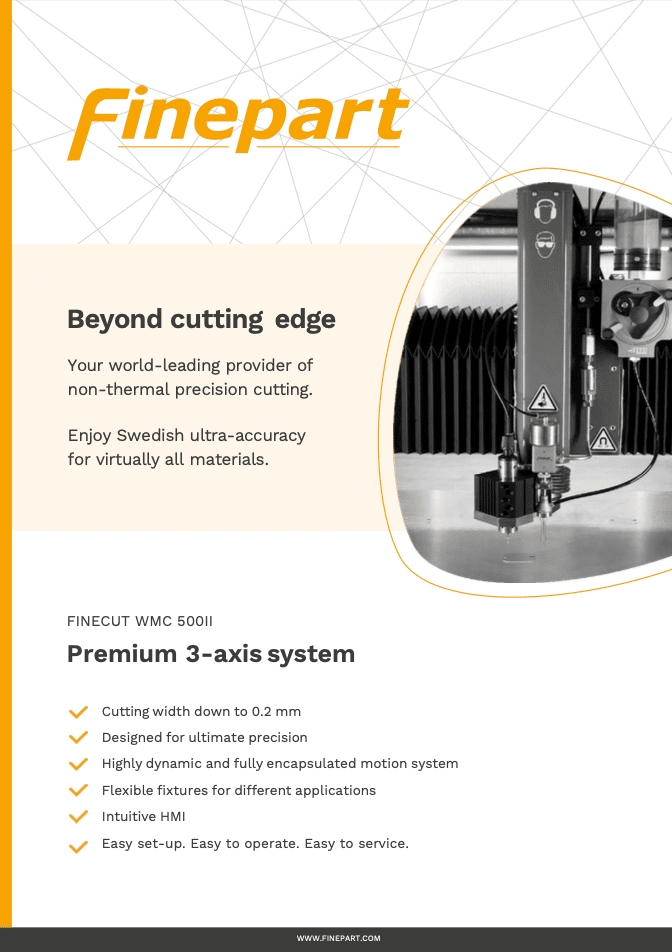

FINECUT WMC 500II 3X MICRO ABRASIVE WATERJET

Finecut 3-Axis Micro Waterjet Machine For Ultimate Precision

Finecut 3-Axis Waterjet Machine, a Premium Micro Abrasive Waterjet, Beyond Cutting Edge.

Cutting width down to 0.2 mm

Designed for ultimate precision cutting

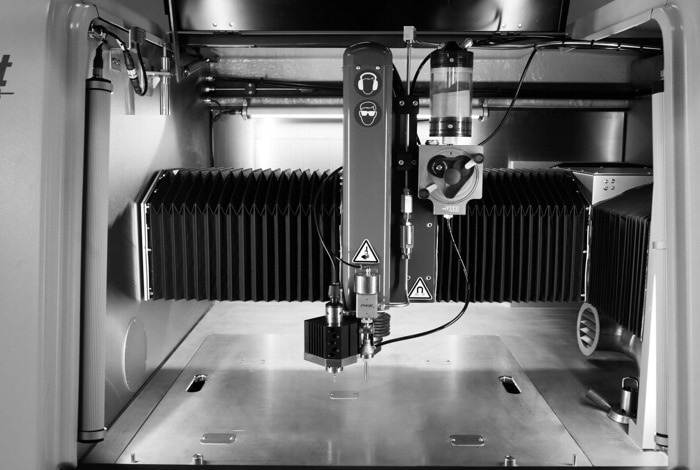

Highly dynamic and fully encapsulated motion system

Flexible fixtures for different applications

Intuitive HMI

Easy set-up. Easy to operate. Easy to service.

Get A Quote

Please provide your contact details and we will contact you shortly.

Finecut WMC500II 3X

Beyond Cutting Edge

Please add your contact details

We will email you the datasheet shortly

Ultra-High Precision Water Jet Cutting Machine

– with Finecut™ WMC 500 II Waterjet Machining Center

… Beyond Cutting Edge

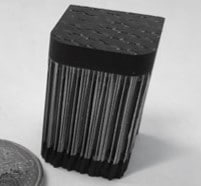

Micro Abrasive Waterjet technology is the proprietary cutting system of Finepart. It was developed to accompany the Finecut Waterjet Machining Center and together they bring the waterjet technology to a whole new level of precision cutting.

