending on your current needs by a simple selection in your Finesoft software.

Fitting double cutting head assemblies requires two abrasive feeders. Cutting parts with dual head implicates some loss of precision as individual radius tool compensation can not be fully realized for both heads.

The Dual cutting head kit includes:

- Finesoft dual head software plugin,

- Complementary cutting head assembly including high-pressure connections and customized tool holder.

- Complementary abrasive feeder with holder.

The dual cutting head option can not be combined with the 5-axis option.

Speak With A Waterjet Specialist

PRO range kit for any cutting requirement

The PRO range system assemblies kit will help you to be ready to take on any part in the range of what the Finecut micro waterjet machines are capable to accomplish.

The PRO range kit includes one of each

- FAW200 cutting system

- FAW300 cutting system

- FAW400 cutting system

- FAW500 cutting system

Retrofit a set of nozzles to duplicate any size of cutting system for redundancy and quickly replace a cutting system in need for maintenance.

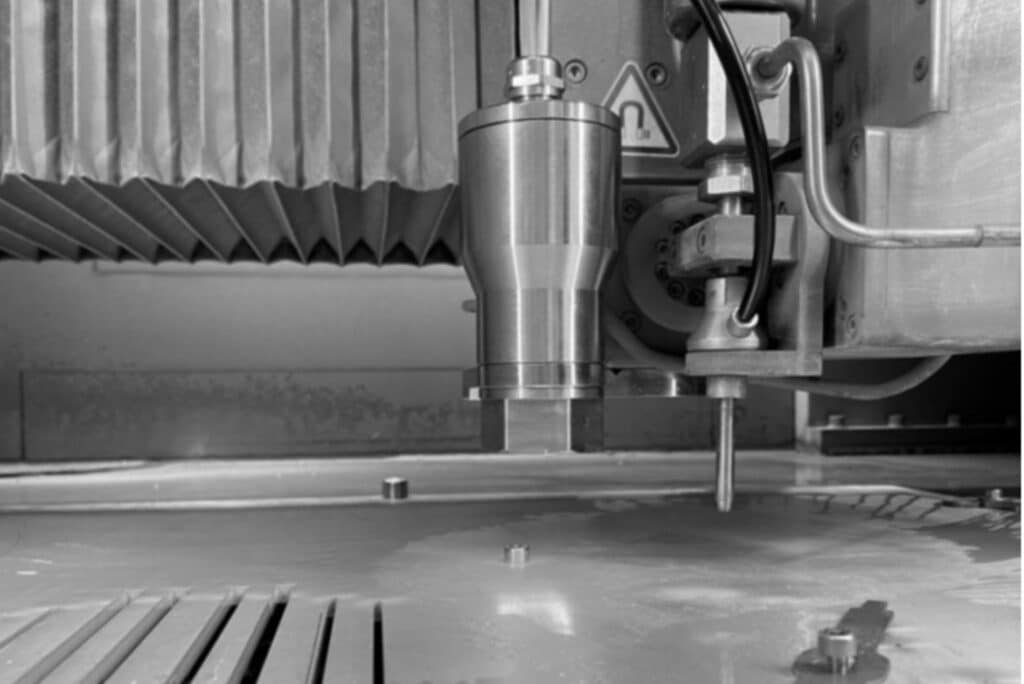

Nozzle for pure water jet cutting

Pure waterjet cutting system can generally be used for cutting soft materials such as plastics, rubber, food products, etc.

The pure waterjet cutting system does not utilize the abrasive cutting head, whereas only the water jet produced by the orifice is the acting cutting tool. Consequently, these are named pure waterjet cutting systems.

The PWJ cutting system have different cutting power depending on water orifice size. Actuating valve is included.

Nozzle filter

Increase nozzle lifespan with the inline filter system

The inline filter system us used to protect the orifice from particles in the water. Depending on circumstances particles can come from dirt that has entered the system, seals, mineral scale or metal chips from cutting and shaping the high-pressure tubing.

The inline seal can effectively catch particles and prevent them from impacting and potentially damaging the orifice edge. Such damages can cause premature failure of the orifice.

Filters are available as external units that fits our 3 axis machines.

