CASE

Information about the product

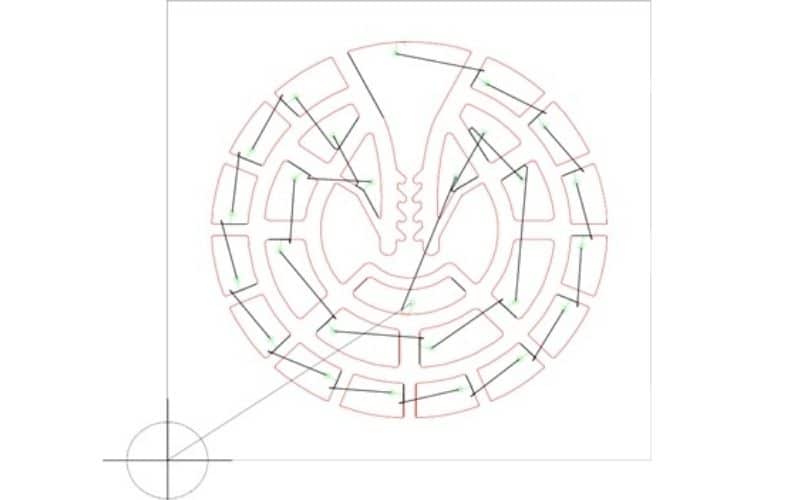

Stents are used as support structures for surgery. These are often manufactured as tubes or in flat form which is then rolled into a tube. Examples of applications are blood vessels, intestines, throat, etc. These can be manufactured in different materials. In the present case, Nitinol (shape-memory alloy) is used, which has the property that it can be “programmed” to regain a desired shape at a certain temperature, for example 37 degrees centigrade.

