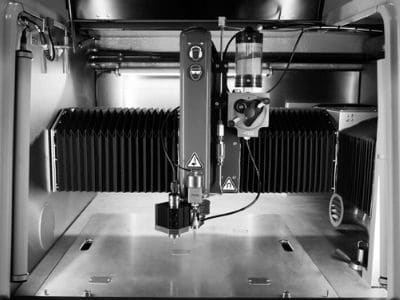

FINECUT WMC500II 4 Axis Type A micro abrasive waterjet

4-Axis Micro Waterjet Type A Machine Center

Finecut 4-Axis Waterjet Machine, a Micro Abrasive Waterjet, Beyond Cutting Edge.

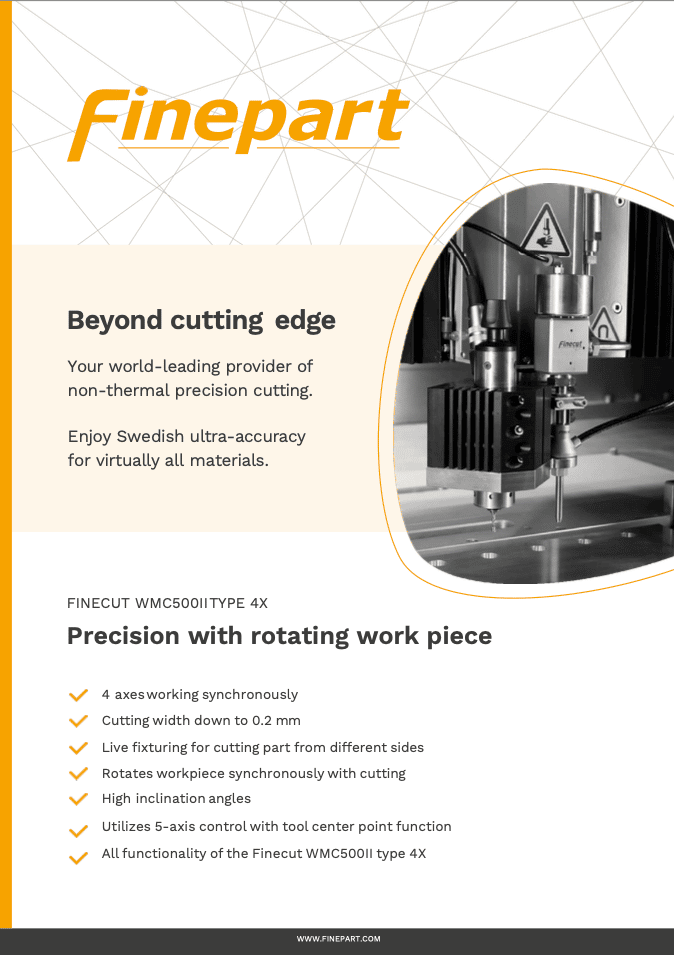

Precision with rotating work piece

- 4 axis working synchronously

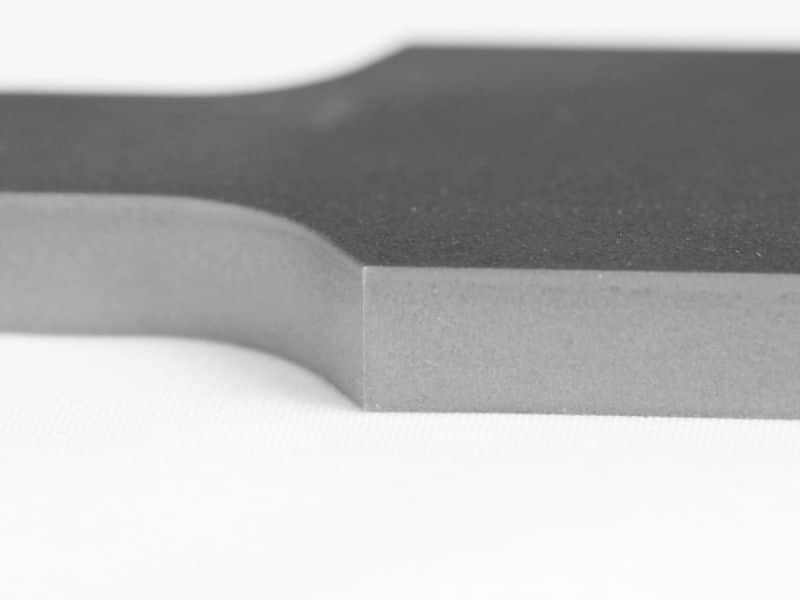

- Cutting width down to 0.2 mm

- Live fixturing for cutting part from different sides

- Rotates workpiece synchronously with cutting

- High inclination angles

- Utilizes 5-axis control with tool center point function

Finecut WMC500II 4 Axis Type A

Beyond Cutting Edge

Please add your contact details

We will email you the datasheet shortly

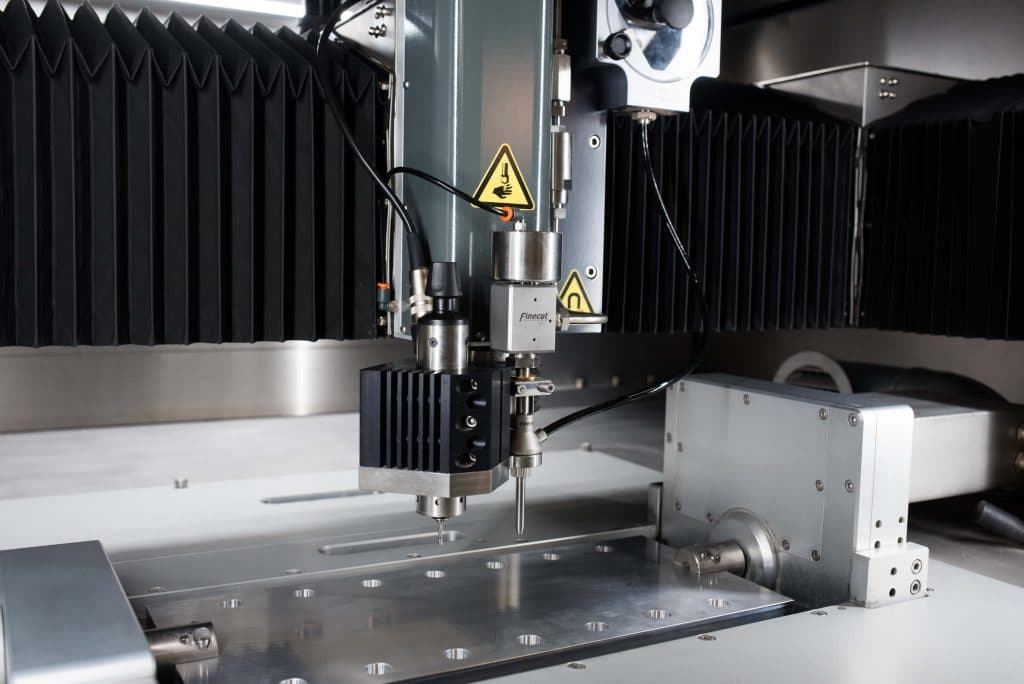

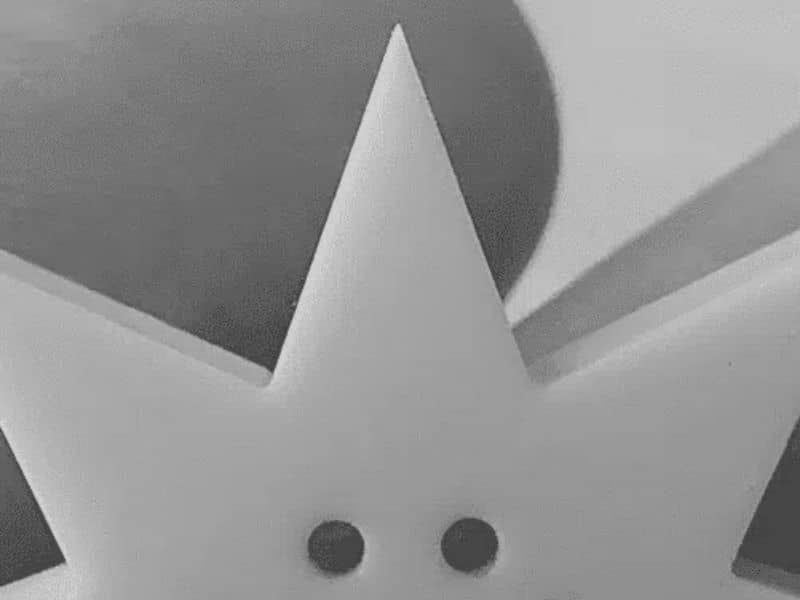

Cutting With 4 Axis Rotary Table

The A-axis can be fitted with a work table plate on which any work piece can be placed. With this mechanism the part can be reoriented to provide access for cutting from different sides of the part. This motion system setup allows the waterjet nozzle to cut along a contour, following the part’s 3D curvature, moving all four axis in synchronous motion.

Easy CAD/CAM Programming

The machine has a 5-axis waterjet controller with capability for tool center point programming. All these operations are easily programmed using the CAD/CAM software provided with all Finecut waterjet machines.

Finecut WMC500II – 4X

Cutting System Combining 3X cutting with rotating work piece

With our 5-axis motion system, the 3 axis cutting system is supplemented with a capability of turning the workpiece synchronously with the X-Y-Z axis motion of the tool. In our 4 axis waterjet machine a table-mounted A-axis is used to manipulate the work piece.

