Precision ceramic machining – In this article we provide the context for cutting and precision machining engineering ceramics, why it is hard to cut, and how the Finepart 5-axis micro abrasive waterjet machine can help you meet tight tolerances and reduce processing times.

The challenge of precision cutting ceramics

Ceramics are hard, brittle materials that can handle high compressive stresses but they also fracture more easily under shear or tensile loads. This unique combination of properties is also what makes ceramics so challenging to cut or machine with traditional machining methods. They significantly increase tool wear rates and experience a greater risk of irreparable damage from cracking.

By avoiding direct contact between the cutting tool and the hard ceramic part, waterjet cutting machines can dramatically reduce costs associated with tool wear and can lower the stress applied to ceramic parts. Additionally, modern micro abrasive waterjets can use 5-axis CNC movement to remove taper, create advanced shapes and perform machining operations.

Why are ceramics difficult to machine?

Ceramics can be very demanding to machine accurately, especially when compared to commonly machined metal and plastic alternatives. One of the biggest reasons for this is that, unlike other materials, ceramics experience almost no deformation before cracking.

You can see this for yourself by how easily a metal wire or paperclip can be bent back and forth repeatedly before breaking. A small glass tube or rod, however, would snap before it experienced any significant bending or deforming.

The brittleness and deformation properties of ceramics make them “chip” apart in less predictable ways. Cutting tools cause fragments of the ceramics to chip off, forming a rough surface texture. But if the stress from the cutting tool is too high, or the ceramic has internal weaknesses, a crack can propagate through the part, causing it to break. On top of this, a ceramic’s hardness makes cutting slow and wears out tools faster.

Challenges of waterjet cutting ceramics

One of the side effects of using an erosion-based machining method when cutting engineered ceramics, however, is the formation of kerf taper. The shape of the cut produced by a waterjet is influenced by a variety of factors, including things like:

- Workpiece material and hardness

- Workpiece thickness

- Abrasive quality

- Cutting speed

Without accurately adjusting for these factors, the material at the top of the cut could be removed at a different rate than the bottom of the cut, which results in a taper cut.

Benefits of Micro Abrasive Waterjet Machining of Ceramics

Up until recently, methods like milling and drilling were the only viable options for machining ceramics. However, the emergence of modern machining methods has introduced alternatives with new capabilities.

Older waterjets were only capable of cutting softer ceramic materials. They relied on 3-axis cutting operations and needed to make full-thickness cuts, making machining impossible.

However, modern micro abrasive waterjet technology can cut through most materials at an impressive rate. And the 5-axis waterjet can create more advanced shapes and work faster to boost productivity.

The Ceramic Machining Process Using a Finecut Micro Abrasive Waterjet

As a 100% cold-cutting process, micro abrasive waterjets use a powerful, highly focused jet of water to accelerate abrasive particles to high speeds. The water and abrasives cause micro-impacts on the surface of the ceramic workpiece, eroding away tiny fragments of the ceramic workpiece. The small but rapid collisions gradually wear away the ceramic material positioned under the waterjet’s nozzle, all without overstressing the part.

