Beyond cutting edge

Your world-leading provider of non-thermal precision cutting.

Enjoy ultra-accuracy for virtually all materials.

100% focus on micro abrasive waterjet process

In Finepart Sweden we love the waterjet technology and micro abrasive waterjet in specific. We have a deep knowledge that we are eager to share. Learn more about the benefits of the technology, what is micro abrasive waterjet and a lot more…

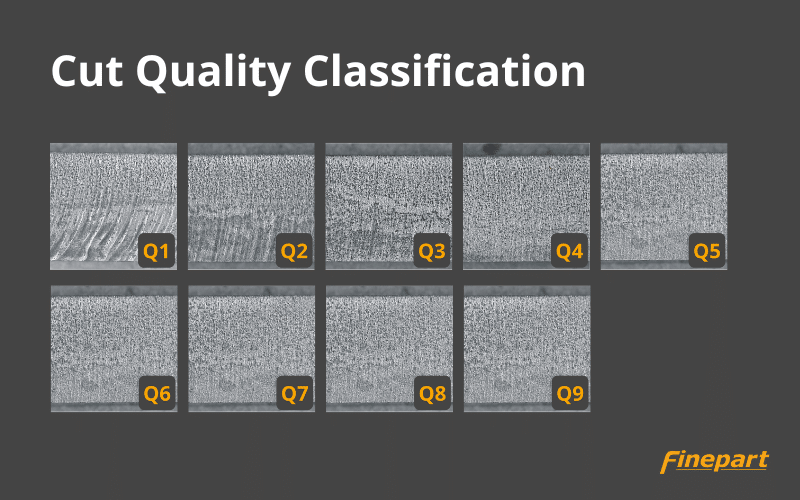

Flexible micro abrasive waterjet machining centers for accurate cutting

Discover our new generation of high-precision micro waterjet machines, which cut cold with no heat effect, meaning no material distortions. The conceptual machine tool design minimizes vibration and has a flexible fixturing system that enables various type of production solutions. The Finecut WMC500II is built by state-of-the-art components, to provide capability for your ultimate precision cutting. The small footprint and encapsulated design make it suitable for any type of workshop environment alongside other CNC machines and other sensitive equipment.