CASE

Comparison of W-EDM & Finecut FAW300

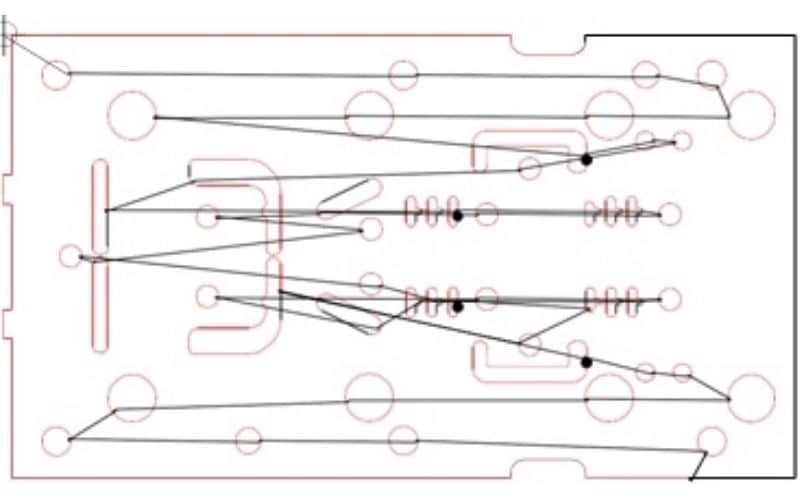

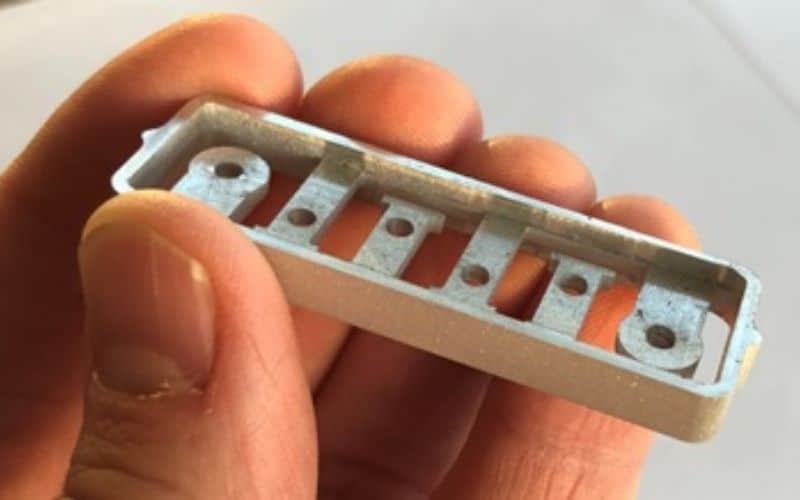

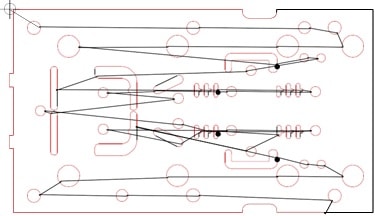

In this case we have compared the Finecut system with W-EDM for 1 millimeter shims.

Data for comparison

Material

Thickness

Dimensions

Detail cutting distance

Tolerance requirements

Stainless steel

1 mm

301 mm x 169 mm

3.351 mm

±0.02 mm

Wire-EDM Cutting

Cutting 10 sheets at the same time takes 1 hour 53 min for piercing and contour cutting with wire-EDM cutting. Hole making in separate machine, i.e. two set-ups.

Finecut FAW300

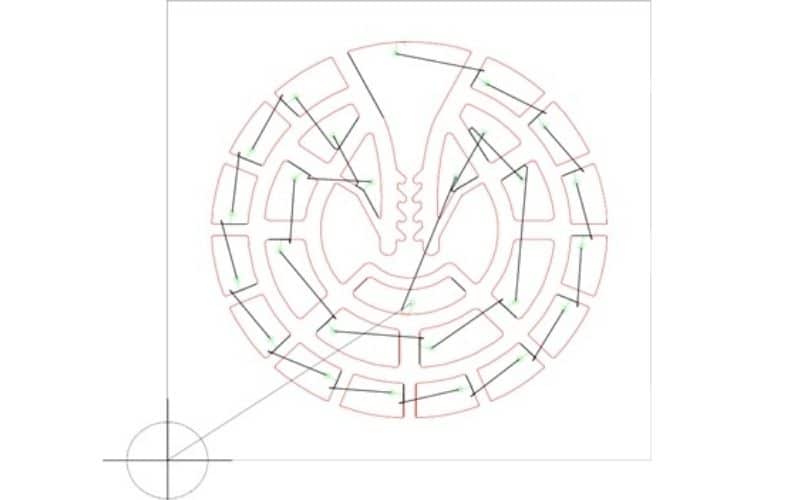

Erosion based cutting with a cut width of 0.3 mm. No heat impact. Hole piercing is done automatically.

Feed rate of maximum of 469 mm/min and minimum 182 mm/min in the corners gives a total cutting time, including piercing time, of 9 minutes and 52 seconds. With the Finecut system the surfaces does not require any after treatment.

The price for individual details with an operating cost of 15 Eur/h is 2.47 EUR/component.

CONCLUSIONS

Already without considering the pre-piercing required for the W-EDM the operational time reduction is 87% based on using the Finecut system.

Finecut Advantages

- Quick CAD/CAM preparation

- Simple fixturing

- Piercing and cutting in one set up

- Good surface – no finishing operation required