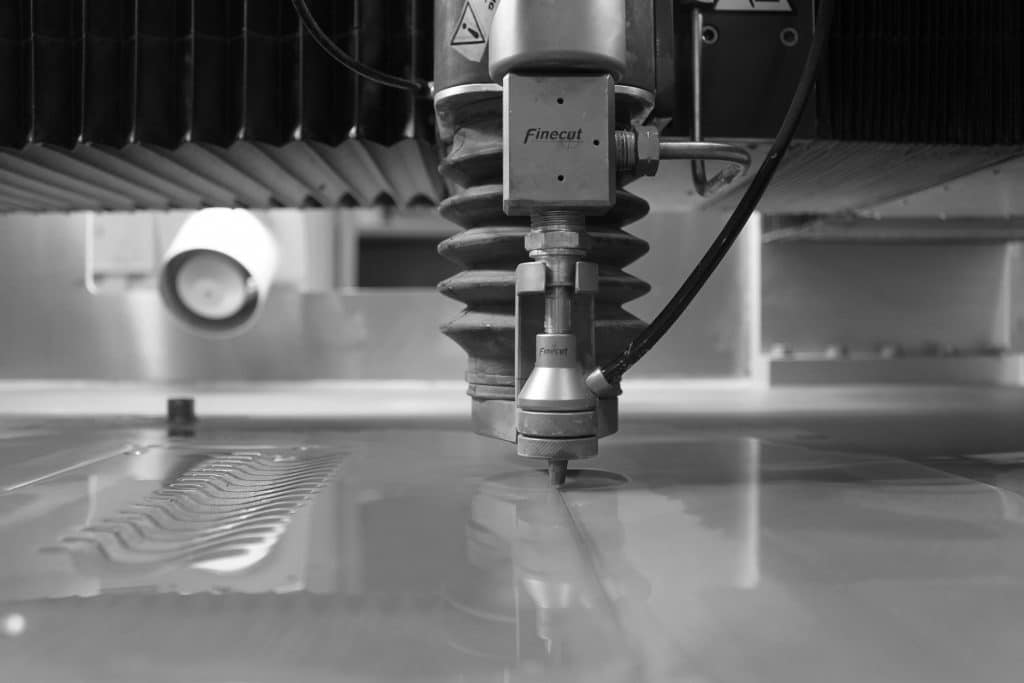

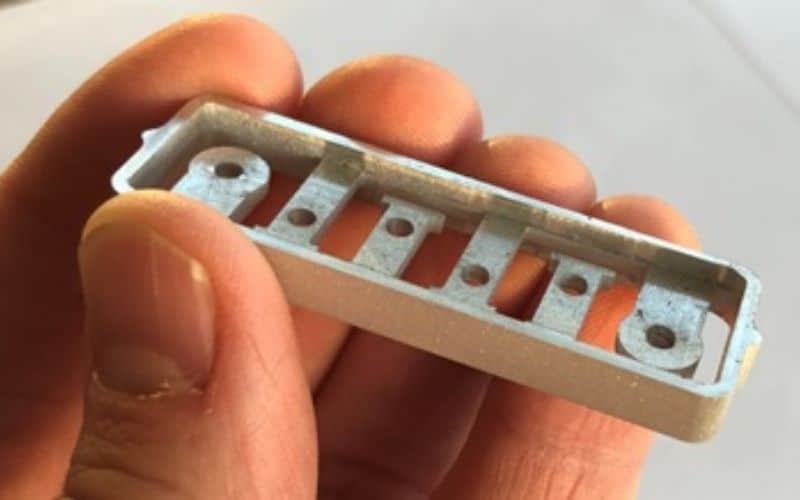

At that point, the material then becomes very strong and can withstand pressure from nearby tumors, etc. There are high demands on surface integrity. The product must be free of sharp burrs and oxides. Previously, the customer has processed these products with a waterjet-guided Laser. This has limitations with a machining speed of about 30 mm/min and heavy slag formation. Alternative machining methods was performed with Finecut™ machine from Finepart Sweden AB with great results that can be seen in the conclusions.

Data

| Material: | Nitinol |

| Material thickness: | 0.40 mm |

| Length of cut: | 2 522 mm |

| Annual volume: | 5 000 pcs |

Wire-EDM Cutting

Cutting 10 sheets at the same time takes 1 hour 53 min for piercing and contour cutting with wire-EDM cutting. Hole making in separate machine, i.e. two set-ups.

Learn more: Micro Waterjet vs EDM Cutting – A Detailed Comparison

Finecut FAW300

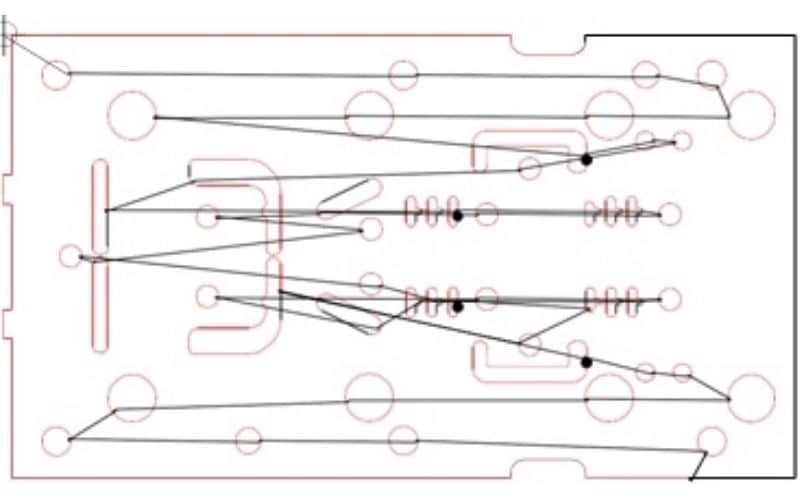

Erosion based cutting with a cut width of 0.3 mm. No heat impact. Hole piercing is done automatically.

Feed rate of maximum of 469 mm/min and minimum 182 mm/min in the corners gives a total cutting time, including piercing time, of 9 minutes and 52 seconds. With the Finecut system the surfaces does not require any after treatment.

The price for individual details with an operating cost of 15 Eur/h is 2.47 EUR/component.

Conclusion

- 4-times higher speed than the waterjet-guided laser, i.e. lower total cost

- No generated burrs, oxides or heavy slag formation after cutting

- The typical tolerances of component are within ±10 µm

- No changes in the material structure after cutting

- 50% lower investment cost with the Finecut

Cutting with the Finecut

| Cutting system: | FAW300 |

| Number of set-ups: | 1 |

| Average cutting speed: | 126 mm / min |

| Operational cutting time: | 21.2 min |

| Finecut operational cost: | 5.16 EUR/pc |