Options

Fixturing & Work Piece Holding

Quick set-up for cutting parts

Vaccum fixturing for complex cutting

Non-destructive work piece holding

Options No. 6001700

Fixture plate, standard

Standard aluminum work piece holding

Plate size: 740 x 740 mm

As standard fixture a flat aluminium pallet sized 740 x 740 mm is fitted into a seat in the machine table. With this plate a wide variety of customized fixturing solution can be made. Guiding pins in the machine table ensure accurate re-fitting of the fixture plate for returning jobs.

The fixture plate can be delivered in a version featuring stainless steel precision guide pin hole inserts for cases where a fixture is to be used and re-fitted often for extended time.

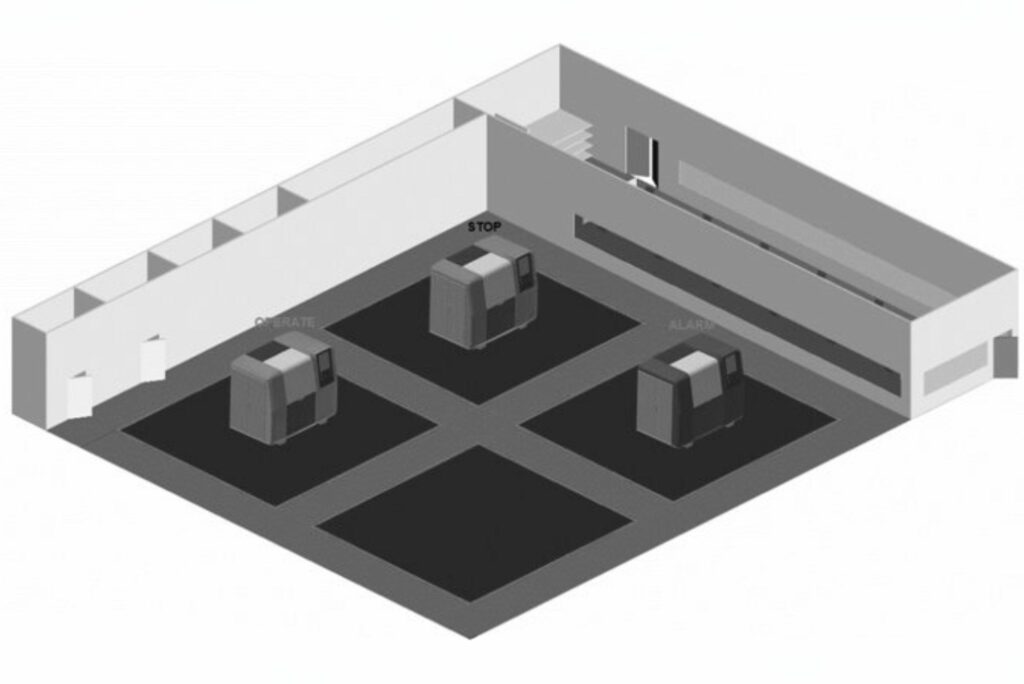

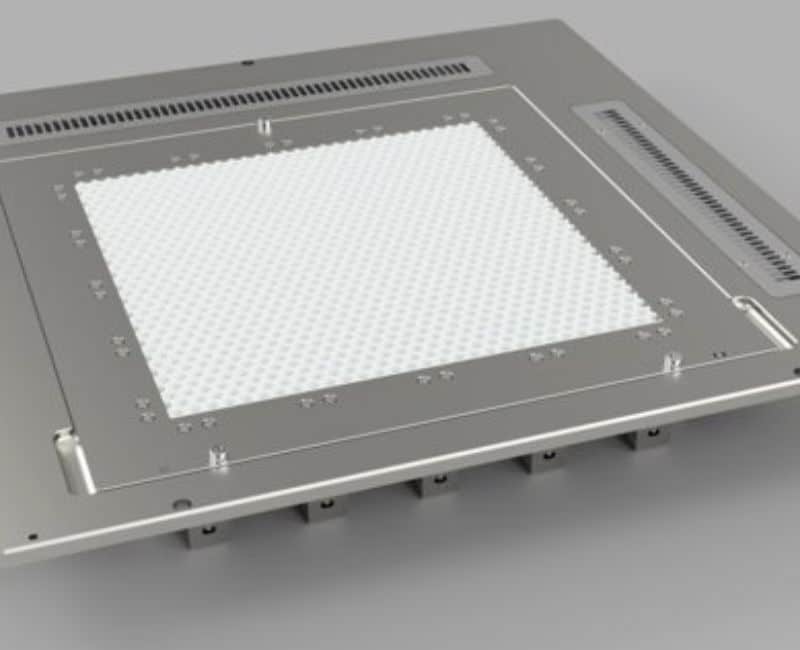

Options No. 6001750

Replaceable insert plate

Replaceable insert plate work piece holding

The work holding system in any of the Finecut micro waterjet machines features an insert plate that can be used to simplify light fixture handling and reduce cost for aluminium pallets.

The 6 mm aluminum plate has guide pins for accurate relocation of fixtures. It is adopted to the 500×500 mm workspace. The smaller size and lower weight make it simple and less costly to replace and easy to build fixtures on.

The guide plate holding the inserts features openings to allow excess water and abrasive to be swept into the catcher tank.