360 Degree Rotation Of The A-Axis

The rotating axis may be fitted with a chuck and be used as a rotary axis, which enables cutting helical geometries, rotational symmetries and contours in rotational parts (tube cutting). The A-axis can be fitted with a work table plate on which any work piece can be placed.

Detachable A-Axis

The machine has an optional probe with an easy user interface, that helps to set up and true up the table-mounted A-axis quickly. This enables combining the full versatility of filling the 500×500 mm work envelope with parts one day with 3-axis precision cutting, and then the next day producing highly complex 3D-shaped parts.

Can Be Fitted With Custom Fixturing

The A axis has one driven spindle and one support bearing. Both can be fitted with custom-made fixturing depending on the requirements of the machined part.

The Finecut 4-Axis Type A Waterjet Machining Center

To produce narrow tolerance parts, the micro abrasive waterjet cutting system is fitted with a very precise motion capability that accurately reproduces the programmed geometry. The WMC500II 4X, Type A has been designed to optimize the part precision and edge quality to a new and higher level of precision.

- Dynamic, high precision cutting head motion system, featuring linear motors and ultra-high resolution, thermally stable positional feedback

- Cutting table mechanically attached to the motion equipment for ultimate precision

- Rigidly built machine tool frame

- Easy set-up of machine fixtures for a wide variety of different applications with optional solutions including live fixturing with synchronous motion.

- CNC waterjet software and operators panel developed especially for abrasive waterjet cutting.

Technical information

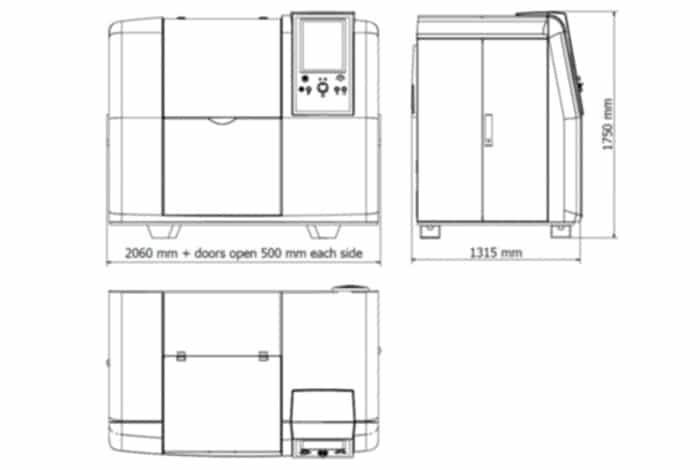

Finecut 4-Axis, Type A Waterjet Machining Center 500II, 4X Machine Size:2060L x 1315W x 1750H mm

Machine Size:

2060L x 1315W x 1750H mm

CNC Control:

Fanuc 31i-B5 and ALPHA Servo Drive with Nano Control

Motion system:

Linear motors and zero backlash reduction gears for precise motion

Absolute encoders:

Thermically stable Invar® linear encoders, 50 nm resolution

Motion Axis

- Linear servo motor drive on X-Y axis motion

- Precision ball screw servo drive on Z axis

- Linear servo motor drive on X-Y axis motion

- Precision ball screw servo drive on Z axis

- Positioning accuracy*: ± 2,5 µm

- Repeatability*: ± 2 µm

- Typical cutting tolerance ± 10 µm

- According to ISO 230-2

Cutting Speed

- Max cutting speed: 20 m/min

- Max traverse speed: 40 m/min

- Acceleration: 0.5g (X, Y axis)

Cutting System Option

- Fine Abrasive Waterjet: 0.2 mm, 0.3 mm.

- Abrasive Waterjet: 0.4 mm, 0.5 mm

Work Area

- Cutting envelope (X, Y, Z axis): 500 mm x 500 mm x 80 mm

- Fixturing area: 700 mm x 700 mm (max depth 700 mm)

- Cutting table size: 900 mm x 900 mm (W x D)

- Back door allows for inserting work pieces

Extra features for 4X

- Work envelope 500 x 500 mm for 3 axis cutting

- Work envelope ca 370 x 200 mm between centers in A-axis fixure depending on fixturing