CASE

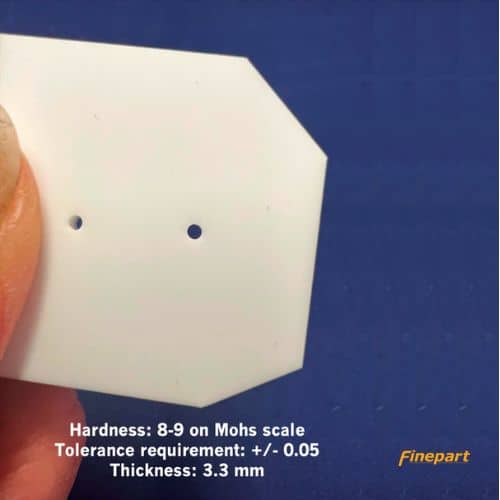

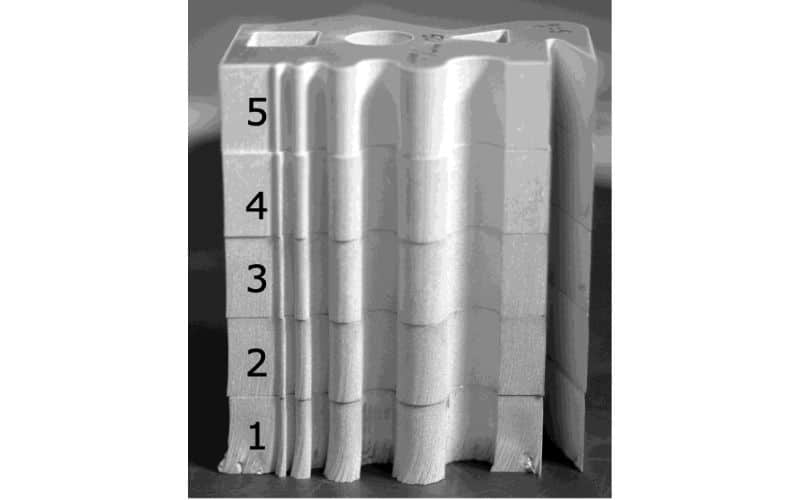

Cutting Al2O3 (Alumina) 97.5%, 3.3 mm thickness, using 5-axis cutting

In the engineered ceramics cutting example we showcase that with very hard material, like engineered ceramics, there is a point where cutting speed, type of abrasives material, and waterjet control software is not enough to remove taper entirely. At this point it requires a 5 axis micro waterjet that allow for adjusting the cutting angle and provide the precision cut and smooth surface that high quality ceramics parts require.

To demonstrate the changes in processing times between a Finepart 3-axis and a 5-axis micro waterjet, we are sharing the results of an in-house study performed using the alumina part shown below.

Alumina sample part information:

- Hardness: 8-9 on Mohs scale

- Tolerance requirement: +/-0.05 mm

- Thickness: 3.3 mm

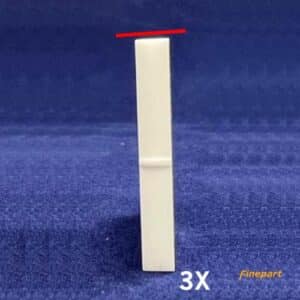

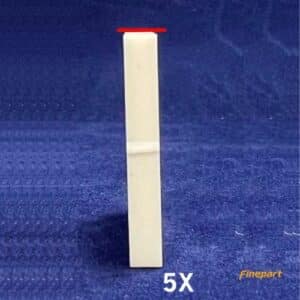

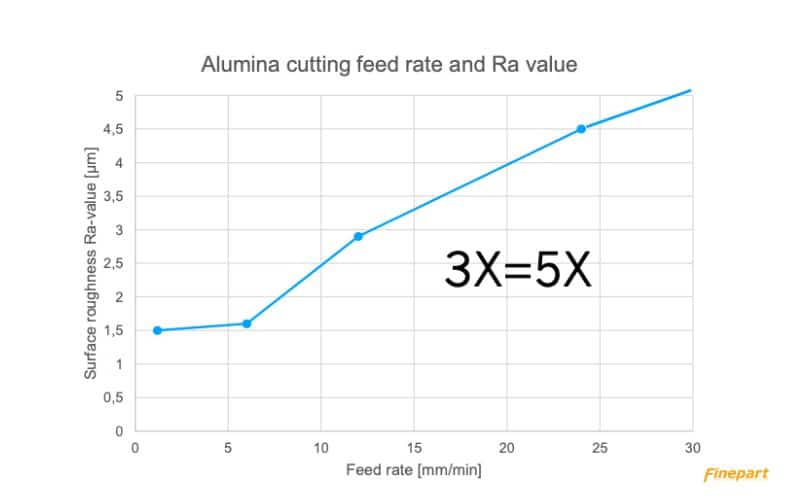

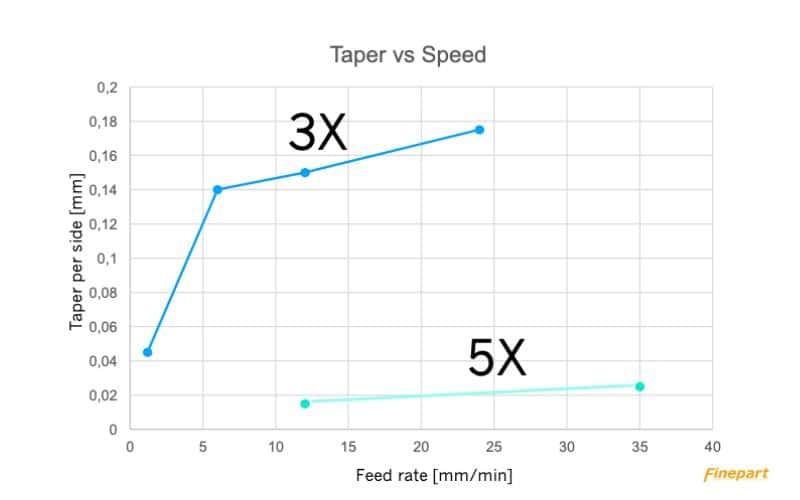

The alumina sample part was then cut using both a Finecut 500II 3-axis and Finecut 500II 5-axis waterjets over five different cutting speeds. The degree of taper and surface roughness values were measured and compared.

