Precision 5-axis micro waterjet cutting machines offer a state-of-the-art solution for manufacturing intricate, high-precision components. This article will discuss the capabilities of 5-axis micro waterjet machines, diving into key topics such as the differences between 3-axis and 5-axis waterjet systems, and how to choose the best 5-axis micro waterjet for your needs.

VIDEO

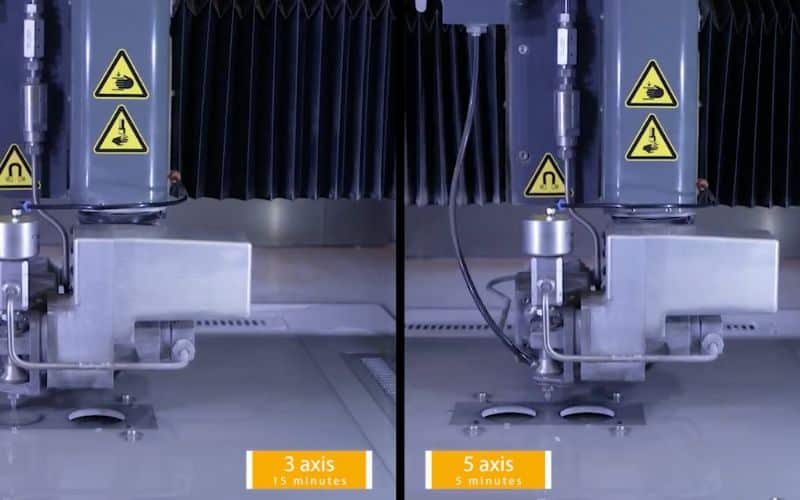

Precision cutting eyewear frames with Finecut 5 axis micro waterjet vs. 3 axis

What is 5-Axis Waterjet Cutting?

A 5-axis waterjet provides more advanced capability to operators by combining the benefits of traditional 3-axis waterjet technology with a sophisticated 5-axis motion system. By using five different axes of motion, these waterjets can reduce processing times and create more complex shapes.