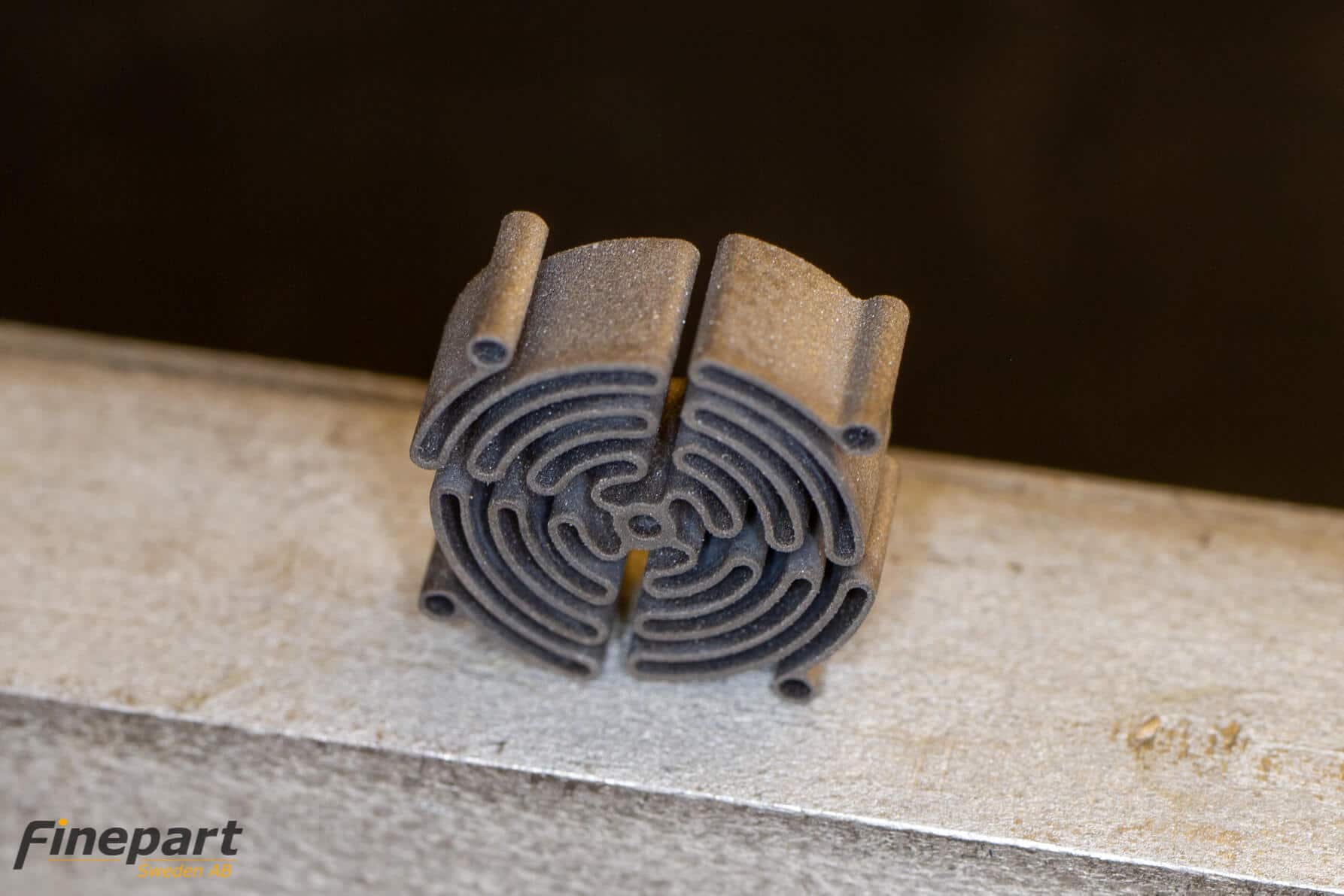

The micro abrasive waterjet process is a particle erosion based, non-thermal cutting process. This process can cut virtually all materials and produce a superior edge quality that does not change the material properties.