| Feed rate | Ra-value | Taper (Finecut 3 Axis) | Taper (Finecut 5 Axis) | |

|---|---|---|---|---|

| Part 1 | 1.2 mm/min | 1.5 | 0.045 | |

| Part 2 | 12 mm/min | 2.9 | 0.15 | 0.015 |

| Part 3 | 24 mm/min | 4.5 | 0.175 | |

| Part 4 | 35.1 mm/min | 5.0 | N/A | 0.025 |

| Feed rate | Ra-value | Taper (Finecut 3 Axis) | Taper (Finecut 5 Axis) | |

|---|---|---|---|---|

| Part 1 | 0.047 in/m | 1.5 | 0.045 | |

| Part 2 | 0.47 in/m | 2.9 | 0.15 | 0.015 |

| Part 3 | 0.94 in/m | 4.5 | 0.175 | |

| Part 4 | 1.38 in/m | 5.0 | N/A | 0.025 |

Cutting speed increased 29 times within tolerance!

The results show that the 5-axis micro abrasive waterjet created less taper than the 3-axis machine, even at the highest feed rate tested. This allowed the 5-axis waterjet to meet the ±0.05 mm (0.002″) tolerance requirement of the test even at a cutting feed rate 29 times higher than the 3-axis waterjet.

The maximum feed rate achievable for the 3-axis waterjet on this part was 1.2 mm/min (0.047 in/min) while the 5-axis waterjet was able to achieve a 35.1 mm/min (1.38 in/m) cutting speed.

The taper can be compensated with 5-axis cutting but Ra value will be affected

The biggest downside of this increased cutting speed was that the surface roughness increases at higher speeds. However, this still gives fabricators with a 5-axis micro abrasive waterjet the flexibility to adjust their parameters in order to meet quality requirements in the most efficient way possible.

Overall, the maximum speed of the 3-axis waterjet was highly dependent on BOTH taper tolerance and surface roughness requirements. Meanwhile, the 5-axis micro waterjet was not limited by taper requirements, so operators can increase feed rates until it reaches a limit established by surface roughness criteria.

Ra-value may be the limiting factor in speed selection

For 3-axis ceramics cutting, a significant speed reduction is required to reduce taper

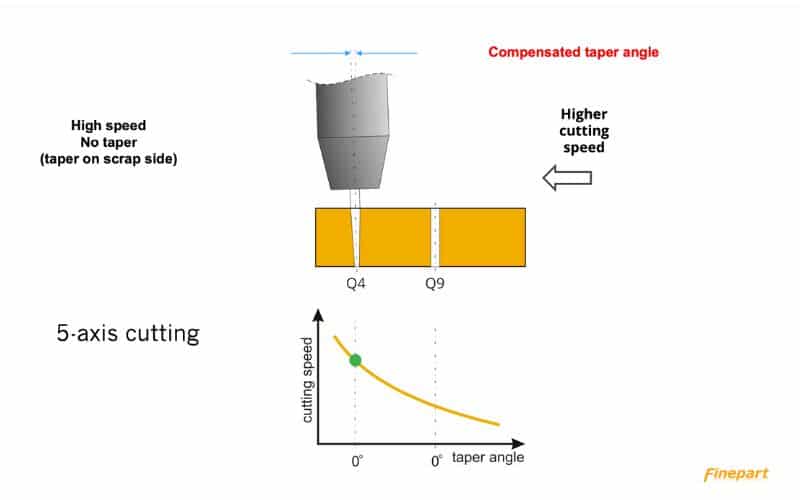

Compensation can significantly reduce the taper at a given cutting speed.

3 adjustments to improve finished part quality

While the most rapidly-cut segments of both these sample parts show poor quality cuts, it’s also clear that the quality can be substantially improved through simple changes:

- Reducing cutting speeds in challenging areas

- Optimizing the cutting speed for the material and thickness, and

- Adjusting the cut angle

Superior precision machining ceramics using a Finepart 5-axis micro waterjet

The results show that the Finepart 5-axis micro abrasive waterjet created less taper than the Finepart 3-axis machine, even at the highest feed rate tested. This allowed the 5-axis waterjet to meet the ±0.05 mm (0.002″) tolerance requirement of the test even at a cutting feed rate 29 times higher than the 3-axis waterjet.

