What is Micro Abrasive Waterjet?

The micro abrasive waterjet is the ideal tool for ultimate flexibility in fine mechanics production with capability to cut, drill and also remove material three-dimensionally (turning and milling). It can be used in virtually all materials. It is a non-thermal process that does not change material properties. The fact that it is effective also in combined materials is an important advantage in cases of materials having disparate material properties such as for example carbon fibre reinforced epoxy with mold-in titanium parts.

Small jet size

Micro abrasive waterjets operate like traditional abrasive waterjets and share the general benefits of the process such as non-thermal cutting of virtually any material. However, this new technology takes the results to a higher level of accuracy. Whereas traditional abrasive waterjets have diameters down to 0.4 mm (0.38 mm), micro abrasive waterjets are even finer. Typical micro abrasive waterjet sizes are 0.3 mm and 0.2 mm and ongoing development will soon result in even smaller sizes.

High precision, nice surface!

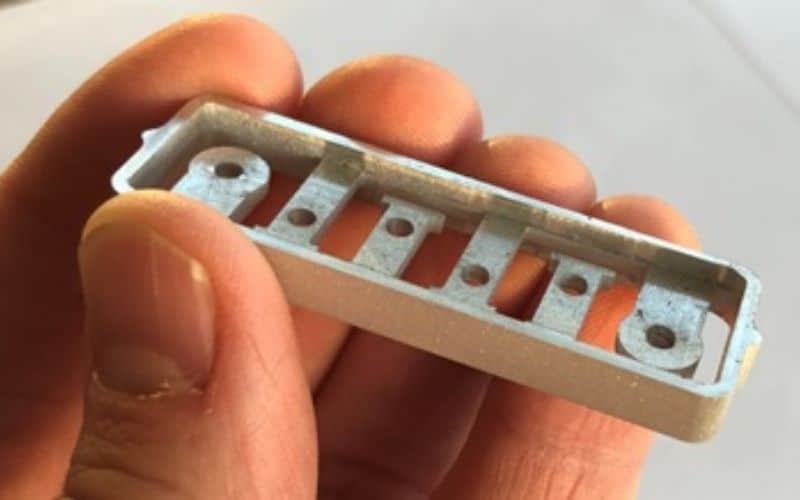

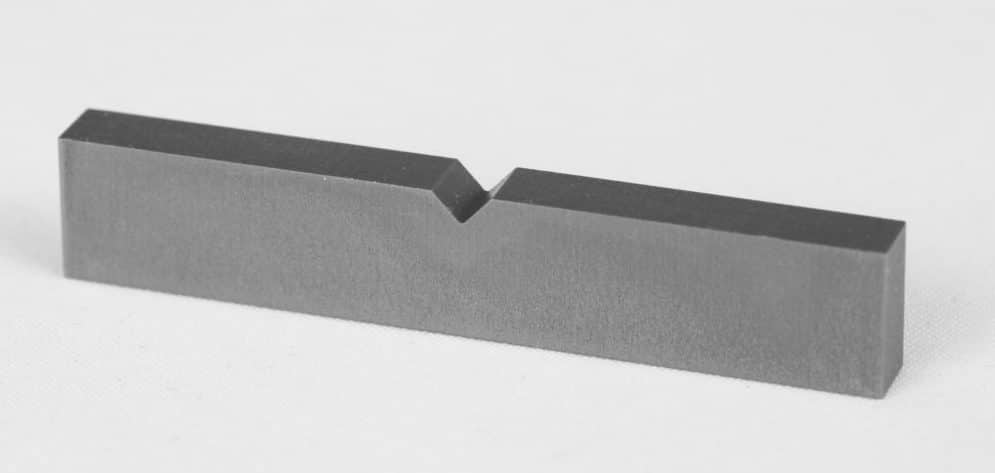

A micro abrasive waterjet can cut minute parts with high precision and excellent surface finish. Moreover, it can in fact also be used to cut precision features in larger parts. Depending on the part material and size, tolerances can come down to ±0.01 mm. Normally, surface roughness values below 1.6 µm (Ra) can be accomplished, and for hard material roughness values below 0.8 µm (Ra) are often obtainable.

