Machine Pressure Monitoring

Optional signal tower that lights up when actual machine pressure deviates from the settings. The Alarm signal is visible in the machine HMI panel and alarm light, visible across the workshop.

Options No. 6002800

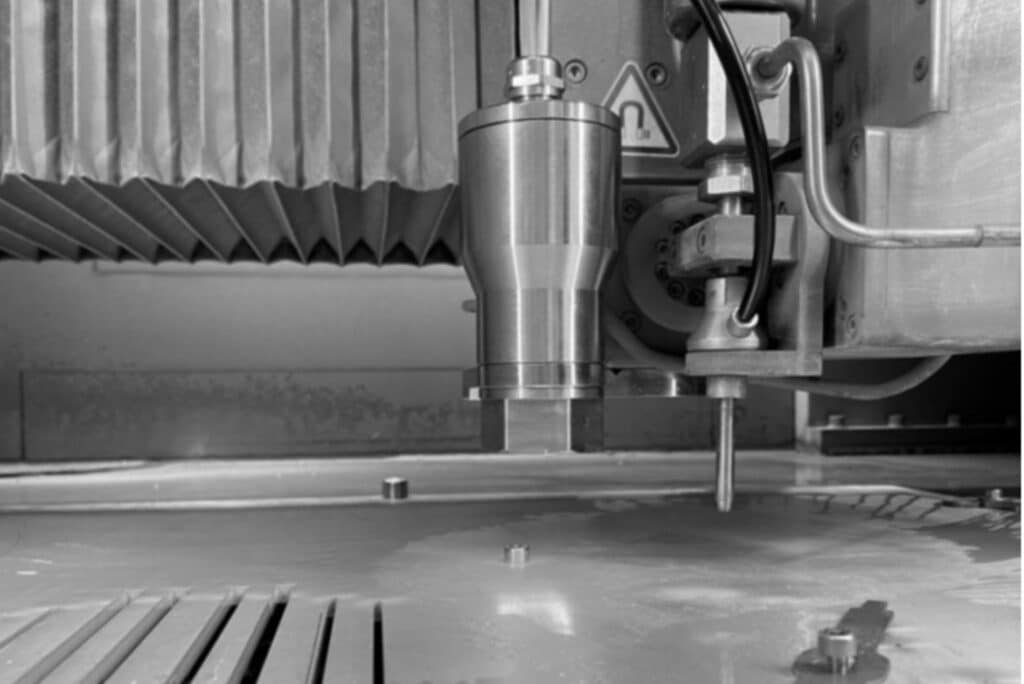

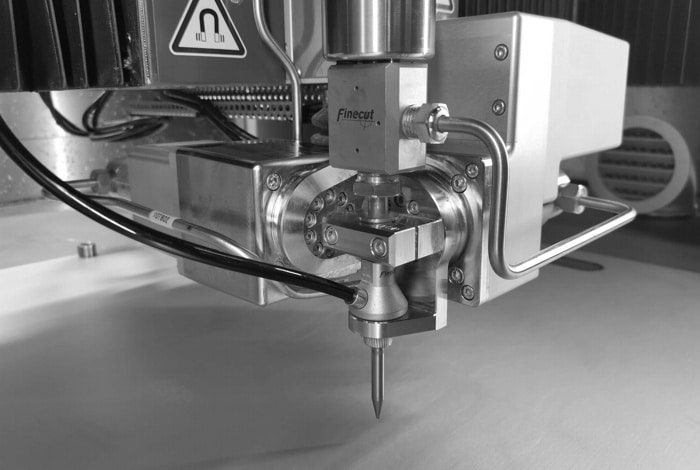

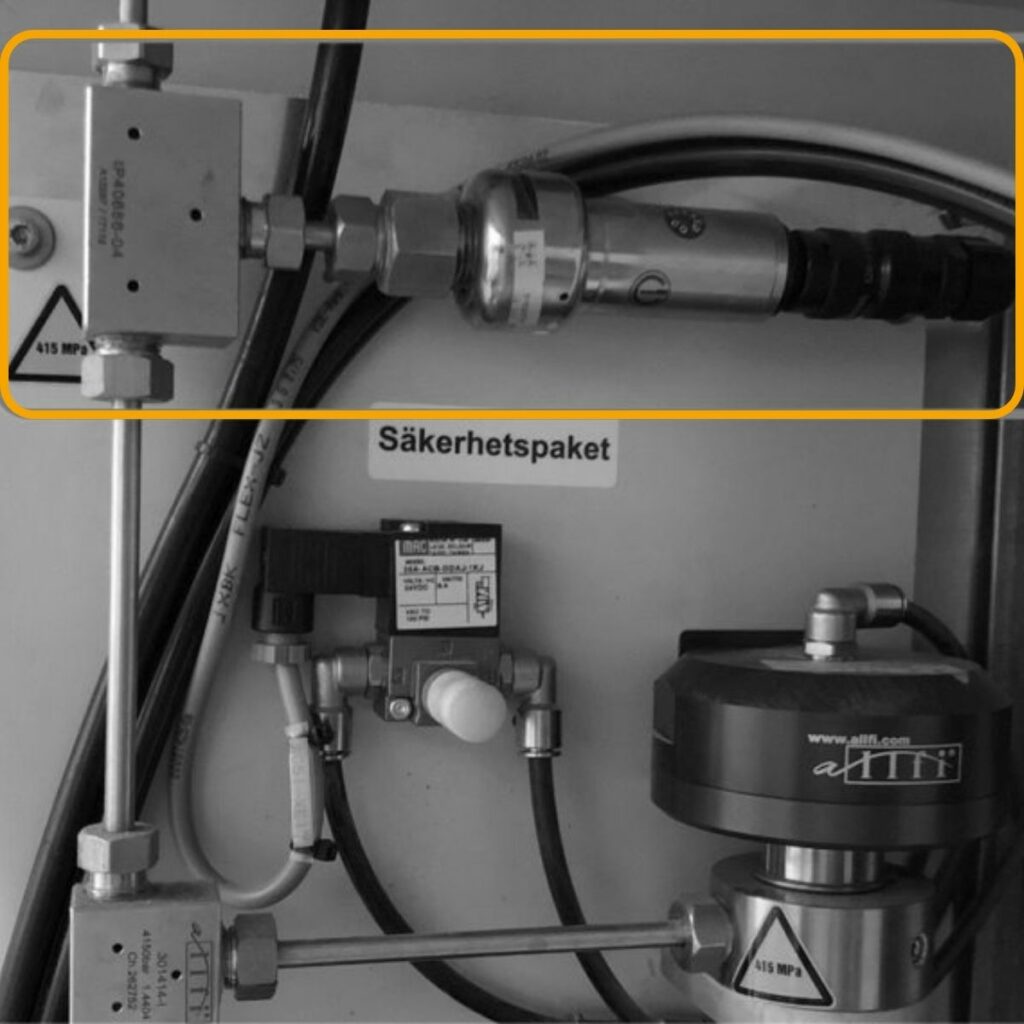

Machine pressure sensor

Signal in the HMI panel to let your know your actual pressure levels at the nozzle, rather than at the pump.

A high-pressure sensor placed in the high pressure line just before entering the machine workspace ensures that you know your actual pressure levels at the nozzle rather than at the pump.

The sensor reading is integrated in the control system and is presented in the Finesoft HMI.

Especially when you have a long distance between pump and machine, or if you have several Finecut waterjet machines at different distances from the high-pressure pump, this option allows you to optimize your cutting parameters for most efficient and economic operation.