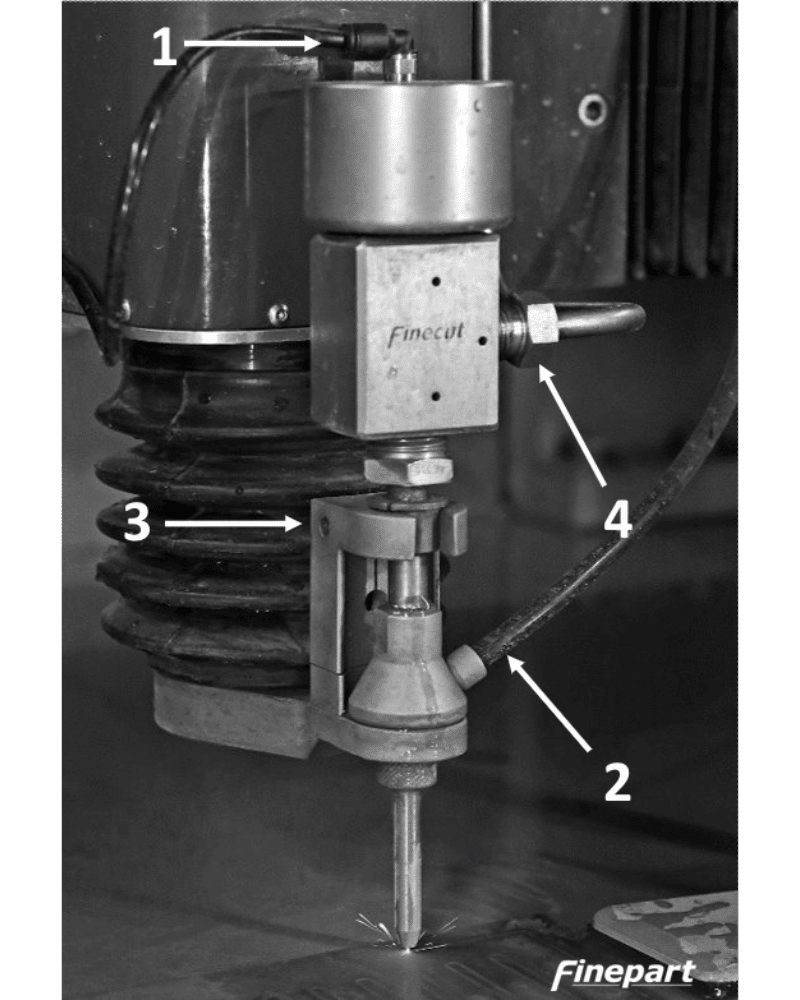

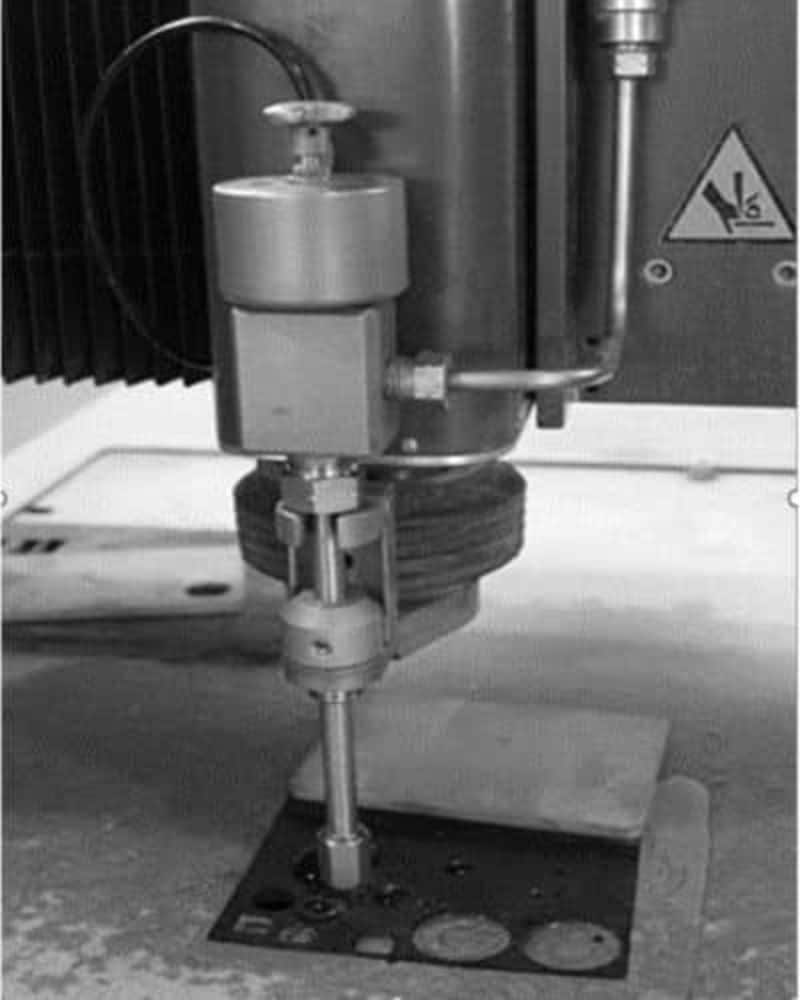

How to change cutting nozzle

Make sure the machine and pump is turned off and that there is neither pneumatic nor water pressure in the machine.

- Detach the pneumatic hose from the jet cylinder

- Detach the abrasive feed hose from the abrasive body

- Use allen screw to release the clamp holder on the nozzle tube

- Unscrew the nut completely and retract the high-pressure tube from the valve assembly.

- Lift the complete valve and cutting head assembly out of the machine.