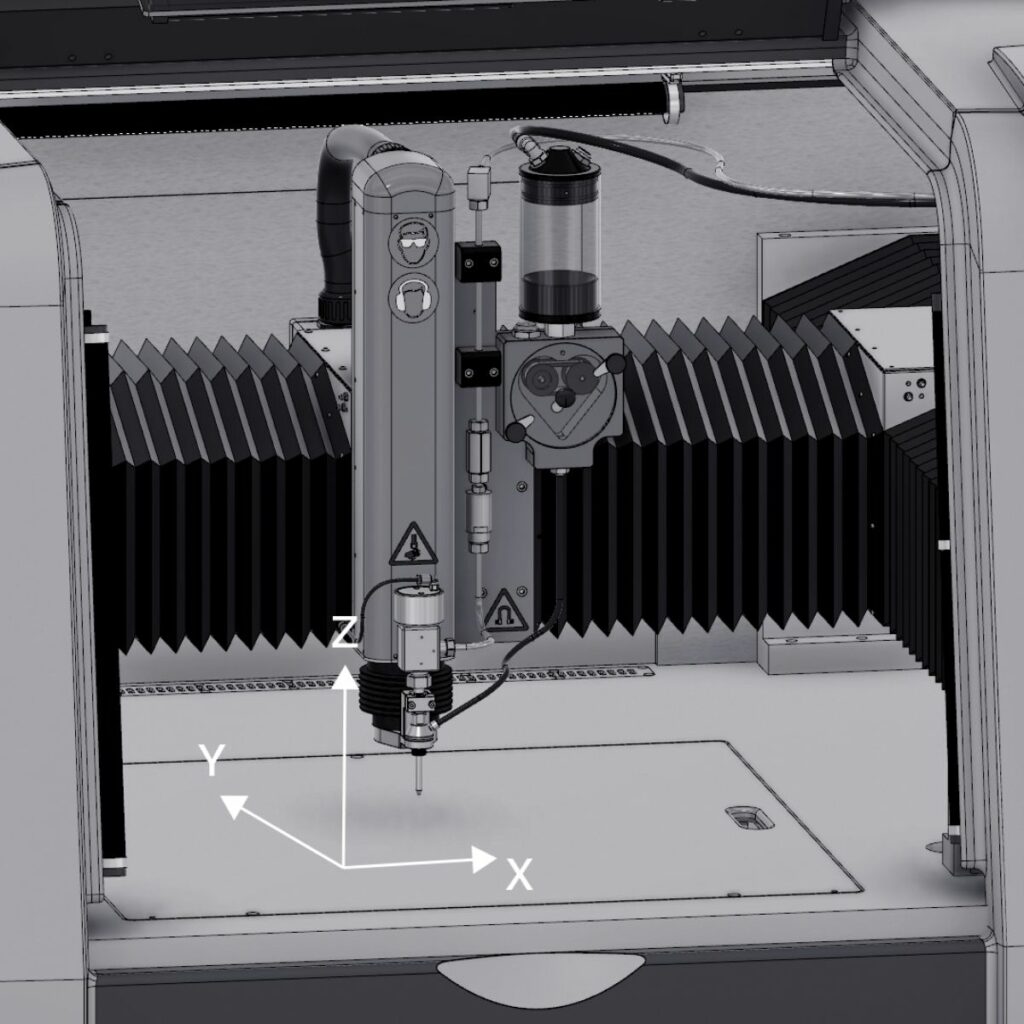

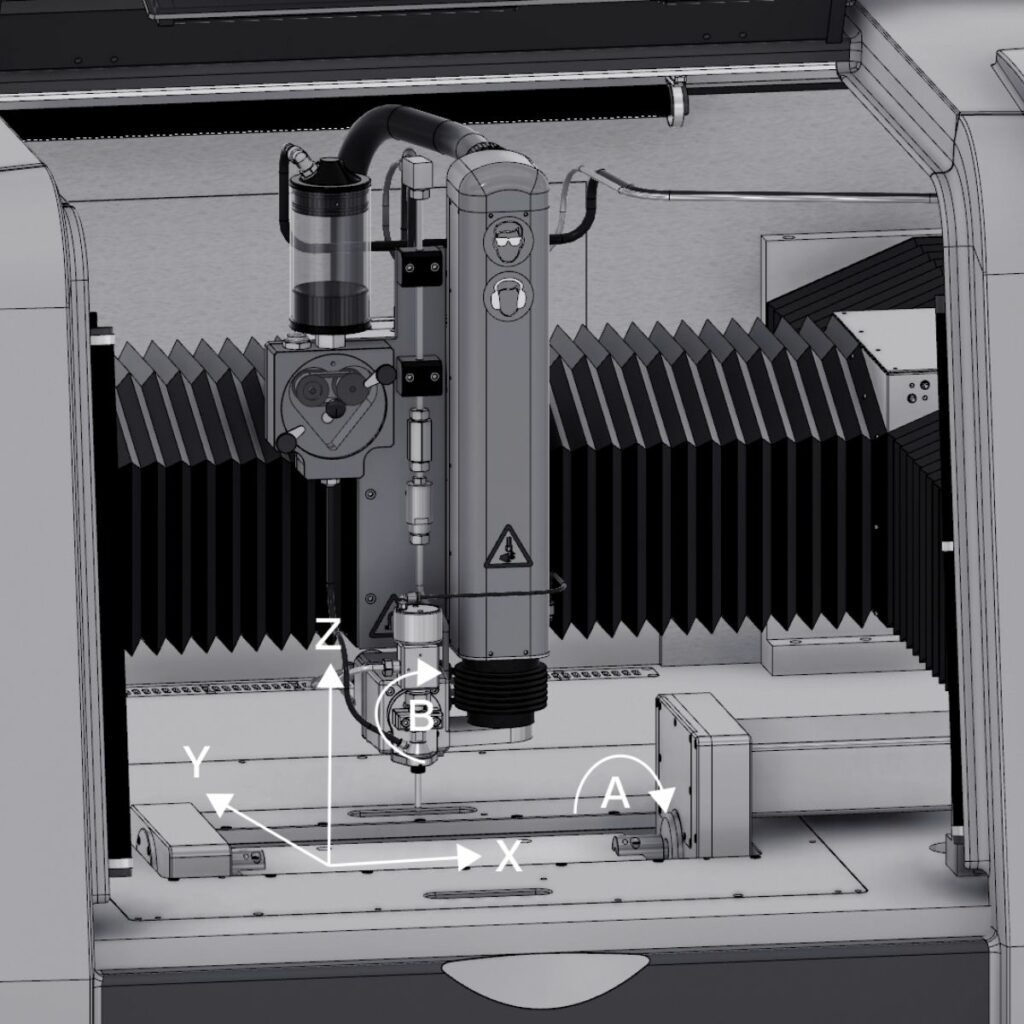

Three of these axes are for linear movement and are identical to those of 3-axis waterjet system. Depending on the equipment used, this could mean the movement of a carriage, worktable, or the cutting head, but standard 3-axis cutting and machining generally follow these guidelines relative to the operator’s perspective:

- X-axis: Left-or-right horizontal movement.

- Y-axis: Forward-or-backward horizontal movement.

- Z-axis: Up-or-down vertical movement.

However, the additional 4th and 5th axes in waterjet machines, often dubbed the A-axis and B-axis, introduce rotational movement. And similarly to the X, Y, and Z axes listed above, this can mean rotation of the cutting head or the part on the worktable. Relative to the operator, these axes work as follows:

- A-axis: Rotation around the X-axis, meaning a forward-or-backward pitch.

- B-axis: Rotation around the Y-axis, meaning a left-or-right roll.

The potential for simultaneous movement along these five axes is what makes it possible to cut complex, three-dimensional shapes with exceptional precision.

Advantages of 5-Axis Waterjet Cutting vs 3-Axis

The 3-axis micro abrasive waterjet machine offers great performance while cutting flat, two-dimensional shapes. However, a 5-axis waterjet machine provide several key benefits over their 3-axis counterparts:

Improved cutting versatility