- ±360º tilting capability on A axis, A axis can be removed when not required

- Possibility to set up safe zones to prevent collision

Speak With A Waterjet Specialist

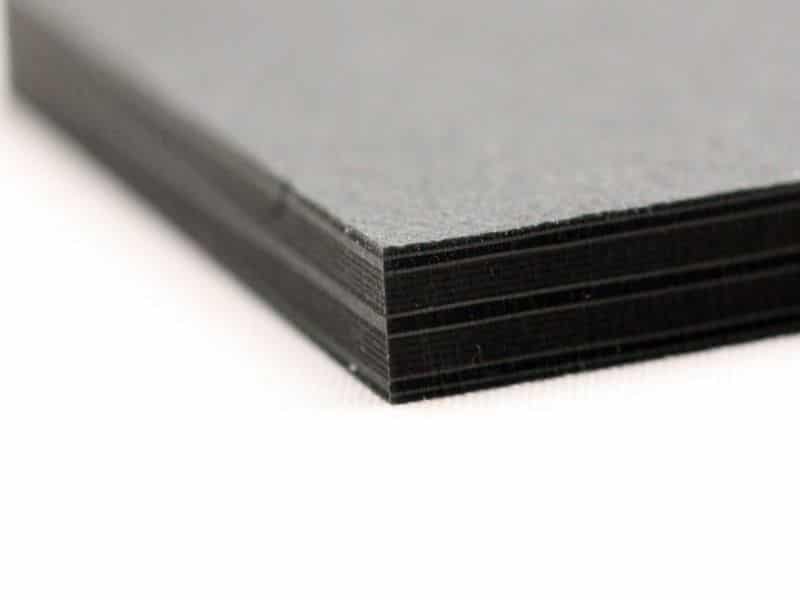

Three Types Of Cutting Systems

Depending on material, part complexity and level of miniaturization, our precision cutting can be made with any of our micro waterjet machines that are available in 3 different categories:

- Fine / Micro abrasive waterjet

- Conventional abrasive waterjet

- Pure waterjet

A range of sizes from 0.2 mm to 0.76 mm is available, whereas the larger jet facilitates a greater cutting power.

Flexible Fixturing

3D part geometry can be cut with assisting additional servo axis that manipulates the part synchronously to the cutting motion in order to provide access for the cutting jet.

A variety of innovative fixturing solutions can be adopted depending on the part requirements.

It is also easy to make your own fixtures, using the machine’s palletized fixturing solutions.

For repeat orders, this solution enables you to quickly set up and produce.

Advanced Waterjet Options

The Finecut can be equipped with several options like:

- Measuring probe

- 5-axis cutting head

- Turning axis

- Drilling unit

- Vision system

- and more

We also develop new options that serve the customer’s needs for efficient production. All options are retrofittable to existing machines.

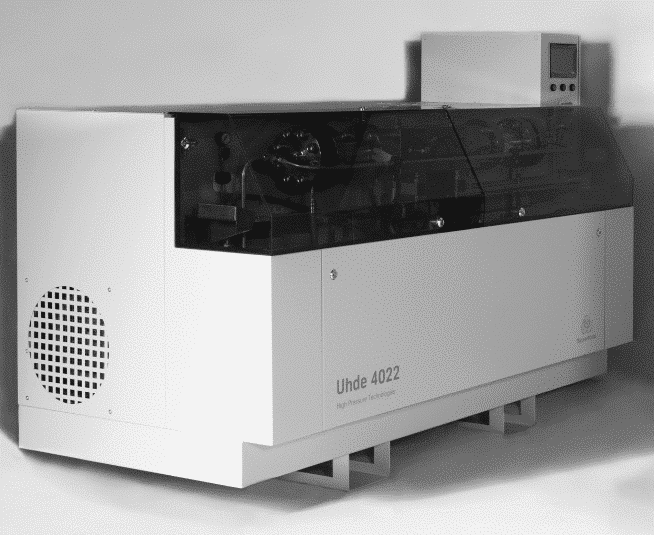

Ultra-High Pressure Water Pump

The cutting process is powered by an ultra high pressure pump. Compressed water is supplied from the pump to the Finecut machine through high-pressure hard tubing.

If needed, the pump can be placed away from the machine, in another room, or on another floor.

Pump functionality including water pressure settings are controlled via the Finecut CNC control panel.

A Precision Cutting Machine For Any Workshop

The Finecut machine is a compact fully integrated high-precision 4 axis waterjet machine center.

- Compact footprint so it is easy and convenient to place in your workshop.

- Fully encapsulated design keeps water and grit in the machine, so it can operate alongside your other CNC machines.

Materials That Can Be Cut With Finecut 4-Axis Waterjet System

The Finecut™ WMC 500II 4-Axis waterjet machine is a highly dynamic and fully encapsulated motion system 4 axis cnc waterjet cutting machine that can cut virtually any material with a width down to 0.2 mm.

Get a test cut & discover our great precision

Always with Finecut

Flexible Fixturing For Any Application

several solutions for different applications and requirements

State Of The Art Machine Components

latest technology for high dynamic capacity and accuracy

Additional Functions & Practical Solutions

great assisting tech for improved automation, setup and handling

High-end support from reliable partners

high pressure technologies for enhanced precision and control

User-friendly panel with Finesoft

easy to use interface for software & operators panel

Retrofittable developments

always gain from the latest technology and innovations