CASE

W-EDM vs. Finecut FAW300

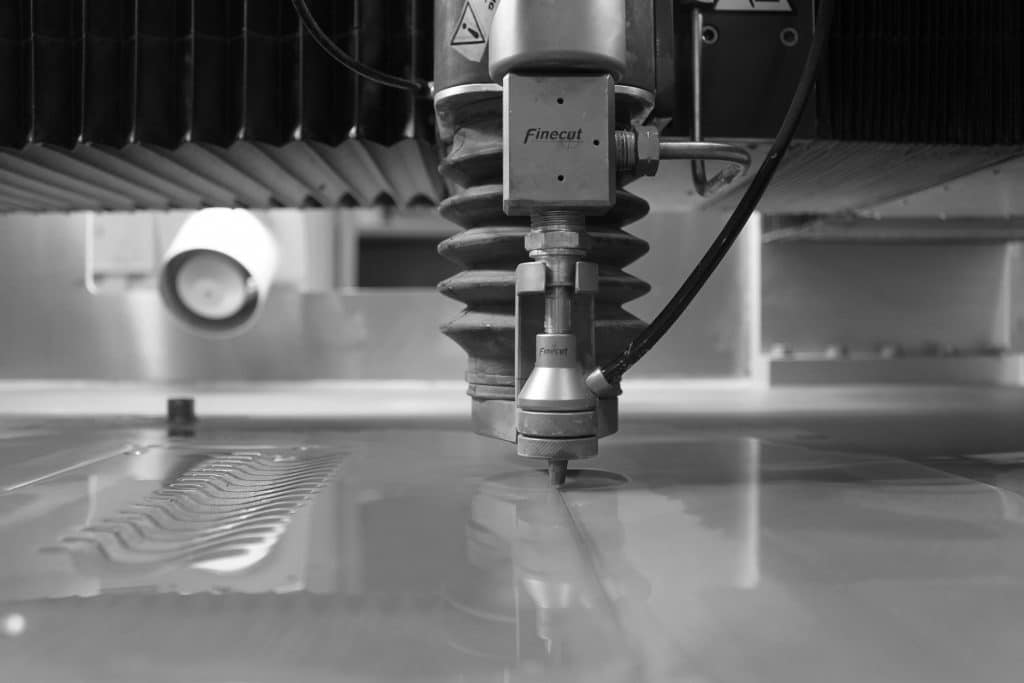

The Finecut process is a suitable complement to Wire EDM. The Finecut can provide tolerances down to ±10 microns depending on the part geometry and material. It is versatile and easy to setup. It pierces starting holes and cuts contours in the same setup. Cutting speeds may be up to 5 or 10 times faster, decreasing with material thickness.

Its ability to machine virtually all materials makes it the perfect complement to the W-EDM shop.