A 3-axis waterjet cutting machine is excellent for cutting a variety of 2D shapes. It can perform vertical cuts in nearly any pattern on sheets of metal or other material. And with micro abrasive waterjet cutting technology, even 3-axis machines can cut highly intricate and precise patterns.

A 5-axis configuration however allows for simultaneous movement along additional axes, meaning the waterjet can cut more complex 3D shapes. Practically speaking, a 5-axis waterjet can create all the same shapes as a 3-axis waterjet with the additional capability of advanced cuts like helical and conical shapes, beveled curves, and objects like turbine blades.

Overall, 5-axis waterjet cutting machines provide valuable flexibility to product engineers if they need to create any three-dimensional shapes.

Faster cutting with taper control

With intelligent software, the Finecut 5-axis micro waterjet machine can increase cutting speed without causing unwanted kerf taper on part edges. This reduces processing times to improve efficiency even on simple 2D parts.

Normally, a given material and thickness will have an optimal cutting speed that eliminates kerf angle. Cutting too fast causes a V-taper, where insufficient material is removed from the bottom of the cut. Cutting too slowly causes reverse taper where excessive material is removed from the bottom of the material where the water jet widens.

By angling the cutting head correctly, operators can increase cutting speeds while still maintaining a perpendicular cut edge or some other cut angle if desired. It is worth noting however that this increased cutting speed has an impact on the surface roughness achieved during cutting.