Options No. 6001900

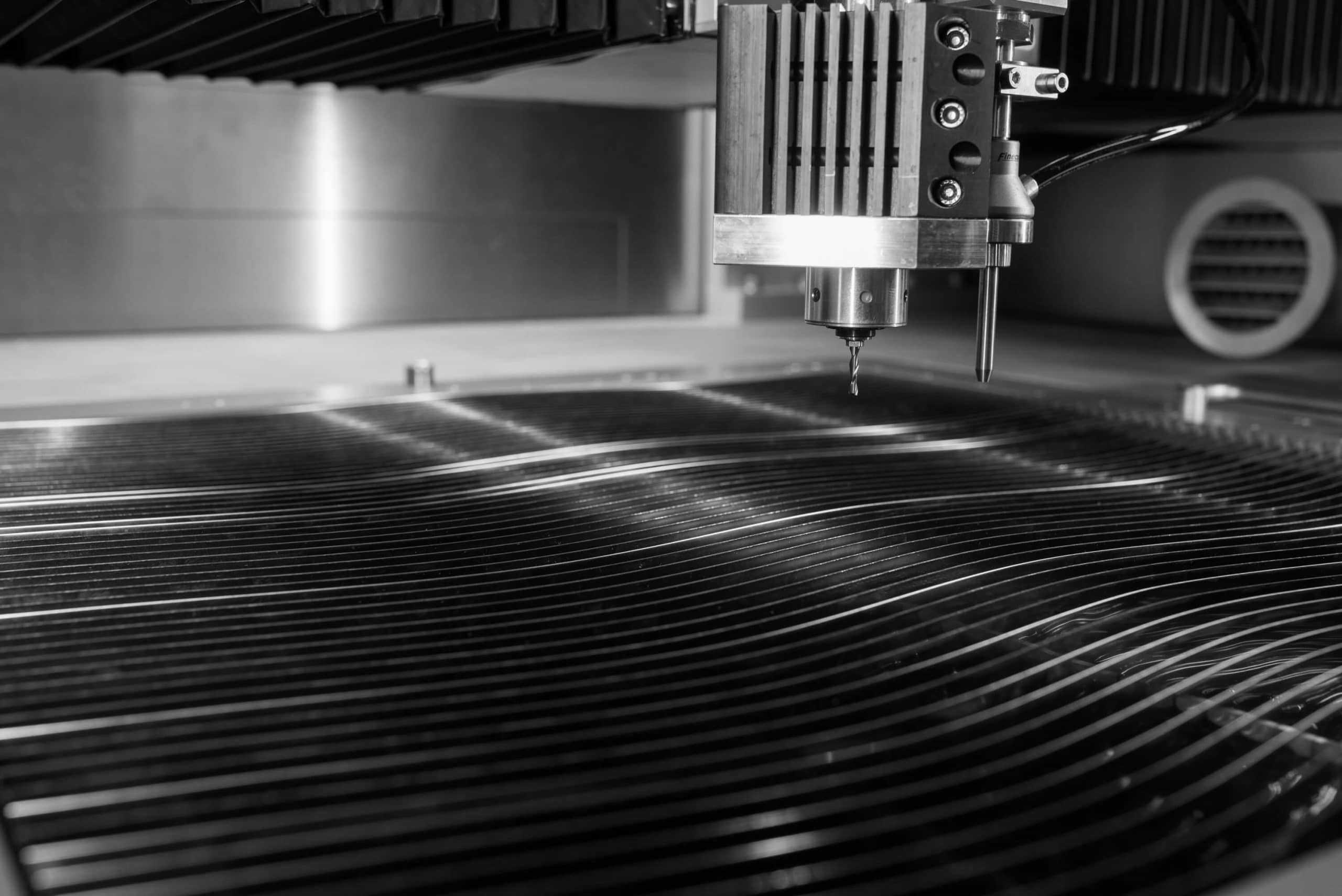

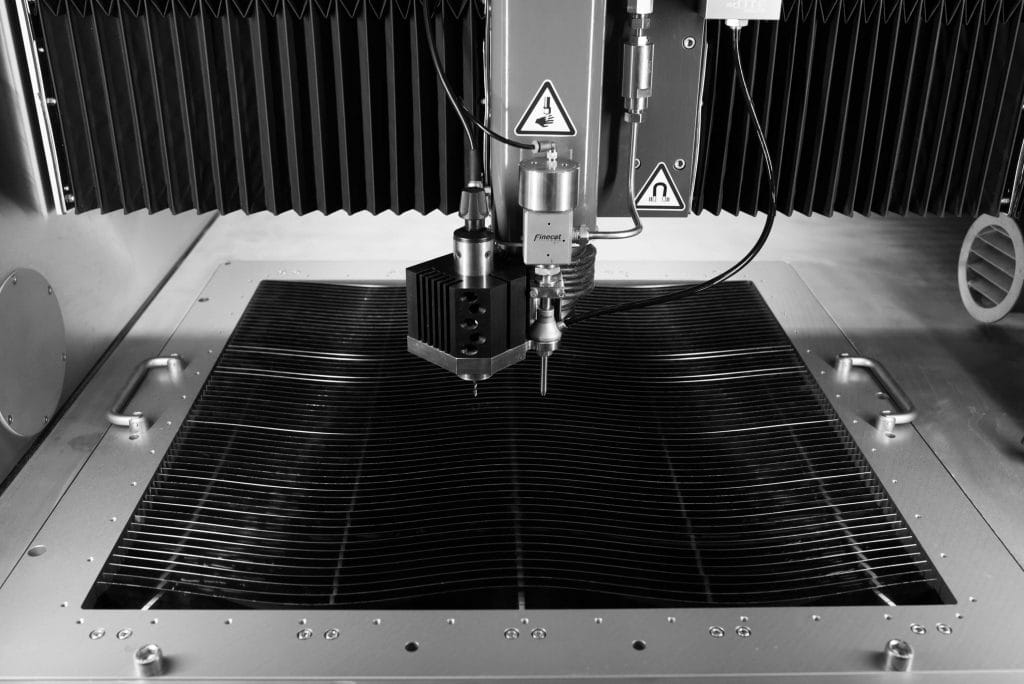

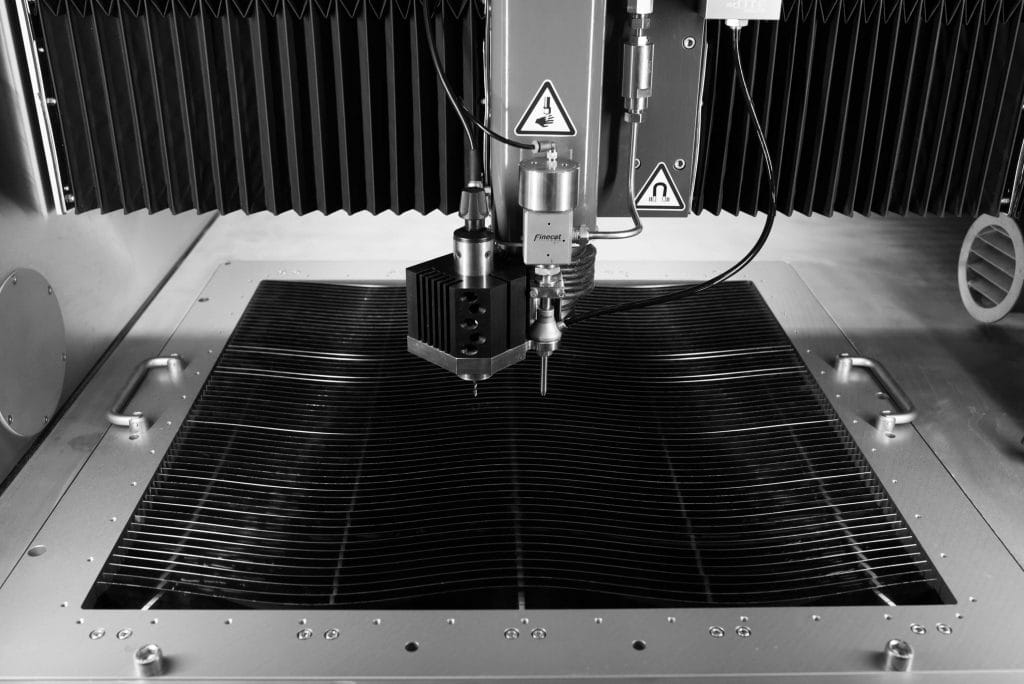

Wave grid

Multi-purpose non-destructive work piece holder

Wave grid holder is a multi-purpose work table solution.

Use this to place and material and quickly cut a part from it. The wave grid uses exchangeable wave formed deep and thin slats that support the work piece.

With wave formed slats the risk of cutting along a slat is minimized. As the slats wear they are exchanged for new ones.