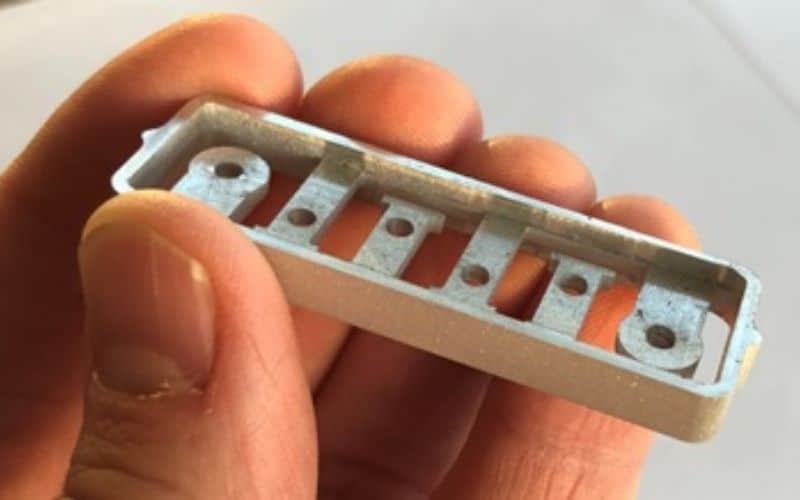

Aluminum part for microwave application

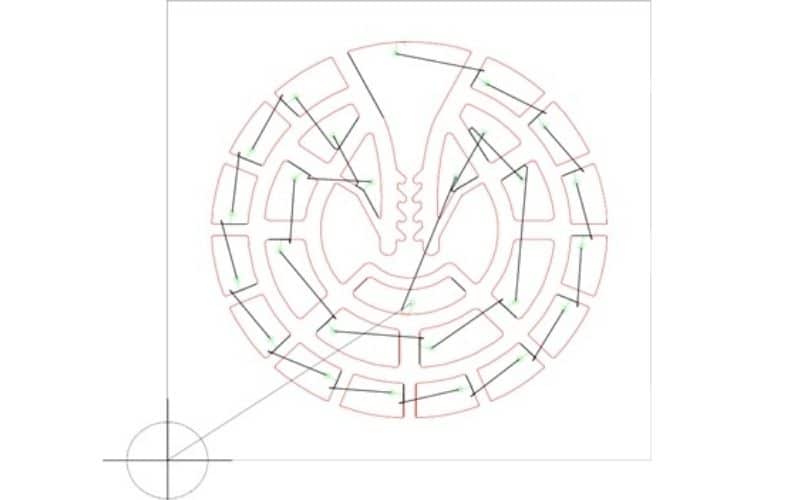

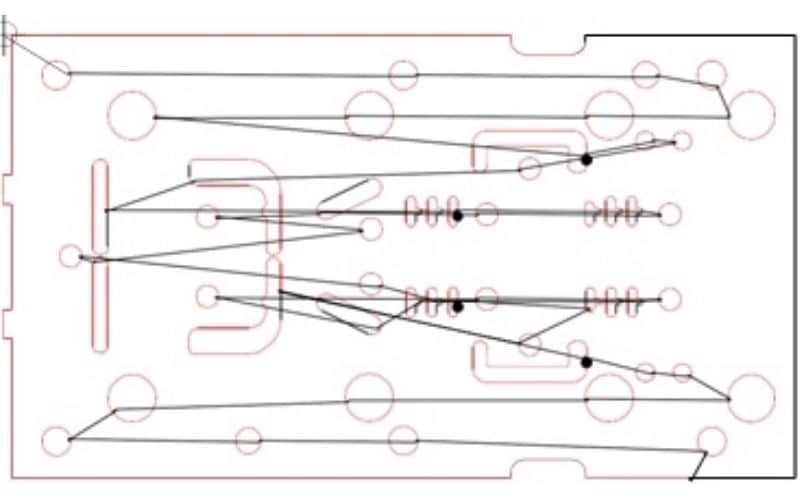

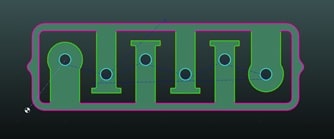

Toolpath

The image shows the tool path created from our CAD cam software (IGEMS).

• Pink = Slow cutting speed

• Green = Fast cutting speed

• Blue = Medium cutting speed

• Dotted Lines = Rapid positions

Wire EDM

Feed Rate

Approximate run time per part

Approx. setup time per plate

Component measured to within

Material thickness

Surface Finish

4mm/min

128 min

Unknown

±0.030mm

6 mm

Ra 3.5μm average

Finecut Micro Abrasive Waterjet Cutting

Feed Rate

Approximate run time per part

Approx. setup time per plate

Component measured to within

Material thickness

Surface Finish

Nozzle Diameter

35mm to 138mm/min depending where cutting.

9 min 33 sec

15-20 mins (Includes fixturing, guide pin holes & clamping arrangement)

±0.030mm

6 mm

Ra 2.3μm average

Ø 0.3mm with Ø 0.12mm Orifice, #230 Mesh Garnet Abrasive

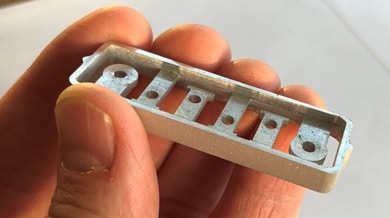

Finished Component

The image shows the finished component cut by micro abrasive water jet cutting. The plate had pockets milled by conventional milling and contours were then cut with micro abrasive waterjet.

Conclusions

Better surface finish

Quicker and much better surface finish compare to the Wire EDM, with no thermal wear or distortion.

No additional operations

No pre-operations – the waterjet can pierce straight through

Higher output

Higher cutting speed that gives higher throughput and consequently lower cost per part

A versatile machine tool to complement the W-EDM machine shop

The ability to cut non-conductive parts makes the Finecut machine a perfect complement to consider for any Wire-EDM shop to expand its machine tool inventory. Besides widening the scope of business opportunities, the moderate running costs and the ability to pierce and cut precise parts in the same setup with higher cutting speeds can offer economic benefits over the W-EDM, especially for thin parts. Aluminum and precious metals are easily cut, and so are also advanced engineered metals like Nitinol, alloys from magnesium or titanium without the hassle of recast layers or heat affected zones.

Must read: Micro Waterjet vs EDM Cutting

Benefits include

• Much quicker than W-EDM at virtually the same hourly cost

• Less handling with piercing and cutting in one set-up

• No wire breakage

• No heat generated during the process – no recast layers

• Cutting of thin segments with retained material properties

• Ability to cut non-conductive materials

• Combined materials / composite material can be cut

• Fine surface finish

• Recycling of precious metal possible