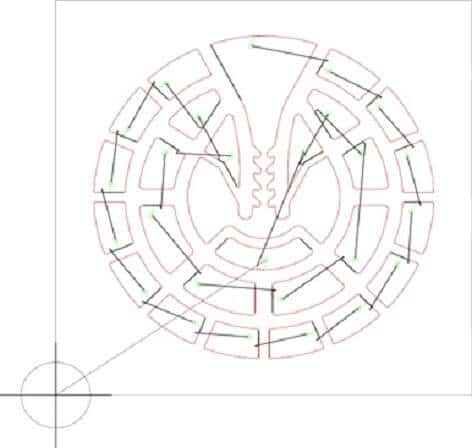

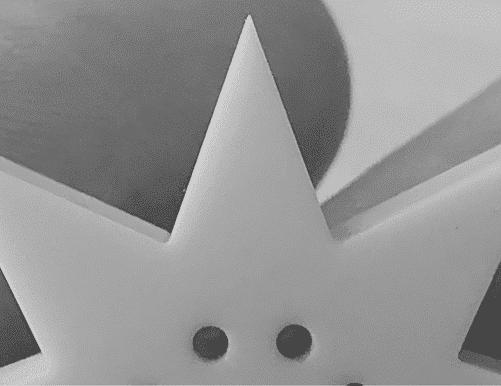

Moreover, the waterjet cutting process can pierce starting holes in the part and cut complex contours with minute features having radii down 0.1 mm.

Finecut 3-Axis Waterjet In Action

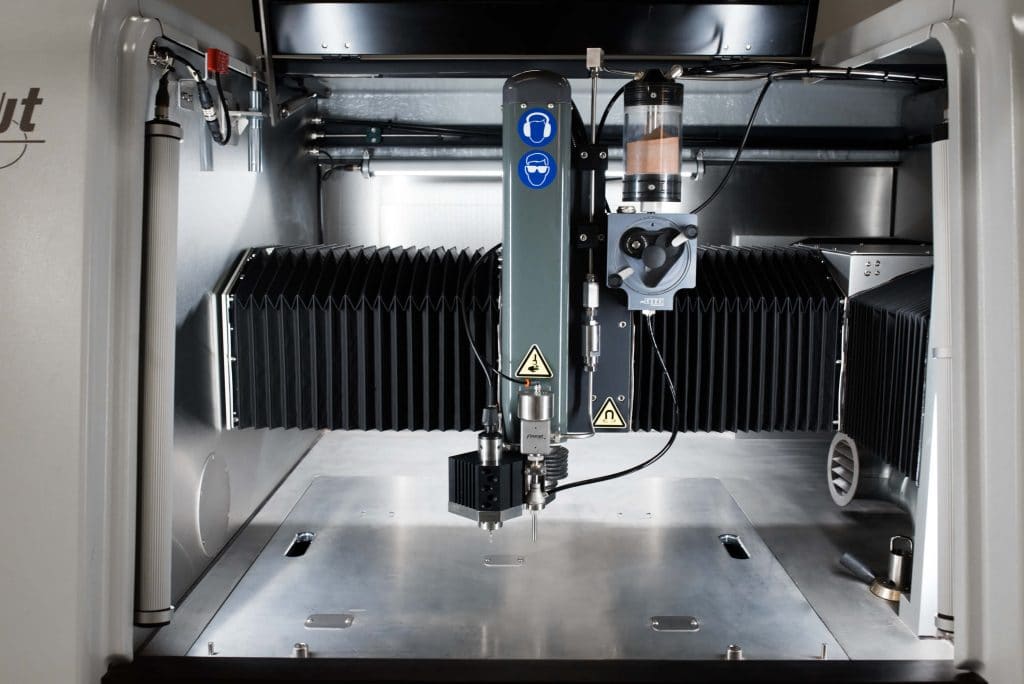

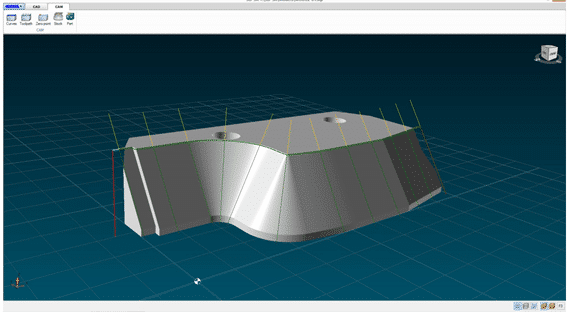

The Finecut™ WMC 500 II 3-axis waterjet is a new generation of precision machine tool using waterjet technology. The machine has a conceptual design that differs from traditional waterjet cutting tables in order to optimize accuracy.

With flexible fixtures for different applications, and a very intuitive HMI, the Finecut WMC 500II is very easy to set-up, operate, and service.

Finecut 3-Axis Waterjet Machining Center 500II type 3X

To produce narrow tolerance parts, the micro abrasive waterjet cutting system must also be accompanied by a very precise motion capability that accurately reproduces the programmed geometry. The Finecut™ waterjet cutting machines have been designed to optimise the part precision to a new level.