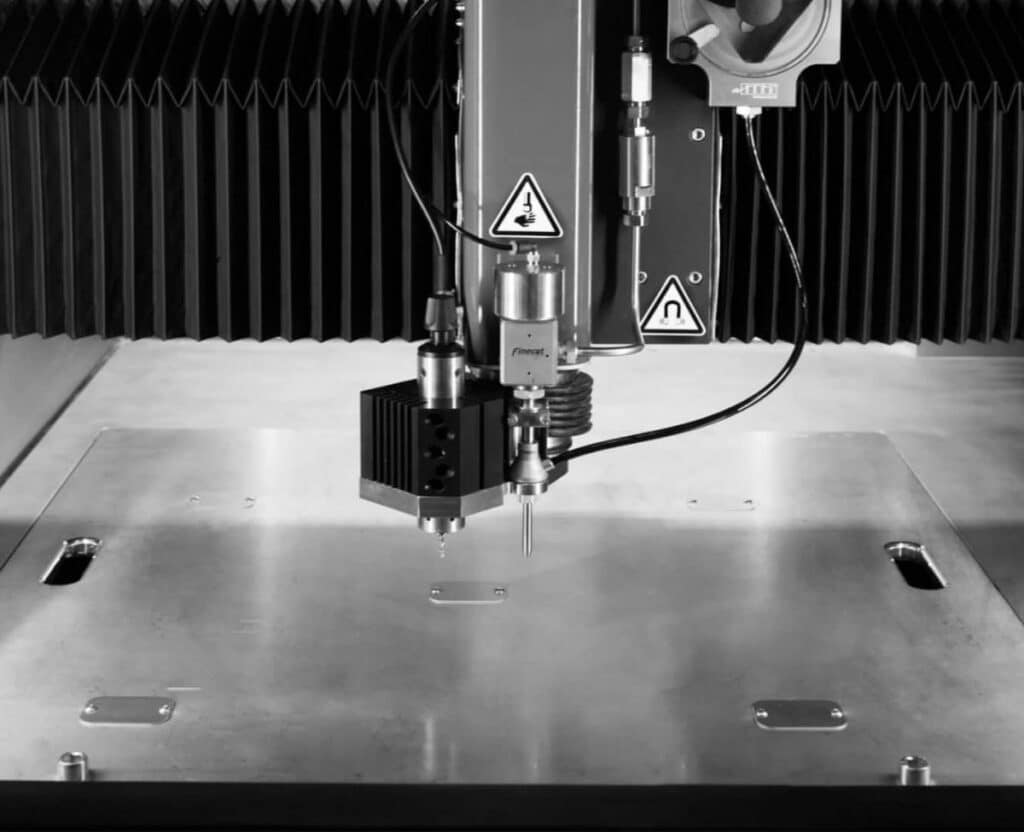

Options No. 6001950

Rhino grid

Non-destructive work piece holding

The non-destructive work holder is a multi-purpose worktable solution. This may be used to place and material and quickly cut out a complete part from it, without having the part falling through the fixture.

The Rhino grid utilizes Rhino board, that rests on support and prevents jet rebound effects which can affect the bottom surface of the cut part.

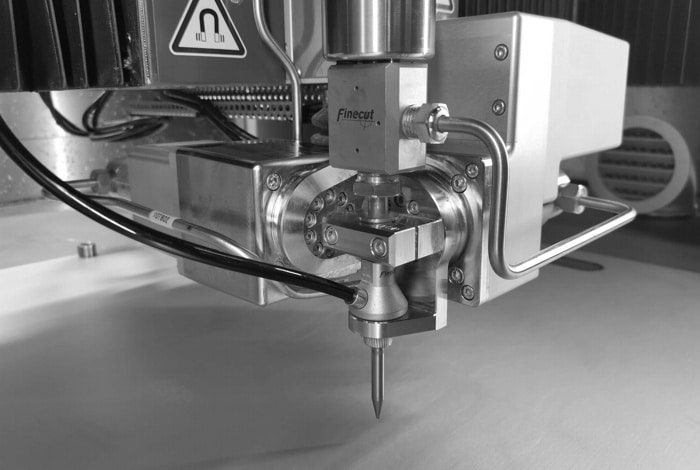

Options No. Custom Solution

Vacuum fixture system

Custom work piece holder for complex cutting

Finepart supplies integrated vacuum fixture systems for production purposes. The includes vacuum pump, water traps, Part clamping devices, etc.

Vacuum fixtures are typically custom made for each product case. Finepart supports customer with custom solutions for series production. With the vacuum system installed in any of the Finecut micro waterjet machines, new product related fixture parts can be produced on the Finecut machine.

For cutting complete contours the part needs to be held by its center, avoiding clamps around the edges. To enable this the parts may be held by vacuum. The part rests on an island supported at a depth where the cutting jet lost most of its energy to prevent cutting into the fixture.