Options No. 6002900

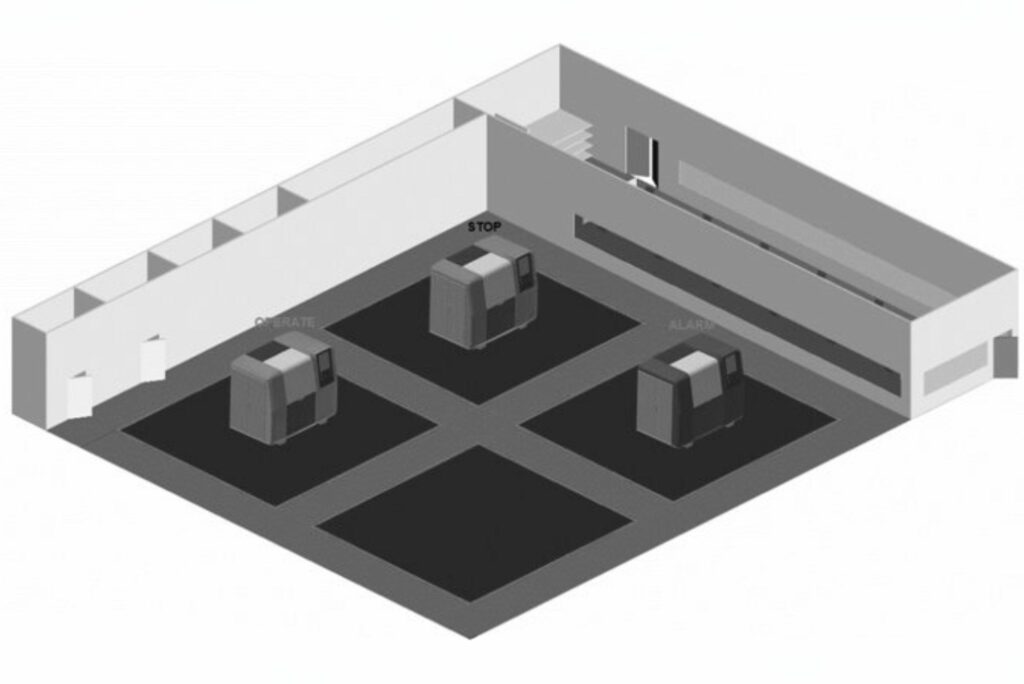

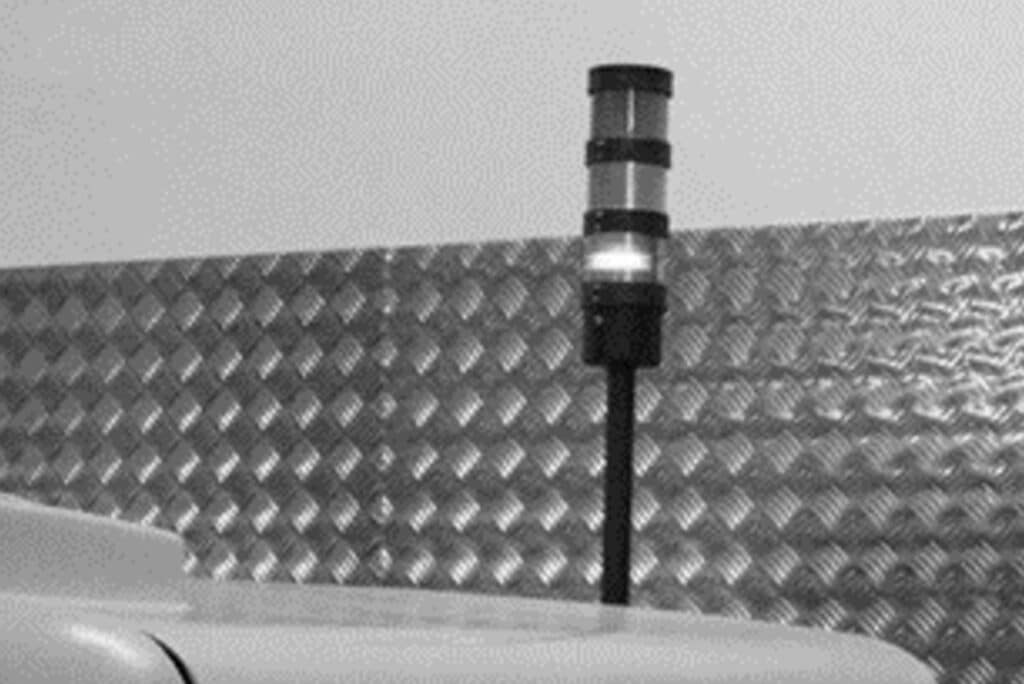

Exterior signal tower

Signal tower indicates of any machine status deviates from defined settings that impacts the cut quality.

The Finecut machine has indication of messages and alarms on the HMI panel, but the signal tower is visible far away from the Finecut machine and warns that action is needed.

The external light tower will show the following:

- A flashing red light if the front door is open.

- A solid red light is an alarm has occurred.

- A solid green light if a cycle is running.

- A solid orange light if the cycle is in hold.

Suitable if you have few operators to cover a big work area. To increase visibility a light tower can be used to visually indicate machine status from a distance in the work shop. Light tower feature green, yellow and red light signals from the controller. Mounts on machine top cover.