So in conclusion:

- Finepart 5 axis micro waterjet will provide you with the desired surface finish and precision cutting because it has the flexible cutting angle adjustments needed to remove taper in a hard material like engineered ceramics.

- Plus it provides a cutting speed 5x higher which provides both the productivity and cost benefits for better profitability.

Economical benefit of 5 axis cutting ceramics

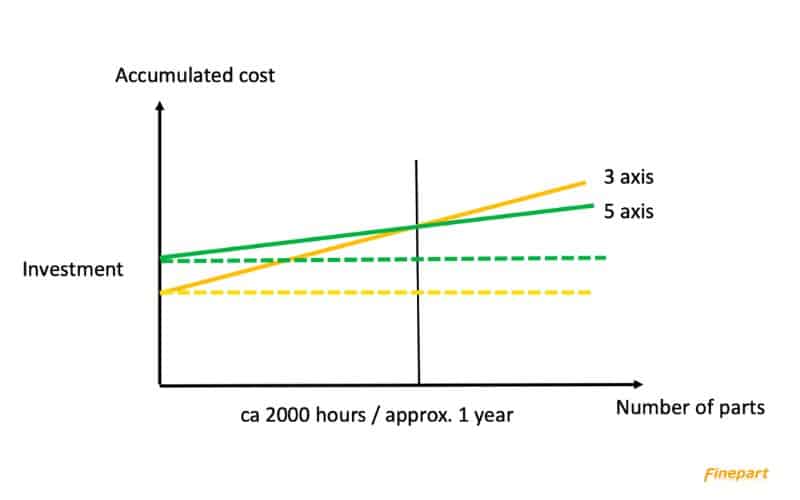

Does the shorter cutting time achieved by 5 axis cutting really justify the extra cost?

Return on investment

If you need the option to rapidly increase throughput or create more advanced ceramic part designs, you should also consider selecting a 5-axis micro abrasive waterjet machine.

A 5-axis waterjet machine can perform all the same operations as a 3-axis machine, but it can also cut at inclined angles to achieve more complex geometries. This improves the versatility offered by a 5-axis waterjet whenever advanced designs are being processed.

Achieving an accurate 90° cut edge

And in the case of waterjet cutting ceramics, it can be more difficult than with other materials to maintain an accurate 90° cut edge using standard 3-axis waterjet cutting equipment. A 5-axis waterjet can actually improve precision when cutting ceramics vertically, achieving a more consistent 90° edge.

One of the most unique advantages of a 5-axis micro waterjet, however, is the ability to increase cutting speeds by carefully adjusting the nozzle’s cutting angle.

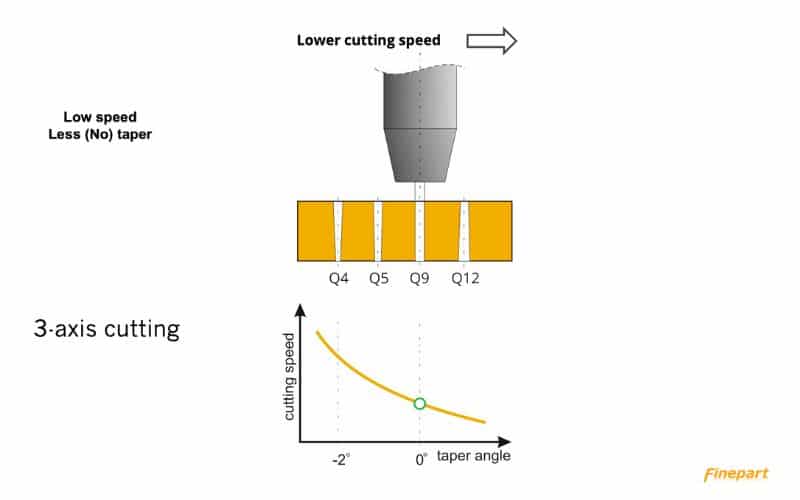

Reduce cutting speed to create a square 90° edge

If the cutting speed on a 3-axis waterjet is too high, it will form V-taper along the cut. This means the cutting speed of a 3-axis waterjet must be optimized for the part in order to create a square 90° edge. Too fast or too slow, and the edge geometry will be compromised.