- Dynamic, high precision motion system featuring linear motors and ultra-high resolution thermally stable positional feedback.

- Cutting table mechanically attached to the motion equipment for ultimate precision.

- Rigidly built machine tool frame.

- Easy set-up of machine fixtures for a wide variety of different applications with optional solutions including live fixturing with synchronous motion.

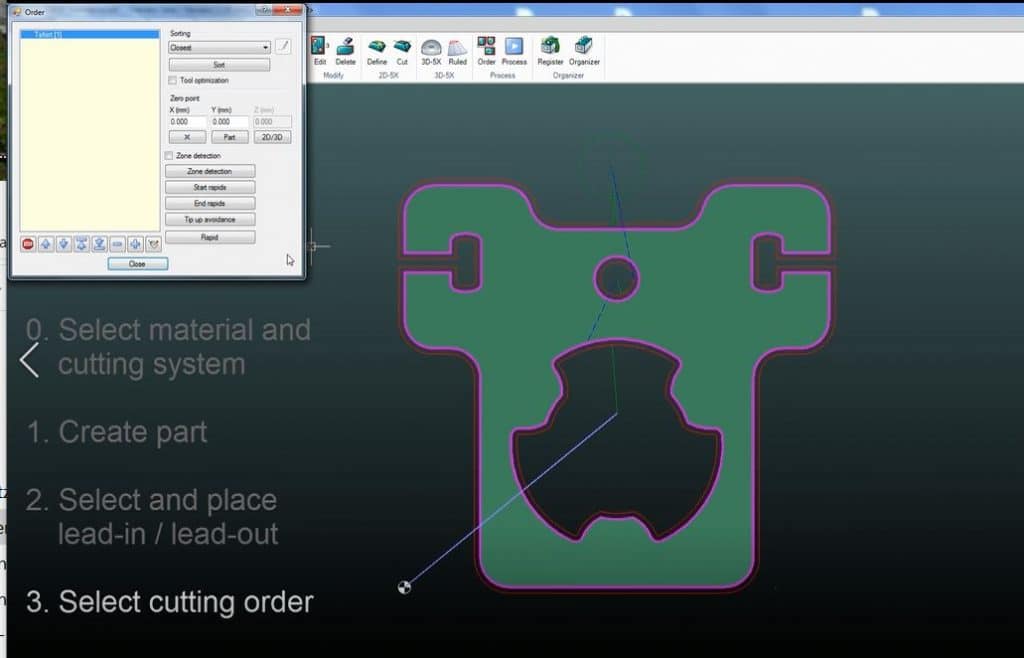

- Software and operators panel developed especially for abrasive waterjet cutting.

Technical Information

Finecut 500II type 3X

3-Axis Waterjet Machining Center

CNC Control:

Fanuc 31i-B5 and ALPHA Servo Drive with Nano Control

Motion system:

Linear motors and zero backlash reduction gears for precise motion

Absolute encoders:

Thermically stable Invar® linear encoders, 50 nm resolution

Motion Axis

- Linear servo motor drive on X-Y axes motion

- Precision ball screw servo drive on Z

- Positioning accuracy*: ± 2,5 µm

- Repeatability*: ± 2 µm

- Typical cutting tolerance ± 10 µm

- According to ISO 230-2

Cutting Speed

- Max cutting speed: 20 m/min

- Max traverse speed: 40 m/min

- Acceleration: 0.5g (X, Y axes)

Cutting System Option

- Fine Abrasive Waterjet: 0.2 mm, 0.3 mm.

- Abrasive Waterjet: 0.4 mm, 0.5 mm

Work Area & Cutting Table

- Cutting envelope (X, Y, Z): 500 mm x 500 mm x 80 mm

- Fixturing area: 700 mm x 700 mm (max depth 700 mm)

- Machine table size: 900 mm x 900 mm (W x D)

- Back door allows for inserting work pieces

Features For 3X Cutting Head

- Fitted with 5-axis controller – prepared for upgrade to 4X, ABX or B4X

Speak With A Waterjet Specialist

Cutting Head

Our fine abrasive waterjet cutting head is a Finepart proprietary design that is optimized for precision. A number of waterjet nozzle combinations are available for different applications.

Three Types of Cutting Systems

Depending on material, part complexity and level of miniaturization, our precision cutting can be made with any of our waterjet cutting systems that are available in 3 different categories:

- Fine / micro abrasive waterjet

- Conventional abrasive waterjet

- Pure waterjet

A range of sizes from 0.2 mm to 0.76 mm is available, whereas the larger jet facilitates a greater cutting power.

