CASE

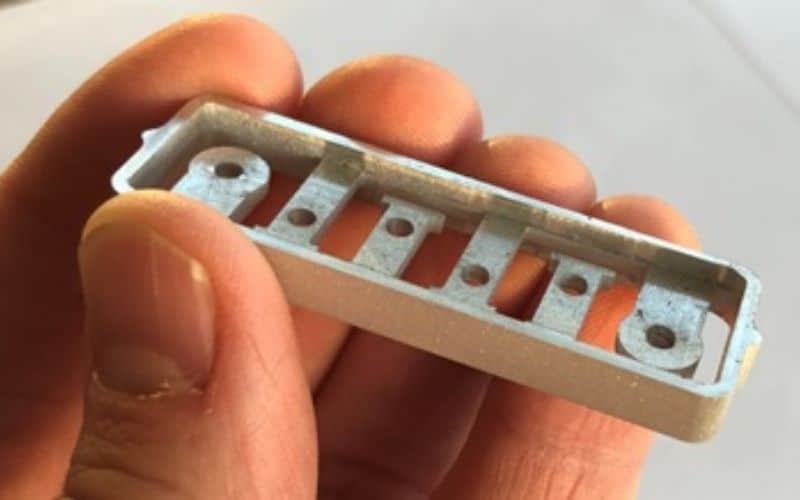

Cutting 17 mm thick Nylon

Finepart was challenged to produce a component in 17 mm Nylon. Due to the application and design, no taper was allowed on the finished part as the structure limits the possibilities of improving the surfaces in a post-process.

Part data

Material

Thickness

Dimensions

Cutting length

Requirements

Nylon

17 mm

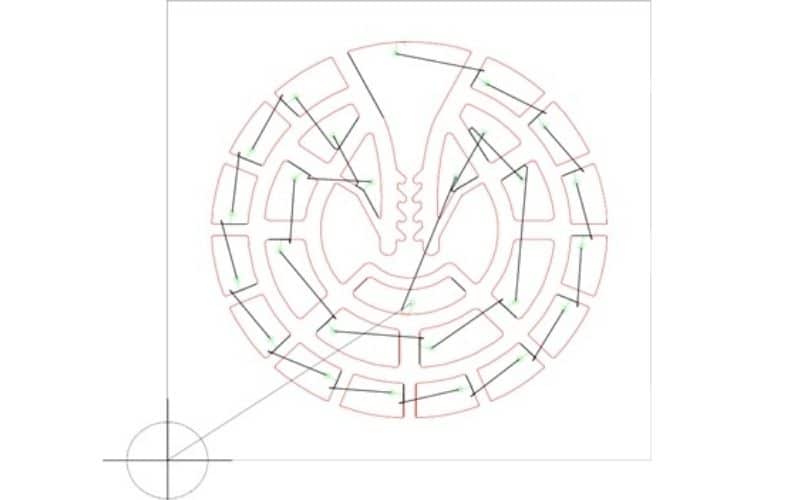

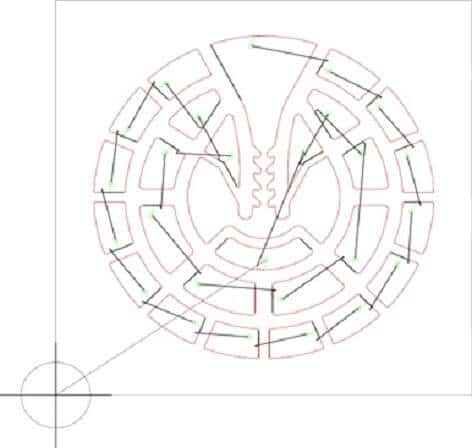

60 mm x 60 mm

849 mm

Straight cutting edges

Finecut FAW300

Erosion based cutting with 0.3 mm cutting width. No heat impact. Not limited to cutting only electrically conductive materials.

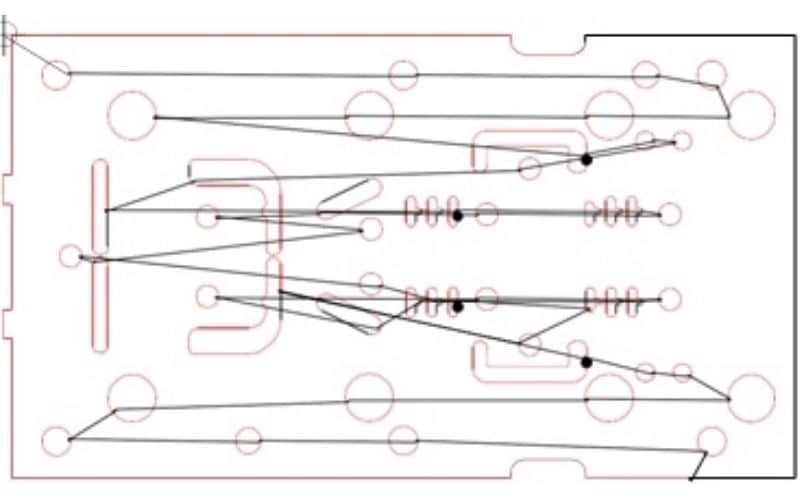

Cutting of material attached to the worktable. Piercing of holes is done automatically during start for each contour. Cutting speed adjusted to eliminate cut taper at edges.

| Preparation time | 15 minutes |

| Cutting time per component | 14.5 minutes |

| Cost for individual component | 3.63 EUR |

Cutting speed

| Max | 175 mm/min |

| Min | 60 mm/min (the latter is for corners and small radius) |

| Cutting time (per piece) | 11 min 30 sec, piercing: 2 min 10 sec |

Surface quality requires no further finishing.

The Finecut advantages

Great surface finish

No post-processing required

Piercing of start holes

No pre-process

Non-conductive

Cuts virtually all materials