Learn how we solved cases for other clients

What better way to discover what’s possible than to learn from our other customers’ experiences? Here you can explore a range of cases that show how different companies in different branches successfully have achieved their goals through our micro waterjet cutting.

CASE: LBY TECH AB

CASE LBY Tech AB ”A great complement to the existing W-EDM” To succeed, long-term collaborations…

CASE: BROGREN INDUSTRIES

CASE Brogren Industries Productivity, quality and development. These are the key words for Brogren Industries,…

CASE: BONE GRAFTING SYSTEM

CASE Cutting of surgical implants Today, more and more people have a hip prosthesis, which…

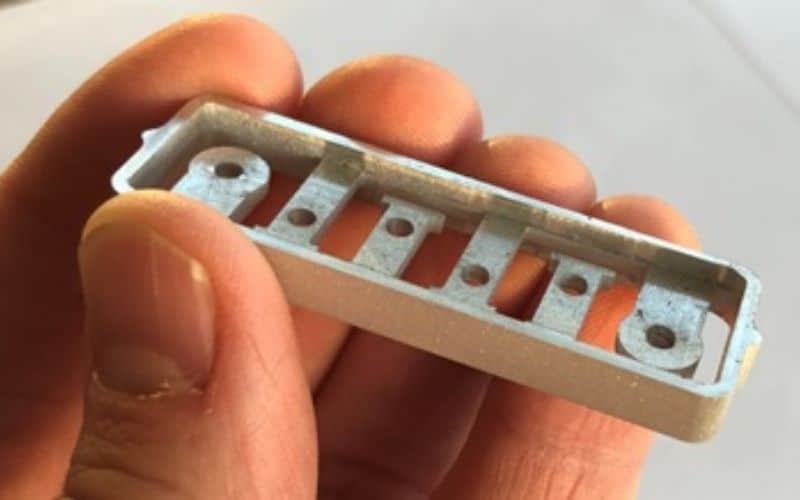

CASE: SHIMS 1 MM

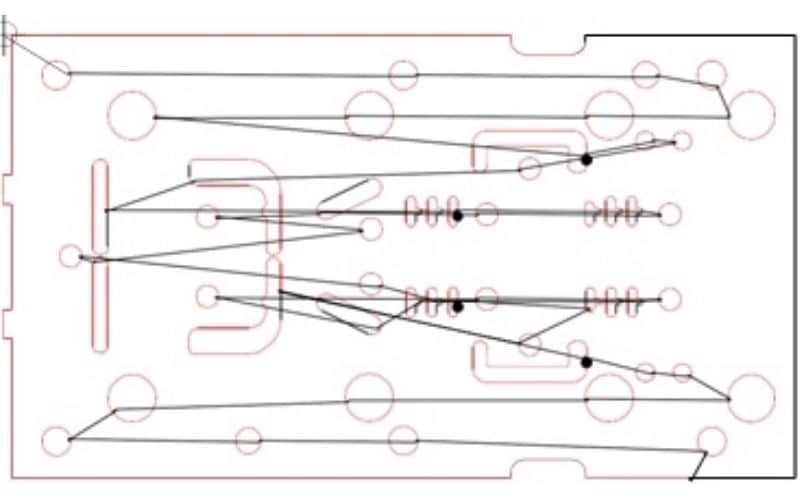

CASE Comparison of W-EDM & Finecut FAW300 In this case we have compared the Finecut…

CASE: W-EDM vs FINECUT FAW300

CASE W-EDM vs. Finecut FAW300 The Finecut process is a suitable complement to Wire EDM….

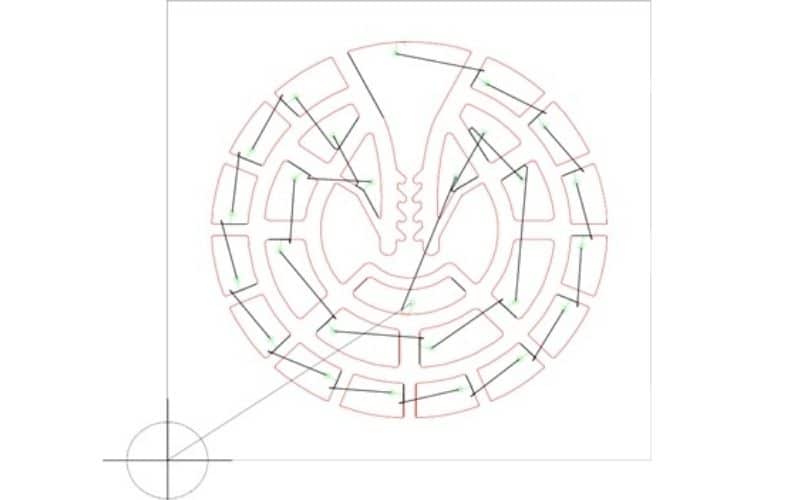

CASE: FAST CUTTING WITH PRECISION

CASE Fast cutting with the best precision in the world The micro abrasive waterjet produces…

CASE: Stent in Nitinol

CASE Information about the product Stents are used as support structures for surgery. These are…

CASE: SURGICAL CLIP IN NITINOL

CASE Surgical clip in Nitinol The Surgical clips are used in Laparoscopy. Examples of applications…

CASE: PRECISION CUTTING OF ZIRCONIA

CASE Precision cutting of Zirconia Micro abrasive water jet enables precision cutting of virtually all…

CASE: CUTTING NYLON, 17 MM

CASE Cutting 17 mm thick Nylon Finepart was challenged to produce a component in 17…