Cutting Table & Work Area

In the Finecut™ waterjet cutting machine the material is clamped to the machine work table and mechanically coupled to the motion system.

The catcher tank that dissipates the jet energy after cutting is separated from the work table structure in rubber suspension in order to minimize the influence of vibration.

Flexible Fixturing

3D part geometry can be cut with assisting additional servo axes that manipulates the part synchronously to the cutting motion in order to provide access for the cutting jet.

A variety of innovative fixturing’s solutions can be adopted depending on the part requirements. It is also easy to make your own fixtures, using the machine’s palletized fixturing solutions. For repeat orders, this solution enables you to quickly set up and produce.

HMI and CNC Control System

The Finecut™ waterjet cutting machines feature our own Finesoft HMI user interface and high-end control & servo system granting simplicity in operation without compromising ultimate precision, reliability and versatility.

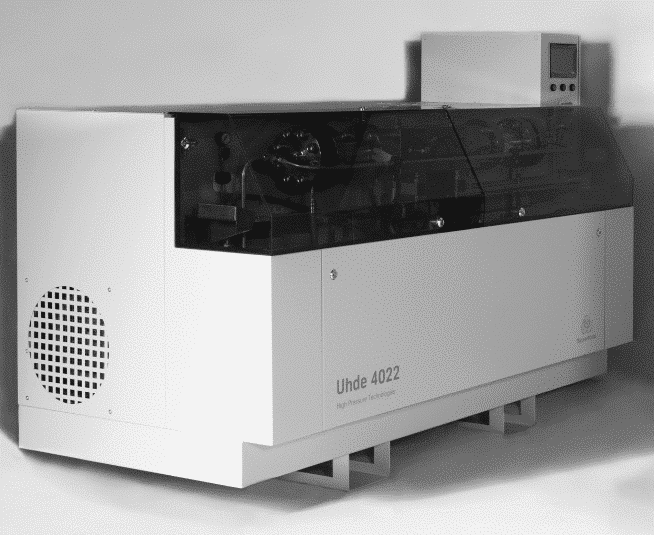

High Pressure Intensifier Pump

The Finecut™ 3 axis waterjet FINECUT WMC 500II is supported by a 4.000 bar high pressure intensifier from Uhde High Pressure Technologies. This pump provides a smooth pressure profile with a minimum of pressure fluctuation.

Advanced Option Portfolio

The 3 axis waterjet Finecut FINECUT WMC 500II can be equipped with several options like measuring probe, 5-axis cutting head, turning axis, drilling unit, vision system, and more.

We also develop new options that serve the customer’s needs for efficient production. All options are retrofittable to existing machines.

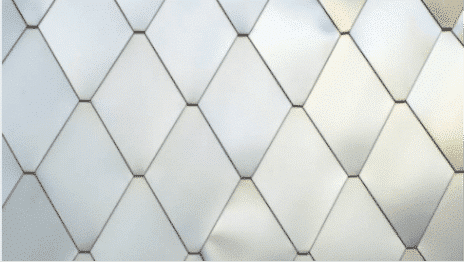

Materials That Can Be Cut With Finecut 3-Axis System

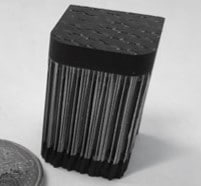

The Finecut™ WMC 500II 3-Axis waterjet machine is a highly dynamic and fully encapsulated motion system 3 axis cnc waterjet cutting machine that can cut virtually any material with a width down to 0.2 mm.

Metal Alloys

Titanium, aluminium, brass, copper, stainless steel, magnesium alloys, shape memory alloys e.g. Nitinol, tool steel

Brittle Materials

Glass, mother of pearl, silicon

Composites

Carbon fiber reinforced polymer (CFRP), glass fibers, FR4

Soft Materials

Rubber, Wood

Engineering Ceramics

Zirconia, alumina, crystal sapphire, silicon carbide

Sandwich Materials

Honeycomb structures

Get a Test Cut & Discover our great precision

Always with Finecut

Flexible fixturing for any application

several solutions for different applications and requirements

State Of The Art Machine components

latest technology for high dynamic capacity and accuracy

Additional functions offer practical solutions

great assisting tech for improved automation, setup and handling

High-end support systems from reliable partners

high pressure technologies for enhanced precision and control

User-friendly panel with Finesoft ™ software

easy to use interface for software & operators panel

Retrofittable developments

always gain from the latest technology and innovations