CASE

Fast cutting with the best precision in the world

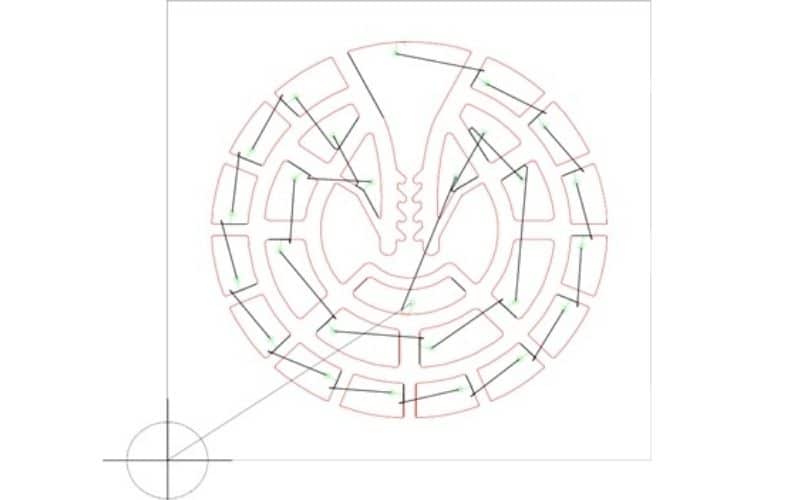

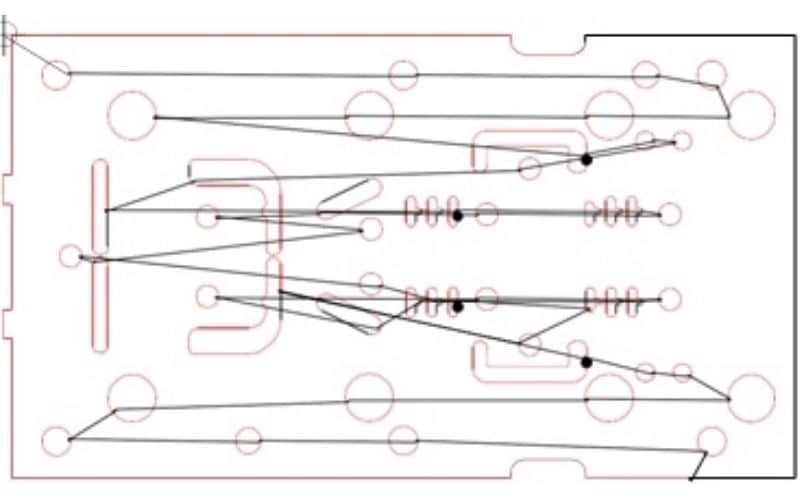

The micro abrasive waterjet produces fine surface quality. Reducing the speed results in a better surface finish and less taper on the cut edges. Any 3-axis machines can produce taper-free cuts. This is made through allowing the jet to erode material for a longer duration while following the contour, meaning that speeds must be reduced significantly.

5-axis allows higher speed

By adding 5 axis capability to adjust the approach angle of the jet, the taper in the cut can be compensated and speeds will not need to be reduced more than to meet an adequate surface quality. This means that cutting speeds can be increased by up to 150%. This means a significantly higher throughput in the machine. Return of investment will correspondingly come with advantages in both quality and productivity.

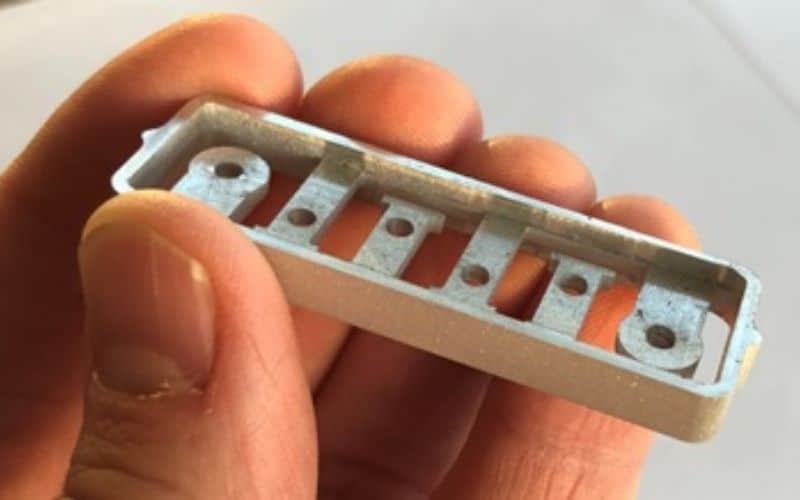

Precision

The Finecut machine is made for precision work and has a positional accuracy of ±2,5 µm. Parts can be cut with a tolerance of ±10 µm. With Finecut WMC500 5X, type ABX you can cut highly accurate parts with double speed. Learn more about the Finecut 5-axis machinery series