But a Finepart 5-axis waterjet can get around this limitation by adjusting the nozzle orientation to account for the V-taper of the cut. The result is a much faster cutting speed while still maintaining a square 90° edge on the part’s side of the cut edge.

But do the shorter cutting times really justify the extra cost?

That depends on how the equipment will be used by each shop. But the added versatility and faster cutting speed potential of a 5-axis micro abrasive waterjet machine can quickly show a positive return on investment, often within a single year.

Read our full article on 5-axis vs 3-axis waterjet cutting for more information.

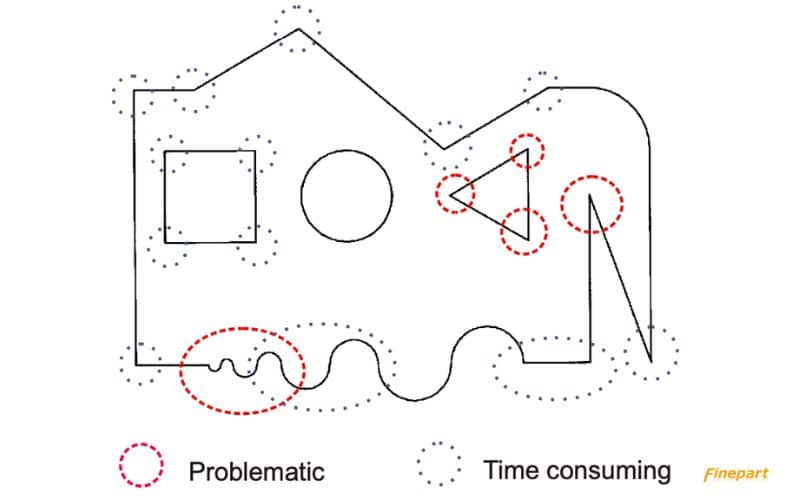

How the jet lag at different speeds affects the part precision

Another unique challenge that can face abrasive waterjets is the lag between the nozzle movements and the cut path. This effect is most pronounced at sharp corners and intricate details.

The impact of waterjet lag on precision cutting

The following sample component highlights the effects of waterjet lag on creating precision ceramic components which a Finepart micro waterjet can easily handle with the intelligent waterjet control system that automatically adjust the cutting speed where needed.

Waterjet cut path challenges

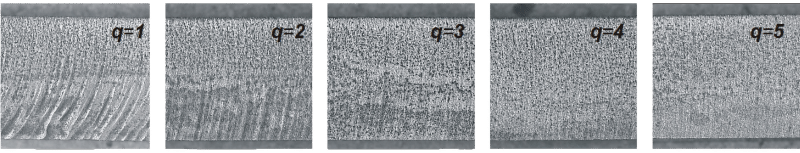

Cut quality classification

The cuts performed in both these examples have been assigned a cut quality class ratings between Q1 and Q5 based on the surface finish of the cut edge.

For an ideal waterjet cut edge, there should be no striations or taper, resulting in a quality class rating of Q9. This can be achieved by reducing cutting speeds in challenging areas, optimizing the cutting speed for the material and thickness, and adjusting the cut angle, like we did in the case above.

Abrasive waterjet has a cut quality classification ranging from cut quality classification Q1-Q9, where Q9 has no taper and no striations. Q1 is a separating cut with striations visible on the surface, similar to the abrasive waterjet cut quality classification.

The cut quality classes Q5-Q9 do not have much difference in surface roughness, it is more the conicity in the cut that differs between the different quality classes, where Q9 has totally parallel walls.

Premium Ceramic Machining with Finepart Micro Abrasive Waterjets

Finepart is the leading manufacturer of high-precision micro abrasive waterjets.

CNC machining ceramics has traditionally been limited to CNC milling and drills, but a new precision ceramic machining process has emerged for producers to choose from. For the highest part quality and the best value, you may want to consider the Finecut 5-axis micro waterjet.

With the ability to cut through almost any material, including many high-hardness materials and ceramics, micro waterjets make a great addition to your machine shop or production facility.

The added versatility offered by the Finecut 5-axis micro abrasive waterjet machine means you can increase production capacity while still meeting tight tolerance requirements.

BEYOND CUTTING EDGE

Finecut Micro Waterjet Series

Easy to operate 3, 4, and 5 axis micro waterjet machines for high precision cutting ceramics parts with ultimate edge and surface finish in one single process.