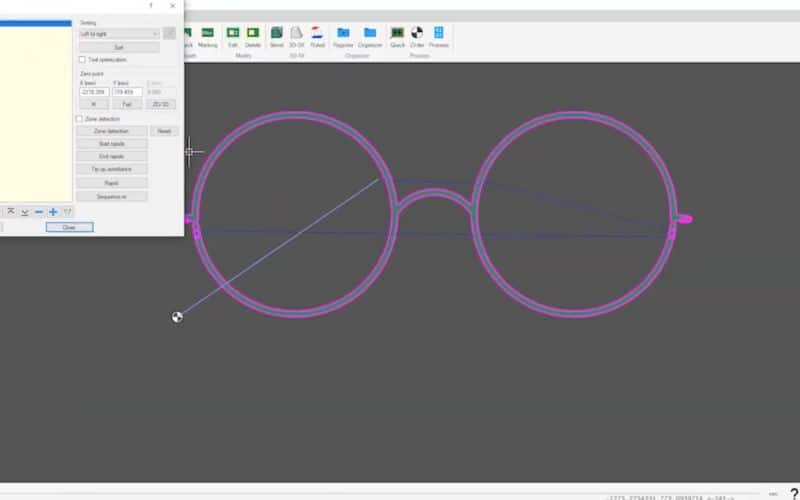

IGEMS CAD/CAM waterjet software facilitates the work in fine-tuning cutting angles to control taper for different materials, thicknesses, and cutting speeds. And while surface roughness is affected by cutting at faster speeds, the low roughness values achievable with Finecut series micro abrasive waterjets means product engineers have a lot of flexibility to adjust cutting parameters.

Efficient cutting for complex shaped parts

While 3-axis and 4-axis waterjets cannot perform certain curves and angles in a single setup, multi-sided parts can still be created from 3-axis machinery. For example, an object with holes cut into the top and through the sides can be completed in stages. Operators can cut the top holes, stop the waterjet, rotate and reposition the workpiece, find the correct datum point and alignment, through accurate fixture or onboard measuring devices, and then cut the side holes.

A 5-axis waterjet setup, however, can cut multiple sides and faces of the workpiece without the need to re-fixture and recalibrate the setup. This improves efficiency by reducing labor requirements, reducing processing times, and reducing the potential for errors during manual handling.

When is 5-axis the ideal choice?

Volume producers and R&D facilities should choose 5-axis capabilities for:

- Manufacturing components with 3D geometries or advanced shapes that cannot be achieved using 3-axis waterjet machines.

- Cutting of multi-faceted or multi-sided parts more efficiently.

- Improving shop versatility without the need for additional operations.

- Accelerating processing times during rush operations with lower requirements for surface finish.

- Cutting of really hard materials where taper angle control is needed to get rid of all taper

- Fine-tuning kerf angle on parts to improve quality.

A 3-axis waterjet may be sufficient when both:

- Cutting operations are limited to basic 2D shapes, and

- The increased flexibility of 5-axis capabilities is not worth the increase in equipment costs.

It should also be noted that not all 5-axis waterjets have the same capabilities. For example, the Finecut 5 axis micro waterjet Type ABX configuration of Finecuts series 5-axis waterjets has a fixed worktable with a 500 x 500 mm work area, and the cutting tool can rotate ±15° around the A and B axes. On the other, the Finecut 5 axis micro waterjet Type B4X configuration has a 360° rotating worktable with a cutting head that moves ±45° on the B-axis, but is limited in work space and is more suitabel for single piece production.

Which Is the Best 5-Axis Micro Waterjet Machine?

A Finepart 5-axis micro abrasive waterjet cutting machine offers the precision cutting, flexibility, and advanced control systems necessary to achieve high levels of accuracy and surface quality. It is ideal for cutting complex shapes into a wide range of materials. This allows operators to produce very high-value parts, like those used in medical devices, aerospace applications, performance automotive products, and luxury goods.

Product engineers and shop managers should evaluate 5-axis micro abrasive waterjets on the following parameters:

Fast cutting speeds

The example in the movie above shows that parts can be cut with 3 times higher cutting speed usign 5-axis taper angle control compared to 3-axis cutting. For high volume production, the pay off time can be shorter than 1 year.

