BEYOND CUTTING EDGE

Vulkam has selected the Finecut WMC500II 5X for its industrial breakthrough in machining amorphous metals.

Vulkam, a cutting-edge deep-tech company based near Grenoble, France is a future world leader in metallurgy and is leading the way in the industrialization of amorphous metallic alloys—also known as metallic glasses.

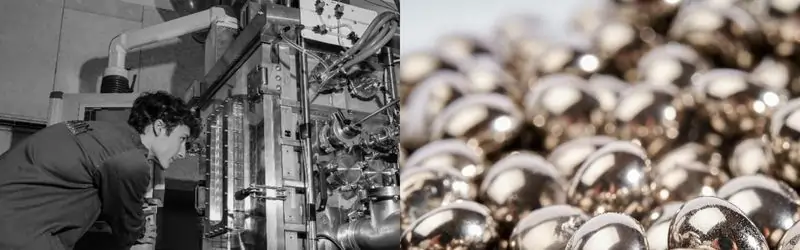

These high-performance materials offer exceptional strength, elasticity, and corrosion resistance, making them perfect for advanced micro-components or micromechanical parts in medical, watchmaking, luxury, aerospace and precision engineering applications.

With 30+ years of academic research from the SIMAP metallurgy lab at its foundation, the Vulkalloys, the Vulkam range of metals with its extraordinary properties, will set a future standard in metallurgy and metal processing.

Industrialization is on track, but at the same time, efficient manufacturing parts from amorphous metals presents major challenges—including machining.

The Challenge of Machining amorphous metal alloys

In the first half of 2024, Vulkam has invested a lot in its machinery, such as in a Finecut WMC500II 5X, type ABX, a system from Finepart Sweden AB, to address some of these challenges.

Indeed, the Finecut system offers what traditional technologies can’t: ultra-precise and cold cutting without compromising material integrity.

“With their high properties, amorphous metals require adapted machining techniques. We needed a high-performance solution offering micron-level precision and total flexibility in cutting shapes”. says Mr Xavier Cerutti, Technical Director at Vulkam.

“Finecut proved to be a game-changer for us.”

Mr Sebastien Gravier, CEO and co-founder at Vulkam.

From Research to Scalable Production

The Finecut WMC500II 5X is now an integral part of Vulkam’s development and production process, enabling complex prototyping and precision manufacturing with outstanding repeatability.

“The installation was fast, and our team quickly gained confidence thanks to Finepart’s training and support,” Mr. Cerutti adds. “We are now able to efficiently produce components with complex geometries, clean edges, and without altering our materials.”

Mr Sebastien Gravier, CEO and co-founder at Vulkam.

A Partnership Built on Innovation

The cooperation between Vulkam and Finepart reflects a shared commitment to engineering excellence and next-generation manufacturing.

“Vulkam’s innovation in material science is truly unique. We’re proud to support their mission by providing cutting technology that meets the uncompromising demands of amorphous metal machining.”

Lars Darvall, CEO of Finepart

About Vulkam

Founded in 2017 and located near Grenoble, France, Vulkam industrializes amorphous metal alloys (metallic glasses) developed over three decades of research. The 40-person-company serves high added-value industries with extreme requirements for precision, performance, and miniaturization.

About Finepart

Finepart Sweden AB develops and manufactures micro abrasive waterjet systems under the Finecut brand. Founded in 2012, the company serves global customers seeking non-thermal, ultra-precise cutting solutions. Finepart is listed on Spotlight Stock Market in Stockholm and operates from Bollebygd, Sweden.