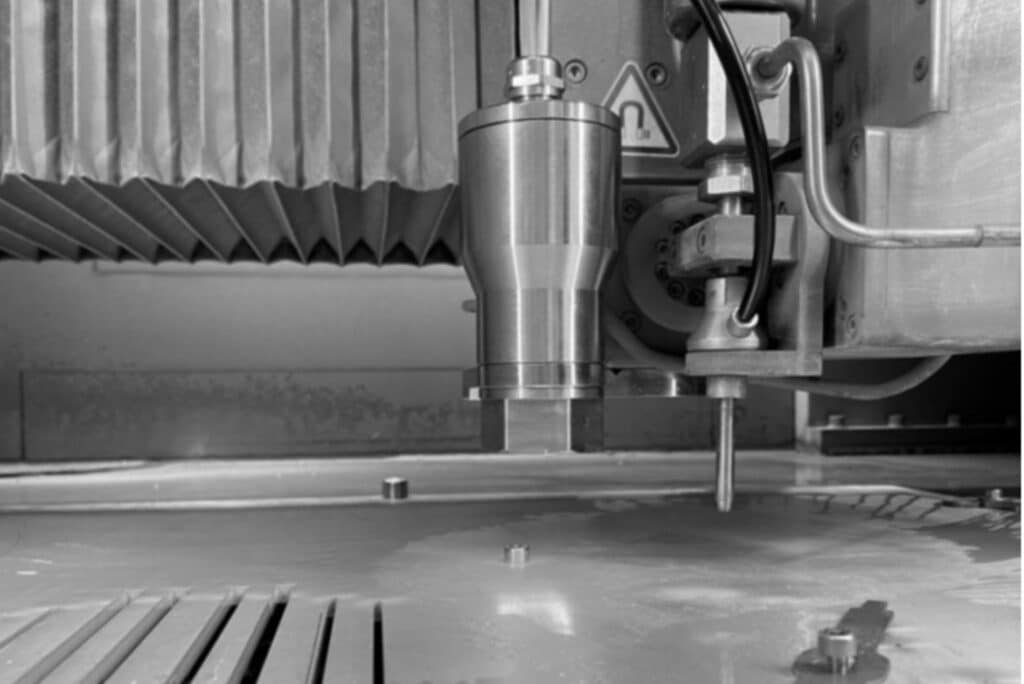

Options No. 6005100

Dry-catcher

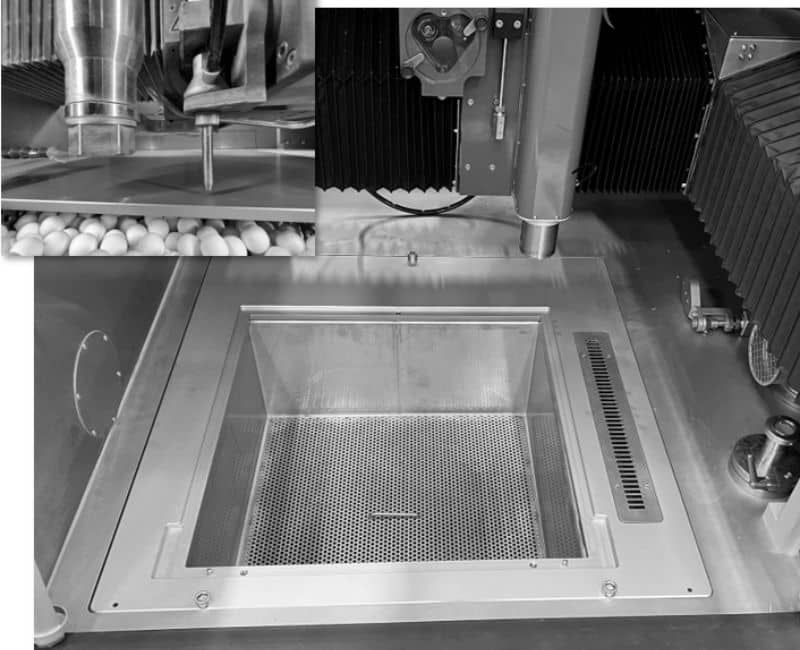

The dry catcher utilises a modified catcher tank with dry-catcher insert.

- Ceramic media basket beneath the fixture plate

- 6 mm thick fixture plate insert (used to enable quick changes of fixtures)

- video system for measuring, location and alignment of cut paths (placed at an offset to the cutting head).

An optional surfactant dispenser can spray the top with protective media to avoid any contamination. The surfactant is collected in a separate drain.

Options No. 6005100

Surfactant spray

Stain and dirt removal, singulation of optics, electronics, etc.

When part need to be free from stains and dirt a spray can wash away stray abrasive and cutting debris. This helps to ensure part cleanliness and prevents particles sticking to the surface as parts come dry.

An optional surfactant dispenser can be used to spray the top with the protective media to avoid any contamination. If this feature is combined with the dry-catcher media is collected in a separate drain to enable recycling.