There are many factors that affect cutting speed, including the reliability and quality of manufactured waterjet parts. Having a reliable high-pressure pump with a stable output, a high-quality focusing nozzle, and good-quality abrasives will all influence cutting speeds.

In addition to using premium components in our waterjets, Finepart can also use its advanced software to control taper and accelerate cutting processes.

3D cutting capabilities

Different waterjet models will have different limits on their range of motion and their work envelope. These equipment specifications will directly affect the size of parts and geometry of features that the waterjet can produce.

However, there is typically a tradeoff between the range of motion and work area size. To address this, Finepart produces 2 different 5-axis waterjet models, the 5 axis ABX and the 5 axis B4X, so that we can better address the needs of different fabricators.

Accuracy and precision

A micro abrasive waterjet offers significantly improved accuracy and finishing quality over standard waterjets. The highly focused water jet and fine abrasive particles give micro abrasive waterjets the ability to cut highly intricate designs. Finepart’s 5-axis waterjet machines can achieve tolerances of ±0.01 mm (±0.0004 in), making them an ideal choice for industries that rely on high precision for making advanced components.

Surface finish quality

High-quality micro abrasive waterjets produce excellent surface finishes. The cold-cutting waterjet machining process cuts a wide range of materials without forming burrs or microcracks around the cut. Finepart micro abrasive waterjets can even perform finished-quality cuts in a single pass.

Material compatibility

Choose a waterjet machine that is compatible with a wide range of materials, including metals, plastics, composites, and more. By having the option to cut numerous materials without compromising cutting capabilities, you can always select the best material for the application. The Finepart 5-axis waterjet machine offers designers the versatility to cut materials of any type.

Advanced waterjet software and hardware upgrade options

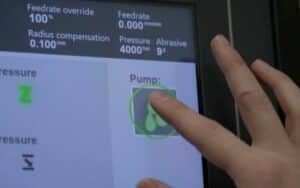

A 5-axis waterjet needs suitable software and CNC controllers to perform complex cuts with precision. The advanced Finecut machine HMI software means reliable cutting with high precision and excellent edge quality. Finepart also offers a range of upgrade options to meet your specific needs, including the option to upgrade your existing Finecut 3-axis waterjet to a 4-axis or 5-axis system.

Small footprint waterjet machine

Most machine shops, R&D facilities, and fabricators have a lot of equipment but very limited space available. Choosing a compact 5-axis micro abrasive waterjet cutting machine can boost throughput and unlock new capabilities in a relatively small package.

Finepart waterjet machines offer tight tolerances, non-thermal cutting, minimal kerf width, and impressive flexibility to supplement the needs of your shop. All Finecut series waterjets even offer single-pass finishing to improve efficiency and surface quality for a wide range of materials. And as a bonus, Finecut-series waterjets only occupy 2.75 square meters (30 square feet), with the option to place the high-pressure pump up to 100 meters (330 feet away)!

Integration and ease-of-use

Select a 5-axis waterjet cutting machine that is user-friendly and can be easily integrated into your existing production workflow. Finepart waterjets use intuitive software that requires minimal operator training, meaning they can be added to your shop without the need to hire specialized labor.

Technical support and after-sales service

Partner with a manufacturer that provides comprehensive technical support and after-sales service, ensuring a smooth transition and continued success in your precision manufacturing endeavors.

Improve Cutting Capabilities for Your Customers

The Finepart 5-axis micro abrasive waterjet cutting machine represents the cutting edge of high-precision manufacturing. With their ability to create intricate geometries, make complex cuts, achieve tight tolerances, and work with a wide range of materials, these machines give producers a competitive edge in their industry. Whether you provide custom waterjet cutting services to your customers or run a production facility, a Finecut series of micro abrasive waterjet is sure to be the perfect addition to your operation.

BEYOND CUTTING EDGE

Finecut Micro Waterjet Series

Easy to operate 3, 4, and 5 axis micro waterjet machines for high precision cutting stainless steel parts with ultimate edge and surface finish in one single process.