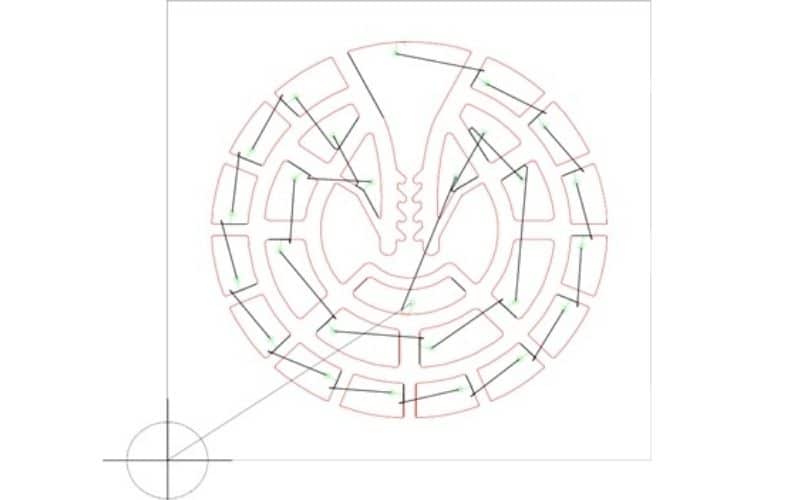

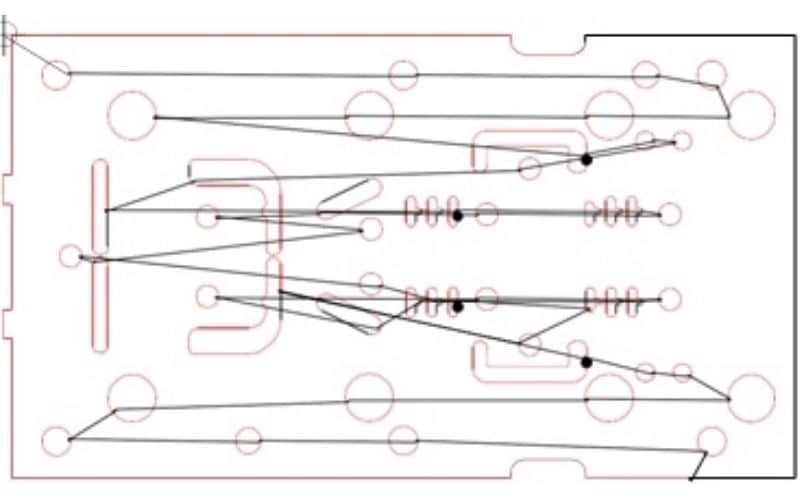

Ideal for fine features

The small jet diameters has the ability to work omnidirectionally and allows for fine features to be cut in intricate patterns with minimum radii down to ca 0.1 mm. Part sizes we cut vary greatly from sub-millimeter size to large 50 kg parts. The part complexity handled can include both complex geometries having down to 0.1 mm wide sections in flat stock, and complex shell structures that require live fixtures that can re-orient the workpiece for accessibility and even move it synchronized to the jet motion. For this type of machines, work fixturing solutions are an important part of a successful application.

Machine design for precision

Nevertheless, for the micro abrasive waterjet to obtain this level of precision it must be handled by a specially designed machine system that is a capable precision machine tool. A machine designed and built for stable handling of the jet and workpiece with very high accuracy is required.

Finecut WMC500II

The Finecut WMC500 II uses state-of-the-art technology and innovative solutions to optimize performance. It has a controller that uses nanometer interpolation to ensure smooth motion. The machine design utilizes a direct drive motion system that operates at micrometer precision, built so that the tool motion is mechanically linked to the part being machined. High resolution absolute resolvers and a design for thermo-mechanical robustness promote high precision. The machine is available in 3-, 4-, and 5-axis configurations.